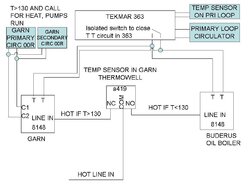

On my oil boiler, I have the Honeywell 8148 controller. It receives the TT terminals (demand for heat) which then fires the burner...and the photocell is integrated. Now, a Tekmar 363 is used to send the call for heat to the 8148 on the oil boiler. When the primary loop reaches temp, the Tekmar removes the call for heat and the oil burner stops.

Is this TT input just a 24V AC input that closes a relay on the 8148?

I seem to read conflicting information....it seems that is exactly how your average thermostat works...yet the 363 controller manual seems to tell me that the T T terminals just close a switch within the 363? In a hurry the other day I tried to measure across the TT terminals on the 8148 when it was firing and I didn't seem to measure 24V (or anything)....so that just added more confusion to the mix.

I have the new Garn plumbed...and this week I hope to flood and fire. Yeah! For controls, I plan to use a a419ABC to monitor the temp of the GARN, and if BELOW the setpoint, the a419 will energize the 8148 line supply...so a call for heat will burn oil. If the Garn is over 130, then the 8148 will not be energized by a separate relay will be, and therefore the call for heat will turn on the circulators around the Garn. In either case, the 363 will not be changed...so it just sends out the call for heat and removes it when satisfied. I just have to run the line power to the 8148 through the a419, run the TT input going to the oil boiler to an additional relay, and then power this relay from the "other contact" on the a419. Seems like a simple and cheap way to accomplish my needs. The 363 will keep managing the actual primary loop temp...without changing anything in its wiring.

Thanks to all!

Is this TT input just a 24V AC input that closes a relay on the 8148?

I seem to read conflicting information....it seems that is exactly how your average thermostat works...yet the 363 controller manual seems to tell me that the T T terminals just close a switch within the 363? In a hurry the other day I tried to measure across the TT terminals on the 8148 when it was firing and I didn't seem to measure 24V (or anything)....so that just added more confusion to the mix.

I have the new Garn plumbed...and this week I hope to flood and fire. Yeah! For controls, I plan to use a a419ABC to monitor the temp of the GARN, and if BELOW the setpoint, the a419 will energize the 8148 line supply...so a call for heat will burn oil. If the Garn is over 130, then the 8148 will not be energized by a separate relay will be, and therefore the call for heat will turn on the circulators around the Garn. In either case, the 363 will not be changed...so it just sends out the call for heat and removes it when satisfied. I just have to run the line power to the 8148 through the a419, run the TT input going to the oil boiler to an additional relay, and then power this relay from the "other contact" on the a419. Seems like a simple and cheap way to accomplish my needs. The 363 will keep managing the actual primary loop temp...without changing anything in its wiring.

Thanks to all!