Ah.. the best laid plans....

I downed a pretty good sized Water Oak today. Standing dead. I noticed it about a month ago when I spotted lots of downed limbs. "Sweet!" says I. It's only about 20 feet from a trail big enough for my 8N tractor as well as my smaller lawn tractor and wagon. The tree was surrounded by thick brush and vines and scrub trees. I spent an hour cleaning out an area where I wanted to drop it, as well as a work area immediately behind the tree and an escape path running 90 degrees from my drop zone. Wanted a safe working environment.

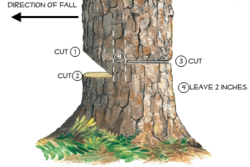

With a freshly sharpened chain my MS 390 tore into the tree trunk. I cut out my front wedge and moved around to make my back cut. Dang! I was not expecting to get pinched on the back cut. Only then did I realize the tree had just the slightest back lean to it. I drove a couple of wedges in to free my saw then pounded them in a lot further, opening up that back cut. I couldn't get the saw back into the back cut but it was already deep enough so I moved to the front again to widen the wedge cut. Slowly, the tree starts to fall... exactly 180 degrees from my intended drop zone. Now, I have not dropped a great number of trees but the ones I have have always fallen exactly where I wanted them. The tree fell into an area thick with vines, scrub, short cedars, yaupon, etc. I cleared the area somewhat and cut the trunk into several approximately eight foot lengths. I hope to be able to drag them out with my tractor and a chain. Otherwise, I'll buck them to 20 inches and bring one out at a time, use the stump to split them and perhaps stack them right there and leave them there next to the trail for the next two years or so.

Pictures below:

To get an idea of the height of this tree, if you look toward the bottom of the trunk you might see a white glove I hung up at a height equal to the top of my head. Call it six feet. I'm guessing the tree is around 45 feet tall. I can barely reach around it and place my hands together. About 16 inches diameter.

The next two pics are of the downed tree, already cut into sections. The top is stuck in other trees (visible in last pic) but I think I can get it down fairly easy.

This pic shows pretty clearly the crap the tree fell into.

I downed a pretty good sized Water Oak today. Standing dead. I noticed it about a month ago when I spotted lots of downed limbs. "Sweet!" says I. It's only about 20 feet from a trail big enough for my 8N tractor as well as my smaller lawn tractor and wagon. The tree was surrounded by thick brush and vines and scrub trees. I spent an hour cleaning out an area where I wanted to drop it, as well as a work area immediately behind the tree and an escape path running 90 degrees from my drop zone. Wanted a safe working environment.

With a freshly sharpened chain my MS 390 tore into the tree trunk. I cut out my front wedge and moved around to make my back cut. Dang! I was not expecting to get pinched on the back cut. Only then did I realize the tree had just the slightest back lean to it. I drove a couple of wedges in to free my saw then pounded them in a lot further, opening up that back cut. I couldn't get the saw back into the back cut but it was already deep enough so I moved to the front again to widen the wedge cut. Slowly, the tree starts to fall... exactly 180 degrees from my intended drop zone. Now, I have not dropped a great number of trees but the ones I have have always fallen exactly where I wanted them. The tree fell into an area thick with vines, scrub, short cedars, yaupon, etc. I cleared the area somewhat and cut the trunk into several approximately eight foot lengths. I hope to be able to drag them out with my tractor and a chain. Otherwise, I'll buck them to 20 inches and bring one out at a time, use the stump to split them and perhaps stack them right there and leave them there next to the trail for the next two years or so.

Pictures below:

To get an idea of the height of this tree, if you look toward the bottom of the trunk you might see a white glove I hung up at a height equal to the top of my head. Call it six feet. I'm guessing the tree is around 45 feet tall. I can barely reach around it and place my hands together. About 16 inches diameter.

The next two pics are of the downed tree, already cut into sections. The top is stuck in other trees (visible in last pic) but I think I can get it down fairly easy.

This pic shows pretty clearly the crap the tree fell into.