I'm in the process of 'upgrading' from one old stove to another. My current small non-airtight stove doesn't make quite enough heat to heat my house, and doesn't even come close to burning all night. This is my ONLY heat source currently, BTW.

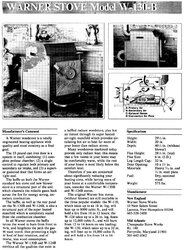

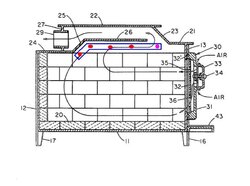

I've been given an old Warner that's been sitting in storage for the last 20 years. It's a bit rusty so it'll get sand blasted and painted. I'm considering adding secondary burn tubes per the attached pic. The BLUE is box tube down each side of stove. The RED are cross tubes with 3/16" holes every inch or two. The PURPLE is where air is fed into each side of the stove into the box tube. There will be adjustable dampers here to adjust and completely disable the secondary burn tubes for all night burns as well as experimentation. Now the Q's

1. I see Warner was headed in the direction of a modern secondary burn stove with a baffle plate, secondary air stream through upper part of door, and preheating of both primary and secondary air in the door. Anybody know how effective this approach at secondary air/burn is? How does it compare to proper secondary burn tube designs?

2. Think it's worth the extra fab effort of the rearmost 'lower' tube, as opposed to just spreading the four tubes across the flat part of the baffle?

3. Should be the holes in the rear tube face down, or on a 45 degree angle to allow the air to flow directly across them? assume gases/flame are flowing on an angle here.

Yes, I know that installing a proper modern high efficiency stove will pay off in time, but I'm going through a nasty divorce and every dollar is being watched carefully. I can spend on fuel, but not on a new stove despite showing the supporting math. Logic and math don't apply here...

Other thoughts?

Thanks,

-Travis

I've been given an old Warner that's been sitting in storage for the last 20 years. It's a bit rusty so it'll get sand blasted and painted. I'm considering adding secondary burn tubes per the attached pic. The BLUE is box tube down each side of stove. The RED are cross tubes with 3/16" holes every inch or two. The PURPLE is where air is fed into each side of the stove into the box tube. There will be adjustable dampers here to adjust and completely disable the secondary burn tubes for all night burns as well as experimentation. Now the Q's

1. I see Warner was headed in the direction of a modern secondary burn stove with a baffle plate, secondary air stream through upper part of door, and preheating of both primary and secondary air in the door. Anybody know how effective this approach at secondary air/burn is? How does it compare to proper secondary burn tube designs?

2. Think it's worth the extra fab effort of the rearmost 'lower' tube, as opposed to just spreading the four tubes across the flat part of the baffle?

3. Should be the holes in the rear tube face down, or on a 45 degree angle to allow the air to flow directly across them? assume gases/flame are flowing on an angle here.

Yes, I know that installing a proper modern high efficiency stove will pay off in time, but I'm going through a nasty divorce and every dollar is being watched carefully. I can spend on fuel, but not on a new stove despite showing the supporting math. Logic and math don't apply here...

Other thoughts?

Thanks,

-Travis

We'll see ....

We'll see ....