Time for a tips and tricks thread! List one you like.

- Thread starter smokinj

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Backwoods Savage

Minister of Fire

Backwoods Savage said:Okay Jay, here's a tip. Split vertically.

lol I took that advice in 2008 didn't take me long to listen to that! Just have not got the seat perfected yet........

mayhem

Minister of Fire

Tip: don't stick a bees nest in your coveralls.

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

Jags said:Tip: don't stick a bees nest in your coveralls.

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

OH YEA....Walnut will burn hackberry hickory. Now also talking forsner bits up to 3-1/2 inchs, and tennon makers is what I am doing. lol

smokinjay said:Jags said:Tip: don't stick a bees nest in your coveralls.

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

OH YEA....Walnut will burn hackberry hickory. Now also talking forsner bits up to 3-1/2 inchs, and tennon makers is what I am doing. lol

Yeah, I use those bits on occasions to, but I don't get a burn from them. Hmmm...maybe sharpness??

Jags said:smokinjay said:Jags said:Tip: don't stick a bees nest in your coveralls.

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

OH YEA....Walnut will burn hackberry hickory. Now also talking forsner bits up to 3-1/2 inchs, and tennon makers is what I am doing. lol

Yeah, I use those bits on occasions to, but I don't get a burn from them. Hmmm...maybe sharpness??

Grab a piece of walnut a 3-1/2 er and set the video up......I want to see this! Even the smaller one will drive faster and a cleaner hole with the lard.

smokinjay said:Jags said:smokinjay said:Jags said:Tip: don't stick a bees nest in your coveralls.

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

OH YEA....Walnut will burn hackberry hickory. Now also talking forsner bits up to 3-1/2 inchs, and tennon makers is what I am doing. lol

Yeah, I use those bits on occasions to, but I don't get a burn from them. Hmmm...maybe sharpness??

Grab a piece of walnut a 3-1/2 er and set the video up......I want to see this! Even the smaller one will drive faster and a cleaner hole with the lard.

Oh - I don't doubt you a bit. I was just thinking that I punched two holes with a 2" on some oak (making a couple of sliding drawers) and now that I think about it, there probably was a little burn on the edges, but I was also thinking that the bit was dull. Maybe I don't pay much attention because I always have to hand finish sanding.

Got any tennon makers you wanna send to me??

Jags said:smokinjay said:Jags said:smokinjay said:Jags said:Tip: don't stick a bees nest in your coveralls.

Hey Jay, why you gotta lube wood bits?? (serious question). Are you getting wood burning??

OH YEA....Walnut will burn hackberry hickory. Now also talking forsner bits up to 3-1/2 inchs, and tennon makers is what I am doing. lol

Yeah, I use those bits on occasions to, but I don't get a burn from them. Hmmm...maybe sharpness??

Grab a piece of walnut a 3-1/2 er and set the video up......I want to see this! Even the smaller one will drive faster and a cleaner hole with the lard.

Oh - I don't doubt you a bit. I was just thinking that I punched two holes with a 2" on some oak (making a couple of sliding drawers) and now that I think about it, there probably was a little burn on the edges, but I was also thinking that the bit was dull. Maybe I don't pay much attention because I always have to hand finish sanding.

Got any tenon makers you wanna send to me??

Try it....Now with tenon making it makes even more of an improvement. This is a trick out of metal shop for sure, but sure helps in wood as well. (My forsner are brand new) Not the best quality though.

smokinjay said:Try it....Now with tenon making it makes even more of an improvement. This is a trick out of metal shop for sure, but sure helps in wood as well. (My forsner are brand new) Not the best quality though.

I don't remember the brand, but mine are probably 40 yrs old.

I had often thought of trying my hand at some log furniture.

Tip: if working in a cool/cold shop, carry the wood glue in your pocket to keep it warm.

Jags said:smokinjay said:Try it....Now with tenon making it makes even more of an improvement. This is a trick out of metal shop for sure, but sure helps in wood as well. (My forsner are brand new) Not the best quality though.

I don't remember the brand, but mine are probably 40 yrs old.

I had often thought of trying my hand at some log furniture.

Tip: if working in a cool/cold shop, carry the wood glue in your pocket to keep it warm.

LOL I can drive those tenon so tight I think they would be fine without glue but still give it a small shot.

Thistle

Minister of Fire

One old trick our ancestors did was have the tenon dry & mortice a wee bit green,it would then shrink up tight.Lock in place with a tapered dowel or peg,then cut off flush.

Thistle said:One old trick our ancestors did was have the tenon dry & mortice a wee bit green,it would then shrink up tight.Lock in place with a tapered dowel or peg,then cut off flush.

They where really thinking ahead on that project....Have you done any of the fire side stool's?

bogydave

Minister of Fire

When in doubt if you should split a 3 to 4" +/- thick round

Split it part way, it'll dry better in the middle & not be a real small split.

Split it part way, it'll dry better in the middle & not be a real small split.

bogydave

Minister of Fire

Sand paper cutting jig.

Draw a line on a board or piece left over MDF 6" X 12" from the edge as wide as your sanding block.

Screw a hack saw blade to a board with the teeth along the line.

Slide the sandpaper under the blade to the edge of the board & tear it off.

The Right width every time.

Draw a line on a board or piece left over MDF 6" X 12" from the edge as wide as your sanding block.

Screw a hack saw blade to a board with the teeth along the line.

Slide the sandpaper under the blade to the edge of the board & tear it off.

The Right width every time.

Attachments

bogydave

Minister of Fire

Is your Square "Square"?

Not all squares are square. Here's a trick

Use a good straight edge clamped to flat surface.

Put the square on the straight edge & draw a line. Roll the square over, keeping the same edge to the straight edge, & see if the line matches up.

If yes its OK If no you can adjust it with a hammer & punch:

If the angle is to tight (< 90 deg), put a few punch marks on the inside angle, this stretches the metal on the inside angle a little & opens the angle.

If the angle is open (> 90 deg), put a few punch marks on the outside corner. This stretches th metal on the outside angle & close the angel a little.

Open the angle picture.

I learned that opening it up is allot easier than closing it. So go slowly

I hammered down the punch mark which help move it a little also.

Not all squares are square. Here's a trick

Use a good straight edge clamped to flat surface.

Put the square on the straight edge & draw a line. Roll the square over, keeping the same edge to the straight edge, & see if the line matches up.

If yes its OK If no you can adjust it with a hammer & punch:

If the angle is to tight (< 90 deg), put a few punch marks on the inside angle, this stretches the metal on the inside angle a little & opens the angle.

If the angle is open (> 90 deg), put a few punch marks on the outside corner. This stretches th metal on the outside angle & close the angel a little.

Open the angle picture.

I learned that opening it up is allot easier than closing it. So go slowly

I hammered down the punch mark which help move it a little also.

Attachments

bogydave

Minister of Fire

Quick miter grove clamp.

Get a 3/8" washer that just fits in the bottom of the miter slot, countersink one side of the washer with a 1/2" bit, epoxy a flat head 1/4" bolt to the washer, clamp in miter slot till dry. Tighten wing nut snug to hold jigs, feather boards etc.

Get a 3/8" washer that just fits in the bottom of the miter slot, countersink one side of the washer with a 1/2" bit, epoxy a flat head 1/4" bolt to the washer, clamp in miter slot till dry. Tighten wing nut snug to hold jigs, feather boards etc.

Attachments

bogydave said:Quick miter grove clamp.

Get a 3/8" washer that just fits in the bottom of the miter slot, countersink one side of the washer with a 1/2" bit, epoxy a flat head 1/4" bolt to the washer, clamp in miter slot till dry. Tighten wing nut snug to hold jigs, feather boards etc.

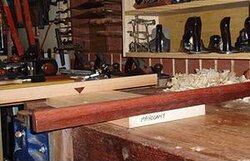

Nice tips dave...Got one for you (maybe) is your edger dead on planer or sable saw flat? Hears one wear its all eye ball Winding sticks! I use them mainly for bigger longer slabs.

Amazing how well it works on an edger planer setting up the table. You can measure all day long and never do aswell as your eyeball...lol

Attachments

gpcollen1

Minister of Fire

bogydave said:Sand paper cutting jig.

Draw a line on a board or piece left over MDF 6" X 12" from the edge as wide as your sanding block.

Screw a hack saw blade to a board with the teeth along the line.

Slide the sandpaper under the blade to the edge of the board & tear it off.

The Right width every time.

Now that is a good one..

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 573

- Replies

- 2

- Views

- 271

- Replies

- 0

- Views

- 306

- Replies

- 6

- Views

- 676