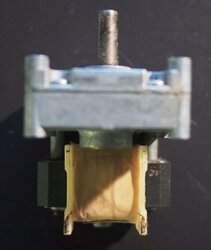

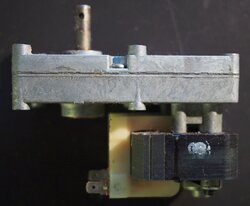

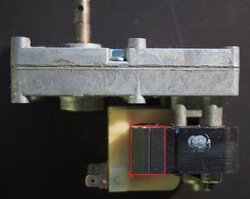

Hi, the auger motor in my 5500M makes a buzzing when the auger moves. The buzz doesn't happen until the stove has been on for about 10 minutes. The buzzing does not occur every time the auger moves, but it does seem to buzz on a regular basis. Sometimes it buzzes for the entire auger turn, sometimes only at the beginning of the turn. I disconnected the motor from the auger, and the motor still makes the buzz occasionally when it turns, so it's not related to the auger. When it's disconnected, the buzz seems to be affected by the angle at which I'm holding the motor. I took apart the motor box.The gears inside look OK, and there is still a lot of grease in there. I didn't see any loose parts or bits in there.

I'd rather not have to spend $170 on a new motor, so if anyone else has any input, I'd appreciate it greatly. TIA!

I'd rather not have to spend $170 on a new motor, so if anyone else has any input, I'd appreciate it greatly. TIA!