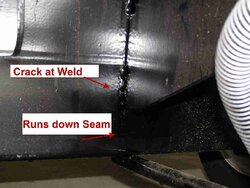

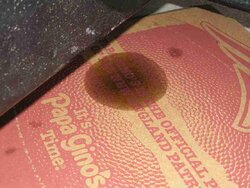

Anyone hearing about hairline tank cracks. I bought this from Lowes, May of 2009, last fall split about 8 cords, noticed a spot in the garage. Tank split horizontally between the welds that hold the motor plate to the tank (bad design).

Was replaced in 11/2009 for free....Just noticed a spot in the garage today, new tanks is cracked. Same place, almost a year to the day. This time I split about 16 cords. Splits great, though had to beef up some of the hardware. I need to check on the value recall, look at Troy Built site if you have not heard. I saw some one already posted.

What's the word out there. I only tow it around my own yard with a lawn tracker, and store it inside Next year my 2 year warranty is up, could get expensive at a tank a year, or I have to take up welding.

Is it just me.

Was replaced in 11/2009 for free....Just noticed a spot in the garage today, new tanks is cracked. Same place, almost a year to the day. This time I split about 16 cords. Splits great, though had to beef up some of the hardware. I need to check on the value recall, look at Troy Built site if you have not heard. I saw some one already posted.

What's the word out there. I only tow it around my own yard with a lawn tracker, and store it inside Next year my 2 year warranty is up, could get expensive at a tank a year, or I have to take up welding.

Is it just me.