To my disappointment, the primary pump on the EKO is making some new noises, it sounds as if its about to go south. I have 2 questions

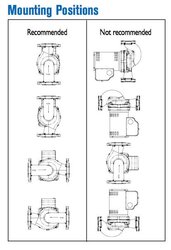

1) Is the way I mounted the pump causing its early demise? (see photo)

2) would a Taco 1400-20 be a better pump for the constant running this pump does and will it bolt easily in place of the 0013 ?

1) Is the way I mounted the pump causing its early demise? (see photo)

2) would a Taco 1400-20 be a better pump for the constant running this pump does and will it bolt easily in place of the 0013 ?