We've owned our house since 1998, the third owner of a 2300 sq. ft story and a half, built by the original owner who had no business being his own general contractor. If he owned a square or a level, he sure didn't know how to use them. And the concept of a header was lost on him. So with this previous history of surprise revelations, we apprehensively tore into the replacement of the original fireplace.

The Heatilator was in dire need of an upgrade. The interior firebrick sheets were cracked and had been patched several times, the fresh air intakes adjustment knobs could barely be moved, and the cheesy 80's tile surround had lost most of its grout. We hadn't used the fireplace in for the last three seasons, as the amount of cold air drafting in coupled with the opening and closing of the front door constantly loading wood made any heat gain a break even proposal at best. Coupled with our ground source heat pump primary heating, our electric bills were killing us on the sub zero days, so we really wanted to get a wood burning source of heat back online. Especially since our house sits on nearly 4 acres of timber. Wood supply is NOT an issue.

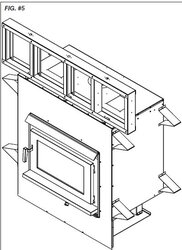

Here is a picture of what we were starting with;

The Heatilator was in dire need of an upgrade. The interior firebrick sheets were cracked and had been patched several times, the fresh air intakes adjustment knobs could barely be moved, and the cheesy 80's tile surround had lost most of its grout. We hadn't used the fireplace in for the last three seasons, as the amount of cold air drafting in coupled with the opening and closing of the front door constantly loading wood made any heat gain a break even proposal at best. Coupled with our ground source heat pump primary heating, our electric bills were killing us on the sub zero days, so we really wanted to get a wood burning source of heat back online. Especially since our house sits on nearly 4 acres of timber. Wood supply is NOT an issue.

Here is a picture of what we were starting with;