Hello all,

This is my first post on hearth.com - I have been coming to this website for information, especially when we were looking for a wood stove for our home in Austin, TX. Our house doesn't have any real heating system, and Austin can drop down to 30's during the winter especially nighttime. We finally purchased an used 1993 Jotul FireLight, in an excellent shape. Some threads were also helpful with purchasing chimney pipes and stove pipes - this whole wood stove and pipes research took me a while, but wouldn't be possible without some members' input on this forum. Thank you all.

I have two questions and I hope you guys can help me out here, as I'm having a person come in on December 30th to install and I want to make sure I get the installation done right. He was referred to me from a local wood stove store, but I want double check and make sure things get done the right way...

Our wood stove will be "through a wall" installation (with thimble).

1. My roof eave is approximately 14" or 16" from the wall (it's too high for me to get an accurate measurement). Let's assume that it is 14" - the installer recommended that we put a chimney through the eave instead of getting two 30* elbows. My chimney is double walled, 6" inch with 8" external diameter. Is this normal setup? I can imagine this set up being more straightforward and neater, but my biggest concern is safety. I couldn't find anything about the minimum length of eave allowable for chimney pipe to go through it.

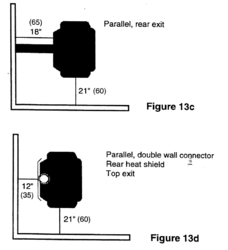

2. The manual book says 18" clearance from the back of stove to combustible wall. I have 12" - 16" adjustable stove pipe and I'd like to have the stove set closer to the wall than 18". If we were to take the drywall off, add 1" ceramic spacer, sheet rock and cover it with tiles. How much closer can I get our Jotul to this wall? Second option is to leave drywall there, and add the same ceramic 1" spacer between drywall and 1/4 steel sheet - would this work as well? Would I be able to bring the stove a bit closer to the wall? We already have some homemade welded steel furnishings in our house and they would go with a steel wall behind the stove nicely. It would be nice to be able to set the stove 12" away from the wall, if possible as Jotul Firelight is BIG.

Danke,

Daniel

This is my first post on hearth.com - I have been coming to this website for information, especially when we were looking for a wood stove for our home in Austin, TX. Our house doesn't have any real heating system, and Austin can drop down to 30's during the winter especially nighttime. We finally purchased an used 1993 Jotul FireLight, in an excellent shape. Some threads were also helpful with purchasing chimney pipes and stove pipes - this whole wood stove and pipes research took me a while, but wouldn't be possible without some members' input on this forum. Thank you all.

I have two questions and I hope you guys can help me out here, as I'm having a person come in on December 30th to install and I want to make sure I get the installation done right. He was referred to me from a local wood stove store, but I want double check and make sure things get done the right way...

Our wood stove will be "through a wall" installation (with thimble).

1. My roof eave is approximately 14" or 16" from the wall (it's too high for me to get an accurate measurement). Let's assume that it is 14" - the installer recommended that we put a chimney through the eave instead of getting two 30* elbows. My chimney is double walled, 6" inch with 8" external diameter. Is this normal setup? I can imagine this set up being more straightforward and neater, but my biggest concern is safety. I couldn't find anything about the minimum length of eave allowable for chimney pipe to go through it.

2. The manual book says 18" clearance from the back of stove to combustible wall. I have 12" - 16" adjustable stove pipe and I'd like to have the stove set closer to the wall than 18". If we were to take the drywall off, add 1" ceramic spacer, sheet rock and cover it with tiles. How much closer can I get our Jotul to this wall? Second option is to leave drywall there, and add the same ceramic 1" spacer between drywall and 1/4 steel sheet - would this work as well? Would I be able to bring the stove a bit closer to the wall? We already have some homemade welded steel furnishings in our house and they would go with a steel wall behind the stove nicely. It would be nice to be able to set the stove 12" away from the wall, if possible as Jotul Firelight is BIG.

Danke,

Daniel

on the wood trim with a 600

on the wood trim with a 600 Each winter there is a house that burns down near us that is caused by a wood stove so I want to make sure my house is not the next one.

Each winter there is a house that burns down near us that is caused by a wood stove so I want to make sure my house is not the next one.