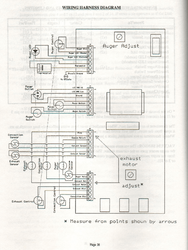

Got some work done finally on my new stove control panel.

Bought the switches, indicator lamps and other goodies.

Formed a piece of aluminum to replicate the original panel on the Whitfield 2T

Here is a piccy of the unit as far as I have it today.

Got the thing cut to fit in the stove like the original part

The lower large rocker switch is the main power and switches the neutral as well as the hot lead

The smaller rocker switch controls only power to the timer relay that feeds the auger motor (burner)

The red light will glow any time main power is on. Burner light will glow any time power is switched to the auger control relay.

The fuse is for the entire stove including the exhaust fan and the blower fan.

The red button is for the start sequence. (self explanatory)

The green lamp will glow any time the auger is on. (Blink on and off as the auger cycles)

The knob at the top is faked at present as I dont have the Pot for the fed relay timer yet.

The graphics (real deal stove control) are Possible and whatever,the panel will get a custom decal applied (local shop does that stuff) once the final parts are fit to the panel.

The draft/exhaust fan control and the room air blower control will be installed just in back of the control panel area in the side panel of the stove.

The control panel is just too small to allow for all the extra lights and the variable speed controls for the fans too.

The relay receptacles will fasten to the inside of the stove cabinet just behind the room air blower.

The side panel on this stove swings open easily with the removal of two scews and allows full access to the area for serviceing.

Still thrashing out the details on the draft fan speed contoller.

A triac speed control board is nice but adds a lot of complexity.

I found a company that makes a very nice small "Off the shelf" controller that they are sending me a sample of.

The room air fan control will likely end up being a standard casablanca fan contoller with manual stops placed on the knob to stop it from being turned OFF completely.

Once this setup is done the stove should have plenty of adjustments as well as parts that are off the shelf technology and can be replaced quickly.

The switches and lights are from Norvac and the control relays are coming from Precision timers.

Precision is also supplying the 5 position POT to control the fuel/heat range

Off time or burn time will range from 6 seconds on LOW to 2 seconds on HIGH

The actual feed time (auger on time) will be adjustable in the 1.5 second range

Currently with nut shells the stove really works well in the 5 second range for a nice medium setting and the 6 second range for a tiny spot fire. 3 seconds will get things up and heating right smartly.

The 2 second setting will likely never be used but the control comes with that resistor in it so ???

Hope someone finds all this interesting

Snowy

Bought the switches, indicator lamps and other goodies.

Formed a piece of aluminum to replicate the original panel on the Whitfield 2T

Here is a piccy of the unit as far as I have it today.

Got the thing cut to fit in the stove like the original part

The lower large rocker switch is the main power and switches the neutral as well as the hot lead

The smaller rocker switch controls only power to the timer relay that feeds the auger motor (burner)

The red light will glow any time main power is on. Burner light will glow any time power is switched to the auger control relay.

The fuse is for the entire stove including the exhaust fan and the blower fan.

The red button is for the start sequence. (self explanatory)

The green lamp will glow any time the auger is on. (Blink on and off as the auger cycles)

The knob at the top is faked at present as I dont have the Pot for the fed relay timer yet.

The graphics (real deal stove control) are Possible and whatever,the panel will get a custom decal applied (local shop does that stuff) once the final parts are fit to the panel.

The draft/exhaust fan control and the room air blower control will be installed just in back of the control panel area in the side panel of the stove.

The control panel is just too small to allow for all the extra lights and the variable speed controls for the fans too.

The relay receptacles will fasten to the inside of the stove cabinet just behind the room air blower.

The side panel on this stove swings open easily with the removal of two scews and allows full access to the area for serviceing.

Still thrashing out the details on the draft fan speed contoller.

A triac speed control board is nice but adds a lot of complexity.

I found a company that makes a very nice small "Off the shelf" controller that they are sending me a sample of.

The room air fan control will likely end up being a standard casablanca fan contoller with manual stops placed on the knob to stop it from being turned OFF completely.

Once this setup is done the stove should have plenty of adjustments as well as parts that are off the shelf technology and can be replaced quickly.

The switches and lights are from Norvac and the control relays are coming from Precision timers.

Precision is also supplying the 5 position POT to control the fuel/heat range

Off time or burn time will range from 6 seconds on LOW to 2 seconds on HIGH

The actual feed time (auger on time) will be adjustable in the 1.5 second range

Currently with nut shells the stove really works well in the 5 second range for a nice medium setting and the 6 second range for a tiny spot fire. 3 seconds will get things up and heating right smartly.

The 2 second setting will likely never be used but the control comes with that resistor in it so ???

Hope someone finds all this interesting

Snowy