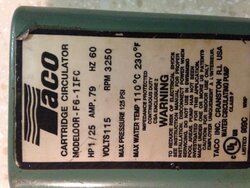

I recently had a taco pump seize up in my system. I put in another used one I had laying around but it sounds to be near the end of its life. This pump feeds water from my garn about 75 ft to the house and then through a plate HX and back. Below is the pump I have had for the last 2 years. I haven't had any issues. I am thinking about getting a variable speed pump that changes speed based on supply and return temp. I can run either 120V or 240V. (240 would require some investment but doable if worth while) Any recommendations or experience on brands/models?

Variable speed pump advise

- Thread starter Robert V

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Karl_northwind

Minister of Fire

That might be a good application for the Taco bumblebee (HEC2). make sure the pump curve is sufficient (it's , and it'll ramp up and down to maintain the stratification in the GARN, and set the delta T at something like 20 degrees, and let'er rip. which speed did you need to have the 00R on to meet the system needs?

Bob Rohr

Minister of Fire

with any ECM you will want to have excellent water quality, any iron ferrite in the system and it will get pulled into those strong ECM magnets.

if you use an ECM circ, I'd highly recommend a magnetic separator, especially with open systems.

if you use an ECM circ, I'd highly recommend a magnetic separator, especially with open systems.

BoiledOver

Minister of Fire

Your system hasn't been online for all that long, has it? Was the pump that failed suited to the system? I see that model has max 15' head and max 12.5 flow. These circs should get years in before failure?

Floydian

Feeling the Heat

with any ECM you will want to have excellent water quality, any iron ferrite in the system and it will get pulled into those strong ECM magnets.

if you use an ECM circ, I'd highly recommend a magnetic separator, especially with open systems.

Very interesting, Bob. I don't recall ever reading of this, either here or at The Wall, though it certainly makes sense.

Without a magnetic separator would it be prudent to do a routine cleaning of the ECM? (In my case an Alpha in a closed, pressurized)

Thanks,

Noah

Oh boy I think I am in a little over my head here. First off I didn't know the pump I had had several speeds! The taco pump that failed has been in service on my garn about 2 years but it was used when I got it. I have never had a lack of heat to the house and the pump always ran quiet but I kind of goofed up when I put my garn in and didn't leave nearly enough room behind it for service so the pump ended up In the hot enclosure rather then outside of it in a cooler area. The motor always felt very hot to the touch but I just assumed that was normal. My goal like Karl mentioned is to maximize stratification and reduce the amount of electricity used. I do send water samples of the garn twice a year and also have a filter on the garn side and the pressure side. I have an ECM circulator in the house for the panel rad system and love it. Below is a rough idea of my set up if that helps. I honestly don't think I need a ton of flow too and from the house but don't want to under/oversize my pump either. I don't mind spending a little money if its worth It in the long run. I had the bumble bee in mind but have no idea if I am in left field or not. Thank you all for your help.

Oh boy I think I am in a little over my head here. First off I didn't know the pump I had had several speeds! The taco pump that failed has been in service on my garn about 2 years but it was used when I got it. I have never had a lack of heat to the house and the pump always ran quiet but I kind of goofed up when I put my garn in and didn't leave nearly enough room behind it for service so the pump ended up In the hot enclosure rather then outside of it in a cooler area. The motor always felt very hot to the touch but I just assumed that was normal. My goal like Karl mentioned is to maximize stratification and reduce the amount of electricity used. I do send water samples of the garn twice a year and also have a filter on the garn side and the pressure side. I have an ECM circulator in the house for the panel rad system and love it. Below is a rough idea of my set up if that helps. I honestly don't think I need a ton of flow too and from the house but don't want to under/oversize my pump either. I don't mind spending a little money if its worth It in the long run. I had the bumble bee in mind but have no idea if I am in left field or not. Thank you all for your help.Forgive my lack of knowledge but what is B&G?Maybe a B&G.........They seem to be a little better built than the comparable Taco.....but at the end of the day, who knows..

Bob Rohr

Minister of Fire

And not to blame the circ pumps, then problem is in the fluid, maybe always has been, but putting those powerful magnets in then system made it more of a concern.Very interesting, Bob. I don't recall ever reading of this, either here or at The Wall, though it certainly makes sense.

Without a magnetic separator would it be prudent to do a routine cleaning of the ECM? (In my case an Alpha in a closed, pressurized)

Thanks,

Noah

The pump manufacturers are responding, trying to add technology to protect the rotor.

But with wet rotor circs, the fluid needs to get to those bearing surfaces, as it travels thrunthe center of the shaft, it will bring it's baggage along with it.

Next time you open a pump, scratch any deposits from the impeller or volute, if it sticks to a magnet it could be iron ferrite

Attachments

DBoon

Minister of Fire

Karl_northwind

Minister of Fire

I thought that rig looked familiar.... on a separate topic, you could cut and slide a couple pieces of polyisocyanurate foam behind the boiler and help keep a little more heat there.

a schematic would be helpful, as I'm looking at the photo of the basement plumbing, it looks weird to me... like the make up water looks like it's connected to the non-pressurized side of the system.

EDIT: never mind I found my goof.

karl

a schematic would be helpful, as I'm looking at the photo of the basement plumbing, it looks weird to me... like the make up water looks like it's connected to the non-pressurized side of the system.

EDIT: never mind I found my goof.

karl

Well the only real issue I am having is pumping water too and from the garn to the flat plate HX. The filter for the garn is on the return side but only part of the water is directed through the filter. I pulled the screen in the Y before the pump at the garn and found a bunch of white crap built up in there. I took the screen out for now but found the pump runs no quieter. The pump on it right now is a taco 007. I was having no issues with anything until the pump at the garn took a crap. I then found the new used pump was making more noise then the old pump ever did. I went ahead and ordered a bumblebee so we will see how that works.

maple1

Minister of Fire

Kind of odd two pumps making noise like that. The only time I get noise of any kind is if a little air is working through, or there is a restriction (throttling a valve will usually introduce noise). So I wonder if your HX is dirty? Especially since you mention finding crap in the filter - which I think is between the HX & the return? So crap would have to go through the HX to get to the filter? (If I read right).

Well the original pump never made any noise as far as I know, but just burnt up one day. I took the pump apart and found the cartridge seized. The pump in there now is making a growling noise like a bearing is starting to fail. You are correct maple1. The garn water flows through the screen in the Y, through the pump, through the flat plate HX and then through the filter and back to the garn. There is also an air coil in the barn that runs directly off the garn water. (The red vertical lines in the pic) I open and closed that loop to see if the noise changed but it did not. I do have valves in place to flush the HX so maybe I should do that to be sure. Any other checks I can make?

Karl_northwind

Minister of Fire

We had an issue with white gunk on the strainer on a 1000 I just put in, and we tracked it down to excess water treatment chemical precipitating out. send a sample in and see what mike tells you. we had to drain 200 gallons and replace with clean water, then pumped thru the fill filter for a day to clean up any floaties. so far so good.

k

k

When I first got the garn up and running there was a bunch white cloudy looking stuff in the water. Precision chem just checked the water recently and said I could use another dose of chem but found no major concerns. The white fuzz is gone for the most part (due to the filter I think) So the crap in the screen may have just been in there from the original water. Long story short, I flushed the HX but found nothing major. I put in the bumblebee tonight and it runs quiet as a church mouse! BUT I think I got stung !! The screen keeps showing an error coded E02 when I attempt to put it in delta T mode. I swap the sensors and found the error code switched to E03. So looks like my brand new pump has a bad temp sensor. I will give taco a call tomorrow.

!! The screen keeps showing an error coded E02 when I attempt to put it in delta T mode. I swap the sensors and found the error code switched to E03. So looks like my brand new pump has a bad temp sensor. I will give taco a call tomorrow.

!! The screen keeps showing an error coded E02 when I attempt to put it in delta T mode. I swap the sensors and found the error code switched to E03. So looks like my brand new pump has a bad temp sensor. I will give taco a call tomorrow.

!! The screen keeps showing an error coded E02 when I attempt to put it in delta T mode. I swap the sensors and found the error code switched to E03. So looks like my brand new pump has a bad temp sensor. I will give taco a call tomorrow.Got a new BB from Supply house and it is working great. Runs at 11 Watts most of the time. Such a cool little pump!

Bob Rohr

Minister of Fire

Is there any static pressure on a circ pump connected to a Garn? Are they open or semi open systems? Most circ pumps need some static head to help prevent cavitation, and the required pressure goes up as the water temperature goes up.

Also keep an eye on any flow restricting valves or devices on the suction side, those too can induce cavitation. Service any filters or strainers regularly. When multiple pumps fail, often there is an application error.

I know a common failure of pumps on open OWF is caused by the the very low pressure and high operating temperatures, often around 212F

Also keep an eye on any flow restricting valves or devices on the suction side, those too can induce cavitation. Service any filters or strainers regularly. When multiple pumps fail, often there is an application error.

I know a common failure of pumps on open OWF is caused by the the very low pressure and high operating temperatures, often around 212F

velvetfoot

Minister of Fire

BB? or B&G?

I like my little B&G Varios. They're not auto, but their speed can be changed in infinite steps with a dial, and they are very quiet.

Here are some pics when I took one apart when I first got them:

https://www.hearth.com/talk/threads/ordered-a-couple-varios.127093/

Edit: Ooops. I see now BB is Taco.

I like my little B&G Varios. They're not auto, but their speed can be changed in infinite steps with a dial, and they are very quiet.

Here are some pics when I took one apart when I first got them:

https://www.hearth.com/talk/threads/ordered-a-couple-varios.127093/

Edit: Ooops. I see now BB is Taco.

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 51

- Views

- 5K

- Replies

- 36

- Views

- 5K

- Replies

- 2

- Views

- 3K