Heat the water above 150 last night that is. I got home last night at about 5:30 and the tanks and boiler were at 145 with a fire going. I added a couple more pieces and check it again a little while later it's at 141. The tekmar is now looking for both boilers to be running, the oil is unplgged. So I close the ball valves to the tanks down about half way and the bypass open 1/2 way and added more wood. An hour later 143. So I shut the valves to the tanks and open the bypass. So loading the boiler every 2 hours and supplying all the heat to the house it never got above 145 last night. I can't load more then 5-6 splits in because it will overfire. I'm fed up with this hunk of steel!

The little New Yorker that couldn't!

- Thread starter Blevesque

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Eric Johnson

Mod Emeritus

If it's overfiring and the tank/zones are not getting enough hot water to reach and maintain temp, then it sounds to me like you've got a problem with your piping and/or pump sizing.

If your boiler was going all-out and couldn't get up to temp in the pressure vessel, then your boiler would be undersized.

If your boiler was going all-out and couldn't get up to temp in the pressure vessel, then your boiler would be undersized.

Hi Eric, thanks for the reply. My oil boiler is the same size as the wood boiler and that maintains the house no problem. My piping layout I'm assuming is an issue but last night I by-passed the tanks completely and still could not keep up. I am going to grap an infrared thermometer and check the return and supply of the wood boiler. I'll probably increase the low limit from 140 to say 160. I'll draw up a diagram of my piping layout. And post that up also. Thanks, Brian

steam man

Minister of Fire

Wow. It looks like you need 4 pumps to run at one time just to heat 1 zone. I can see enough points to get your heat balance out of wack. It looks like the indirect has its own primary/secondary and the zones are a sub-primary/secondary loop to that. Try and take some good temp readings at all the loop's supply/returns. It looks to me like you need to look at what is flowing through each circuit to get a good heat balance. One thing about the size of the wood boiler is that taking efficiency into account it will never beat the oil boiler at putting out btu's. It may be a little small for sub freezing temps but it should run better at all other times. Getting the return temp up should help the wood boiler stay ahead of the system somewhat.

Mike

Mike

Hi Mike, yes 4 pumps need to run to get heat out to the house. Pump 1 would be the system pump (the pump just after air scoop/expansion tank) that pump turns on when there a call for heat to the house via the t-stats. Pump 2 would be the pump on the return of the wood or the one on the oil. Pump 3 would be the radiant injection pump. Pump 4-8 would be the pumps for each radiant zone. I just got a bachrach kit and infrared thermometer so I can do some monitoring tonight. I'll log the data down and see if I can figure out what the heck is going on. Brian

Bartman

Member

Sounds like something is definitely wrong here my old New Yorker WC-120, (the model before your's) cranks. This past year I have actuall disabled the automatic operation to save wood and lower the output, I pretty much run it idled all day, with all air shut down. From time to time I'll give it air to run it hotter. My piping is totally different than your's, I run the boilers in series.

hayrack

Member

Bartman

Member

Plumbit

New Member

What size piping did you use out of the wood boiler? 1/2 = 25,000 3/4 _40,000 1=80,000 11/4 =120,000 the piping is like wire size the smaller the less amps but can still have voltage. Your race cars increase exhaust size and add bigger intakes to add HP. Just a another opinion to check out

Thanks for the replys everyone, sorry i've taken so long to reply. I took friday off so I could be home to keep the house warm with wood and to see if I could figure out what is wrong with this thing. So here is what I've got. The first thing I did Thursday night when I got home was to check the draft because I was suspecting it to be very high. With the fire going good, the combustion fan at 1/4" open and the barometric damper closed to about 25% open, this would be normal operation draft was -.02". OK not what I was expecting! So I opened the Baro up to 100% open draft was -.04" and within 2 minutes I got flames in the stack. Outside temp was about -6 F and a little wind. Wood boiler was still not keeping up so I plugged the oil back in to get everything up to temp and see if the wood could maintain after that. It did to a degree as long as I made sure i would load more wood in every 2 hours tops. 4-5 splits 4"-5" in size max. any more and flames in the flue. I also set the low limit to 150. Return water temp into the boiler was 139 and supply out was 149. The wood boiler pump is a Taco 007. I closed the ball valve on the discard side of the pump to about 50% and got about 12 deg delta T. This seems low to me.. I forgot to mention all my piping is done in 1 1/2" black. So there you have it, if anyone has any suggestion or ideas please I am all ears. If I can't figure this thing out it will be going to the scrap pile! Brian

I forgot to ask is anyone running a new yorker with storage. I'd be curious to know how yours runs when it is run hot with no idling. Everyone that I've talked to and even anyone on here that talks about theres, is always saying that there is in idle more times then not. Is anybodys new yorker not in idle all the time. I also forgot to mention that my magnetic stack thermometer is about 500 degrees off. Stack thermo was reading 275 infra red surface reading was 409 and inside infra red surface reading was 780.

steam man

Minister of Fire

Obviously it seems as if your not keeping up with the heat load. Closing down the flow with the discharge valve at the 007 would seem to keep the temp way down if all the zone pumps were running demanding heat. I would shut off all the zones the indirect and the tanks, open the 007 valve all the way and fire the primary loop. If that gets to temp easily enough, start the primary pump on the indirect/zone loop. Once that gets to temp, start the primary pump on the zone loop. (I have to keep looking at the drawing to make sure where I am). If that's ok, start one zone pump at a time and see how it does. Have you ever tried just circulating to the storage tanks and seeing how long it takes to get them up the temp? You could get a good idea what the WC 130 is actually putting out if you took temps before and after. Measuring over 1 hour would seem to be a good comparison. This kind of reminds me when I put a load bank on a large generator set to see what the thing is actually putting out.

Mike

Mike

Hi Mike, It appears that it will keep up all the way down to 0 to -5 if and only if the boiler and tanks are above 145-150 if it drops below that it can't get over the treshhold and will keep bumping on the low limit. I also raised my low limit to 165 it only did the same. I thought that the way I piped my tanks in being the reason, but I actually think it's probably best for it. The way I have then piped they are essentially a buffer tank rather then a storage tank because the water has to go through them to get to the system unless I by-pass the tanks. Maybe I'm wrong (most likely). Brian

slowzuki

Minister of Fire

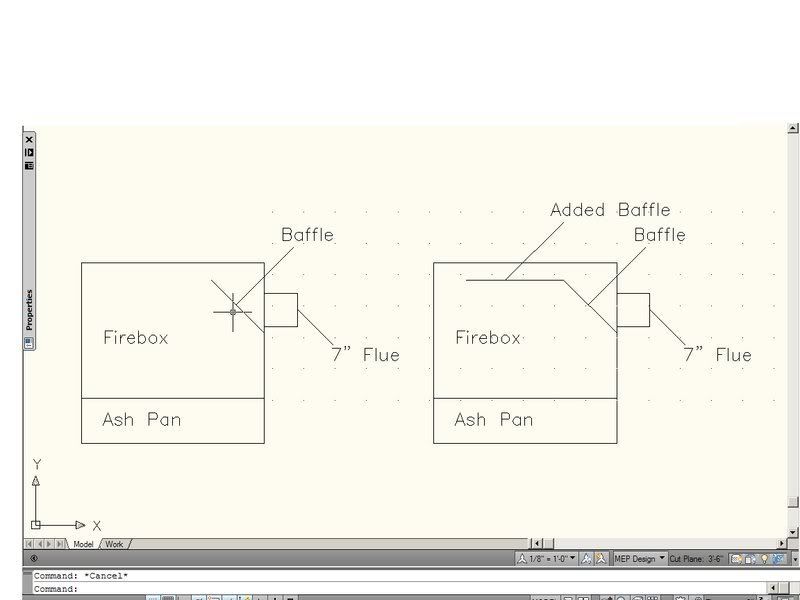

Slowzuki, there is no heat exchanger in the 130, I believe the older models had the heat exchangers. The inside of mine is just a big box with a 12" x the width of the fire box 1/4" steel baffle that goes up at 45 deg.

Here is a crude drawing of a side view. The one on the left is the current. On the right is what I had in mind of doing. Brian

Here is a crude drawing of a side view. The one on the left is the current. On the right is what I had in mind of doing. Brian

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 522

- Replies

- 16

- Views

- 5K

- Replies

- 2

- Views

- 451

- Replies

- 8

- Views

- 837