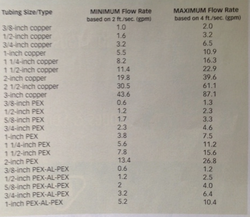

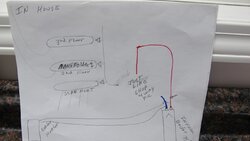

Here is what I have and where I'm at ,a outdoor boiler 75' away from the house , I did step 1 and my target flow rate it comes to 2.50 gpm (30%glycol/24000 btuph) ...on to step 2 , tube size ,I got that covered as I buried 1.25 pex (really it more like 1 1/2 as my uponor fittings of 1.25 "fell in the pex" so much so I had to use uponors 1.50 inch EP fittings)  SO MY question is do I just figure out the piping using just the pipes and fittings "getting it to the house and back" ? This would be step 3 ,sounds easy enough, then Step 4 says to do a head loss calc for each "parallel loop"( p-loop is that each zone in atvalaska speech?is that what they mean?) SO I will/can easily come up with a number for the house to boiler shed , then I need to do each separate "zone?"/or is it a parallel loop? inside the house. and starting from where.....am I reading to much into this ? i need to call somebody

SO MY question is do I just figure out the piping using just the pipes and fittings "getting it to the house and back" ? This would be step 3 ,sounds easy enough, then Step 4 says to do a head loss calc for each "parallel loop"( p-loop is that each zone in atvalaska speech?is that what they mean?) SO I will/can easily come up with a number for the house to boiler shed , then I need to do each separate "zone?"/or is it a parallel loop? inside the house. and starting from where.....am I reading to much into this ? i need to call somebody  !

!

SO MY question is do I just figure out the piping using just the pipes and fittings "getting it to the house and back" ? This would be step 3 ,sounds easy enough, then Step 4 says to do a head loss calc for each "parallel loop"( p-loop is that each zone in atvalaska speech?is that what they mean?) SO I will/can easily come up with a number for the house to boiler shed , then I need to do each separate "zone?"/or is it a parallel loop? inside the house. and starting from where.....am I reading to much into this ? i need to call somebody

SO MY question is do I just figure out the piping using just the pipes and fittings "getting it to the house and back" ? This would be step 3 ,sounds easy enough, then Step 4 says to do a head loss calc for each "parallel loop"( p-loop is that each zone in atvalaska speech?is that what they mean?) SO I will/can easily come up with a number for the house to boiler shed , then I need to do each separate "zone?"/or is it a parallel loop? inside the house. and starting from where.....am I reading to much into this ? i need to call somebody  !

!