OK, this is new thread since the other one on hearth materials is getting so long...

A comment about using air spaces and R-Values for hearth construction. I would not suggest using the common R-value of air space to design a stove hearth for the following reason - R and K factors differ depending on the temperature and "type" of heat we are talking about!

When R values are calculated in normal house constructions, it goes without saying that they are talking about temperatures of -20 to 140 degrees F. They are also talking about generalized radiation and heat transfer.

BUT

When we are talking about a stove hearth, we are dealing with DIRECT and invisible radiant energy waves, which pass right though air as if it was not there at all. The means it is possible that there is ZERO R value in this application. Let me explain....if the R value of Air was as high as suggested, it would be OK to simply raise the stove 1" up on blocks under the legs and then put a thin tile on the floor - BUT NO WAY WOULD THIS WORK.

Check out this quote from a site discussion heat transfer:

HEAT LOSS THROUGH AIR

There is no such thing as a “dead” air space as far as heat transfer is concerned, even in the case of a perfectly airtight compartment such as a thermos bottle. Convection currents are inevitable with differences in temperature between surfaces, if air or some other gas is present inside. Since air has some density, there will be some heat transfer by conduction if any surface of a so-called “dead” air space is heated. Finally, radiation, which accounts for 50% to 80% of all heat transfer, will pass through air (or a vacuum) with ease, just as radiation travels the many million miles that separate the earth from the sun.

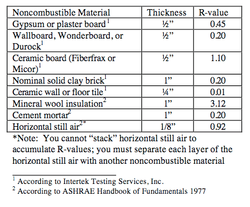

Ok, so that says what I am trying to get at - that radiant heat will not be stopped by air to any degree. This does not mean that air has no place at all in hearth construction, but just that folks should NOT use that R-Value as the guide. As a for-instance, I would think that a hearth built of:

1 sheet of cement board 1/2"

then the hi-hat metal channels

then 2 sheets of 1/2" as the underlayment

would be quite effective, but when all is said and done, why not use 4 layers of cement board instead?

Comments?

A comment about using air spaces and R-Values for hearth construction. I would not suggest using the common R-value of air space to design a stove hearth for the following reason - R and K factors differ depending on the temperature and "type" of heat we are talking about!

When R values are calculated in normal house constructions, it goes without saying that they are talking about temperatures of -20 to 140 degrees F. They are also talking about generalized radiation and heat transfer.

BUT

When we are talking about a stove hearth, we are dealing with DIRECT and invisible radiant energy waves, which pass right though air as if it was not there at all. The means it is possible that there is ZERO R value in this application. Let me explain....if the R value of Air was as high as suggested, it would be OK to simply raise the stove 1" up on blocks under the legs and then put a thin tile on the floor - BUT NO WAY WOULD THIS WORK.

Check out this quote from a site discussion heat transfer:

HEAT LOSS THROUGH AIR

There is no such thing as a “dead” air space as far as heat transfer is concerned, even in the case of a perfectly airtight compartment such as a thermos bottle. Convection currents are inevitable with differences in temperature between surfaces, if air or some other gas is present inside. Since air has some density, there will be some heat transfer by conduction if any surface of a so-called “dead” air space is heated. Finally, radiation, which accounts for 50% to 80% of all heat transfer, will pass through air (or a vacuum) with ease, just as radiation travels the many million miles that separate the earth from the sun.

Ok, so that says what I am trying to get at - that radiant heat will not be stopped by air to any degree. This does not mean that air has no place at all in hearth construction, but just that folks should NOT use that R-Value as the guide. As a for-instance, I would think that a hearth built of:

1 sheet of cement board 1/2"

then the hi-hat metal channels

then 2 sheets of 1/2" as the underlayment

would be quite effective, but when all is said and done, why not use 4 layers of cement board instead?

Comments?