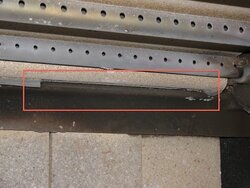

I was cleaning out the ashes today and I found a piece of something which didn't look like wood in the ashes. Further inspection revealed that piece of the stove had broken off and then I found another piece cracked. Please let me know how serious this is. I have attached pictures.

Uh Oh, broken part on my new Oslo.

- Thread starter RSNovi

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.