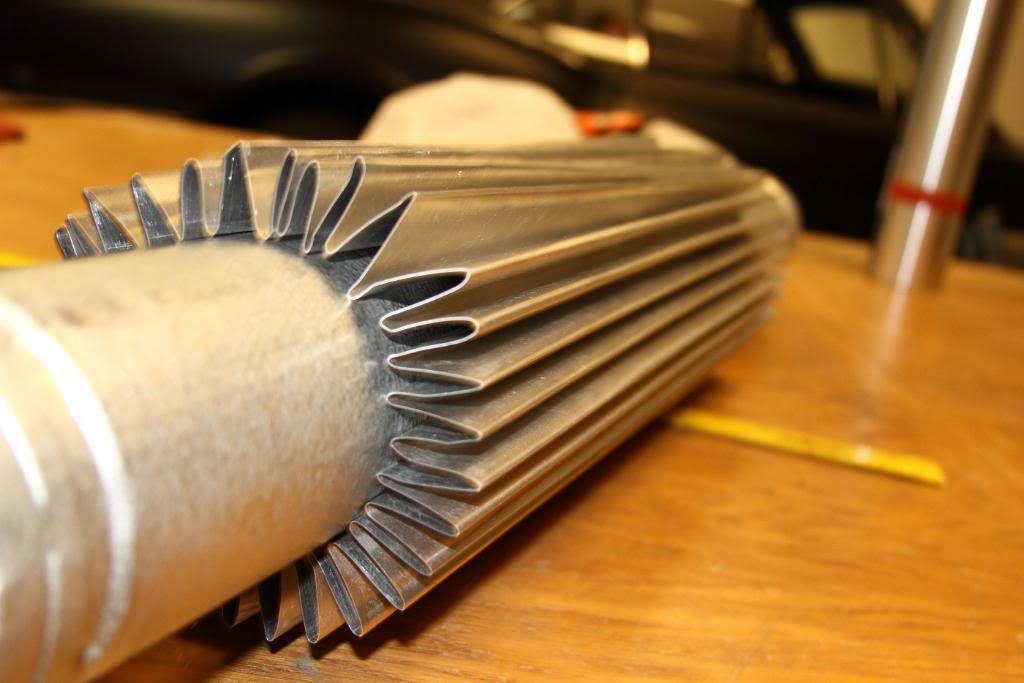

Is there such a thing? I was thinking of building a air to air heat exchanger around my vent pipe, or maybe I already spent the afternoon starting to build one? Please give me one good reason to stop other than it wont work! The only thing I can think of, and maybe the reason you don't see them anywhere is because you could possible cool the pipe down too much and lose your draft? In my head it should work though I can just turn the vent blower up a little. Gonna make it out of Aluminum and put a 650cfm axial fan in it (its already ordered damn it!!). I was actually thinking of making a water to air exchanger and running a open loop system but the I thought the investment would be too much if it didn't work.

Maybe it will save me a couple bags of pellets a week, or am I just crazy. I can't leave stuff alone!!

Maybe it will save me a couple bags of pellets a week, or am I just crazy. I can't leave stuff alone!!