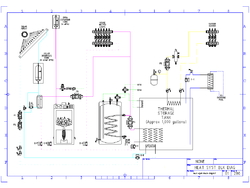

Bringing this thread back up as I've finally gotten my initial layout diagram done... Figured I'd post it and see what people thought. The attached is a .png file that I hope is legible - it looks nice as a .dxf, but I can't post those... (If you want that version, send me a PM w/ an e-mail address...)

I know it is complex, but let me see if I can explain it - if any one sees any glitches, please let me know.

SOLAR LOOP:

Our house has several attic spaces due to it's design, and one is in the lower half of the roof, which allows the use of a closed "drainback" type system with the tank mounted just below the collectors, minimizing the "lift height" required to fill them. It will slightly reduce the maximum size of the array that I could use, but it will allow me to avoid using glycol in that loop, and reduces the potential problems caused by stagnation, as the collectors would be filled with air in such a condition, rather than water. It is something I've seen in both Siegenthaler articles and on the Caleffi website.

P1 and P2 are in series, both operate at startup, but once the system is flowing, one can carry the load so the other is shut down - It may be worth making one of them speed controled to better match the panel output. The water to fill the array comes from the drainback tank, and the air in the array is displaced into the tank. Note that this system is sealed and pressurized to avoid O2 issues. When the circs shut off, the solar collectors drain back to the tank, and the air goes up to the array. The drainback tank also does duty as an expansion tank and air separator.

If the house is calling for heat, and the array is hotter than the house loops require, Z-A switches to force flow through the plate exchanger, which feeds the house loops via P3, Z-F and Z-H, otherwise it bypasses.

If the house loops don't need the heat, and / or if the return is warmer than the bottom of the thermal storage tank, Z-B sends water through the storage tank coil, otherwise it bypasses.

(I may add a third loop to the hot water storage tank, using a similar logic - not sure if it would be justifiable)

If neither load is cooler than the solar array, shut it down or modulate the circ for a lower flow rate / higher temp.

The idea is to send the solar output to the lowest temperature demand that can use it, as the lower the operating temperature, the more efficient the array is.

By having heat exchangers going to both the house loop directly and the storage tank, I can still use the solar array for house heating, even if the storage tank is hotter than the array. My theory is that I would mostly be building fires in the late afternoon or at night, when the array is shut down, and doing house heating and storage charging. In the day, the boiler would be burned out and cold, so by heating off the array and leaving the charged storage alone, I should get more time out of the storage before needing to build the next fire.

BOILER LOOP:

The boiler loop is pressurized by an OPEN expansion tank in our highest attic space - between 20 and 30 feet above the boiler room. This should give a 10-15psi working pressure at the boiler, but as the system is "open" avoid the stupid MA requirement for an ASME "H" stamp boiler. :coolsmirk: (This per Chris @ BioHeat)

If heat is being supplied by the boiler, or the solar heat exchanger, P3 runs, sending the heat to the house loops (controlled by Z-H), the DHW indirect (controlled by Z-J) or the main storage tank coil (controlled by Z-K). If running off the storage tank, P4 runs reversing the direction of flow in the main branch. P3 and P4 should probably be speed controlled. If P3 especially is speed controlled low enough, then it avoids the need for a Termovar or other boiler return protection - the pump won't pull more heat out of the boiler than it's making...

Note that right now I am showing the house loops as a single set of radiant loops controlled by Z-H - this is mostly because I haven't really tried to get the house side down on paper yet... In practice, I'm sure there will be many house circuits, each with their own zone-valve - however I don't think this will change the basic concept any.

DHW LOOP:

I'm swiping NoFossil's idea here of using dual mixing valves in order to get the most out of our hot water - when there is a hot water call, the makeup water to the indirect tank and the mix water to the first mix valve is pre-heated by a small coil in the storage tank, thus reducing the amount of peak temperature water pulled from the indirect tank. The second mix valve adds in cold DHW to give the final 120* output. (In theory if the storage tank were hot enough, there would be NO draw on the indirect...

GARAGE LOOP:

Simple standard style glycol loop to feed an occasional demand to warm up the garage - If I have to work out there I don't want to freeze my a(natomy) off... The heater will probably be a "Modine" style, but again the concept doesn't change...

POOL LOOP:

The place I have in mind for the storage tank is very close to our pool - it seems ideal for a gravity loop from the storage tank to the center of a sidearm type exchanger, with the outside tied into the swimming pool filter circuit... Z-X would control this loop during swimming season, when the pool is closed, simply opening the valve at the top of the loop will let it drain and shut off the flow.

So how does it look?

Gooserider

I know it is complex, but let me see if I can explain it - if any one sees any glitches, please let me know.

SOLAR LOOP:

Our house has several attic spaces due to it's design, and one is in the lower half of the roof, which allows the use of a closed "drainback" type system with the tank mounted just below the collectors, minimizing the "lift height" required to fill them. It will slightly reduce the maximum size of the array that I could use, but it will allow me to avoid using glycol in that loop, and reduces the potential problems caused by stagnation, as the collectors would be filled with air in such a condition, rather than water. It is something I've seen in both Siegenthaler articles and on the Caleffi website.

P1 and P2 are in series, both operate at startup, but once the system is flowing, one can carry the load so the other is shut down - It may be worth making one of them speed controled to better match the panel output. The water to fill the array comes from the drainback tank, and the air in the array is displaced into the tank. Note that this system is sealed and pressurized to avoid O2 issues. When the circs shut off, the solar collectors drain back to the tank, and the air goes up to the array. The drainback tank also does duty as an expansion tank and air separator.

If the house is calling for heat, and the array is hotter than the house loops require, Z-A switches to force flow through the plate exchanger, which feeds the house loops via P3, Z-F and Z-H, otherwise it bypasses.

If the house loops don't need the heat, and / or if the return is warmer than the bottom of the thermal storage tank, Z-B sends water through the storage tank coil, otherwise it bypasses.

(I may add a third loop to the hot water storage tank, using a similar logic - not sure if it would be justifiable)

If neither load is cooler than the solar array, shut it down or modulate the circ for a lower flow rate / higher temp.

The idea is to send the solar output to the lowest temperature demand that can use it, as the lower the operating temperature, the more efficient the array is.

By having heat exchangers going to both the house loop directly and the storage tank, I can still use the solar array for house heating, even if the storage tank is hotter than the array. My theory is that I would mostly be building fires in the late afternoon or at night, when the array is shut down, and doing house heating and storage charging. In the day, the boiler would be burned out and cold, so by heating off the array and leaving the charged storage alone, I should get more time out of the storage before needing to build the next fire.

BOILER LOOP:

The boiler loop is pressurized by an OPEN expansion tank in our highest attic space - between 20 and 30 feet above the boiler room. This should give a 10-15psi working pressure at the boiler, but as the system is "open" avoid the stupid MA requirement for an ASME "H" stamp boiler. :coolsmirk: (This per Chris @ BioHeat)

If heat is being supplied by the boiler, or the solar heat exchanger, P3 runs, sending the heat to the house loops (controlled by Z-H), the DHW indirect (controlled by Z-J) or the main storage tank coil (controlled by Z-K). If running off the storage tank, P4 runs reversing the direction of flow in the main branch. P3 and P4 should probably be speed controlled. If P3 especially is speed controlled low enough, then it avoids the need for a Termovar or other boiler return protection - the pump won't pull more heat out of the boiler than it's making...

Note that right now I am showing the house loops as a single set of radiant loops controlled by Z-H - this is mostly because I haven't really tried to get the house side down on paper yet... In practice, I'm sure there will be many house circuits, each with their own zone-valve - however I don't think this will change the basic concept any.

DHW LOOP:

I'm swiping NoFossil's idea here of using dual mixing valves in order to get the most out of our hot water - when there is a hot water call, the makeup water to the indirect tank and the mix water to the first mix valve is pre-heated by a small coil in the storage tank, thus reducing the amount of peak temperature water pulled from the indirect tank. The second mix valve adds in cold DHW to give the final 120* output. (In theory if the storage tank were hot enough, there would be NO draw on the indirect...

GARAGE LOOP:

Simple standard style glycol loop to feed an occasional demand to warm up the garage - If I have to work out there I don't want to freeze my a(natomy) off... The heater will probably be a "Modine" style, but again the concept doesn't change...

POOL LOOP:

The place I have in mind for the storage tank is very close to our pool - it seems ideal for a gravity loop from the storage tank to the center of a sidearm type exchanger, with the outside tied into the swimming pool filter circuit... Z-X would control this loop during swimming season, when the pool is closed, simply opening the valve at the top of the loop will let it drain and shut off the flow.

So how does it look?

Gooserider