Anybody familiar with this? It is not Vermont Castings but Vermont Stove Company. It is a Shelburne insert with Shelburne and 1981 cast into the back of the fire box. It appears to have a secondary air system and some of that casting is burned out. I'd be surprised if there are any parts for this out there. It's been buried in the corner of my garage for years. I don't know if there's any hope for it or maybe it's destined for the scrap pile.

Vermont Stove Company, Shelburne Insert

- Thread starter harryfatcat

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The very little info I've found by googleing it leads back here. Too bad, it looks like it was a nice stove at one time. Scrap heap, here it comes!

Here is one of my best attempts at an overnight burn. I think I will damper it down to "smoke dragon" status in hopes of having some of this ~30 lb (ash I think) knot left over in the morning. Usually I can't expect more than cinders and ashes after 4 hours. So we will see what I have in the Shelburne after about 6.

wenger7446

Feeling the Heat

How did you do with your overnight burn? How is the stove hooked up?

Much better than expected. That knot rocks! Here it is over six hours later.

^^ after opening doors and cleaning up a bit. Note low temp on door thermometer because it was open.

It appears the temperature controlled air inlet opened itself up as the temps cooled, keeping a light flame coming out of that knot.

Man, that knot was unsplitable and just sitting next to my pile and I wasn't sure I'd be able to fit it, let alone on top of a huge bed of coals.

Very happy!

The boiler did kick on though.

It was just nice to come downstairs to that loud fan and see it actually was doing something.

Edit:

That sweet knot didn't fall to cinders until about 10 AM this morning. 10 hours of burn over 300 degrees on a single knot of wood. Whoo hoo!

Last edited:

How did you do with your overnight burn? How is the stove hooked up?

Slammer install on a 40 foot tall 13x13 mostly interior chimney (very strong draft). It required some sheet metal to direct stove outlet back because the outlet overlaps with the lintel bricks somewhat.

Last edited by a moderator:

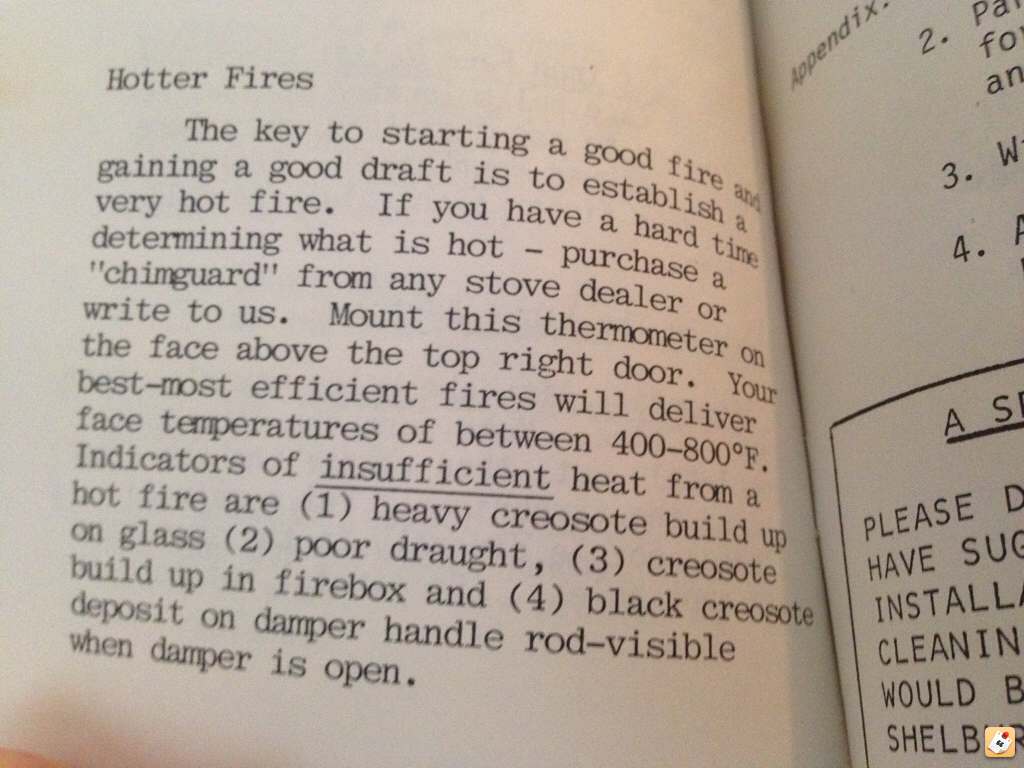

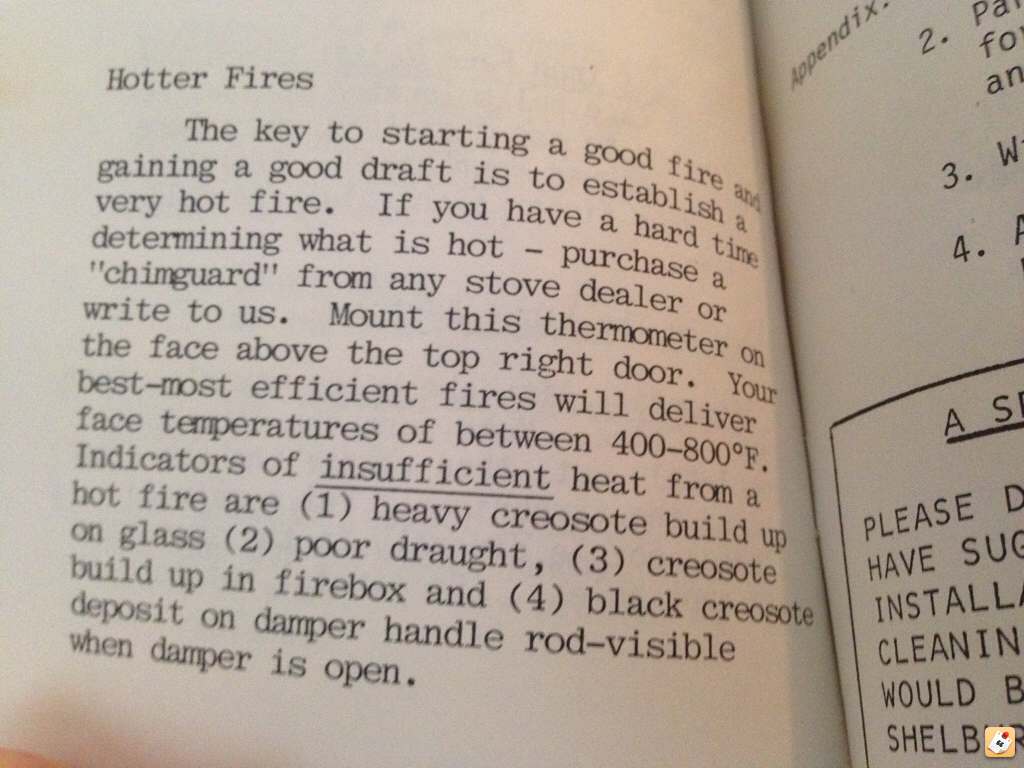

One other thing... This stove likes it hot. I've never achieved over 700 face temps, aside from maybe on the glass.

I have thermometers mounted in both corners where recommended and I barely ever get then to 700 degrees.

I reload, reload, reload, even when I've got so many coals that they spill out the door when I open it.

I was initially searching for "when to reload?" But figured it should be based on temperature. Since a good fire for me is 500 degrees on those readings, I guess I should reload any time the temp falls under 400.

I have thermometers mounted in both corners where recommended and I barely ever get then to 700 degrees.

I reload, reload, reload, even when I've got so many coals that they spill out the door when I open it.

I was initially searching for "when to reload?" But figured it should be based on temperature. Since a good fire for me is 500 degrees on those readings, I guess I should reload any time the temp falls under 400.

And one for sale on DC CL.

http://washingtondc.craigslist.org/nva/for/4214047831.html

It looks like it is in great shape and only $350 asking.

http://washingtondc.craigslist.org/nva/for/4214047831.html

It looks like it is in great shape and only $350 asking.

Thanks BeGreen. Someone contacted me about the manual last night, and i assume your response is also a response to their inquiry.

I wonder if that is the scan of my manual. I have a PDF loaded on my personal web site if that link ever disappears.

If anyone stumbles across this that has any information on a good quite replacement blower, please let me know. Mine is running Ok but I'd like to get a backup or quieter one, maybe a more powerful one???

And if anyone is really hard up for parts, I have an extra complete stove. I've been trying to get my brother to install it in his house, but with the slow progress on that I should probably help a stranger in need if they are out of luck.

I wonder if that is the scan of my manual. I have a PDF loaded on my personal web site if that link ever disappears.

If anyone stumbles across this that has any information on a good quite replacement blower, please let me know. Mine is running Ok but I'd like to get a backup or quieter one, maybe a more powerful one???

And if anyone is really hard up for parts, I have an extra complete stove. I've been trying to get my brother to install it in his house, but with the slow progress on that I should probably help a stranger in need if they are out of luck.

I downloaded the manual from your site and posted it here. Somehow the link got into the report system instead of this thread. I posted it to the wiki to help future inquirers.

Yesterday I walked down the steps into the living room and heard the cheap middle magnetic thermometer fall off the stove door onto the hearth tile. After literally almost a minute I looked at the reading and it was still saying over 700 degrees. The top two corner thermometers were reading only around 500 or 550 and I'm pretty confident I've had those much hotter. I put on my leather glove and picked up the door thermometer when it fell to about 600 and was cooling rapidly. The reading instantly went up to almost 800. The manual says to shoot for temps between 400 and 800 on the top corner thermometers. The fire was putting out so much heat that I nearly burnt my hand on the screen I keep in front if the insert, almost a foot away.

I turned the thermostatic inlet damper "thermostat" down until the inlet closed, but the stove didn't seem to flinch. I turned the fan speed up to noisy-as-all-hell setting to make sure the over-temp shutoff on the fan didn't stop it. I can't remember, but I wonder if that is why I thought the fan died those other times. Perhaps just over temp.

Anyway, it's neat when the fire gets so got that the magnet stops working. It's nice to have a heavy cast stove that can handle those temps without fear too.

95% of the time I run it, I'm just trying to keep it hot with the doors shut and the top exhaust damper all the way closed (forcing exhaust through the afterburners).

I'm ready for the snow. It looks like I've burnt well over a cord so far this year, and will probably do another half this week where it won't break freezing for the next 7 days with the exception of 36 forecasted for Saturday.

Burning hot and happy! Love to occasionally run as an open fireplace too.

I turned the thermostatic inlet damper "thermostat" down until the inlet closed, but the stove didn't seem to flinch. I turned the fan speed up to noisy-as-all-hell setting to make sure the over-temp shutoff on the fan didn't stop it. I can't remember, but I wonder if that is why I thought the fan died those other times. Perhaps just over temp.

Anyway, it's neat when the fire gets so got that the magnet stops working. It's nice to have a heavy cast stove that can handle those temps without fear too.

95% of the time I run it, I'm just trying to keep it hot with the doors shut and the top exhaust damper all the way closed (forcing exhaust through the afterburners).

I'm ready for the snow. It looks like I've burnt well over a cord so far this year, and will probably do another half this week where it won't break freezing for the next 7 days with the exception of 36 forecasted for Saturday.

Burning hot and happy! Love to occasionally run as an open fireplace too.

Shelburne82

New Member

Hi mnowaczyk, I just bought a Shelburne a couple of weeks ago. I really like it! I was reading your thread and thought you may have had a similar issue with your insert. Our fan keeps shutting off. It comes back on after awhile. So after a few times, I pulled it out and took the fan off. Took it apart and cleaned it up "real nice like". After reinstalling the fan and insert it still keeps shutting off. Once the heat cools down the fan can be turned back on. Is this what you have noticed with your fan? Do you think I'm running it to hot? " I'm getting a thermometer today"

Possibly running hot. I thought my fan died but apparently there's a thermo protector on the fan. Does your fan have the external little fan to help keep it cool? Does it run well, or might the fan overheat itself due to some resistance? I have found that removing the rheostat and plugging the fan directly into the wall allows it to run more reliably when all I care about is keeping the blower going. Mine seems to have its loud struggling time, and then sometimes it quiets itself down. I haven't figured it out yet, but I do know the manual references a thermo protector. My occurrences of the fan stopping are very rare now. Thermometers in both top corners are mandatory in my opinion, and the smaller style is the only thing that I think fits there. I put the larger junky one in the middle of the doors. All seem to work well and you can see varying temps on each side of the insert. The manual says to aim for 400-800 F in these corners.

I got this model (Vermont wood stove co. shelburne insert) and am restoring it, new blower, insulation etc, does any one know if the original insulation was asbestos? the stuff was falling of the sides and back from water that went down the chimney and was all over the place, kind of worried me....do I need a hazmat team?

Thanks!, that's a relief, I thought I was a goner!....and me quit smoking 15 yrs ago and got all healthy n' stuff, so if before 1981 it was outlawed, then what is this stuff?,its a tan pressed particle & looks mineral short fiber based and has flecks that sparkle a little in the light, a mica based board maybe? the board turned to a powder when it got wet... so I am using ceramic 1" fire board and "kolwool" blanketing to replace it, trying to get real efficient as this unit will be my only heat outside portable electric and I found pieces that are used in the stove somehow to change it for soft coal operations, including a un-vented ash door and 2 comb like bars, but the manual mentions nothing about installing or using the parts for a coal operation, any ideas?

minn.matts

New Member

I have this stove and I need a new blower. Went to Grainger and all of there fans blow in the wrong direction. Can I get a blower for this stove?

minn.matts

New Member

Shelburn1981

New Member

I run one of these and I need to replace a burned out secondary combustion chamber, the cast piece that hangs in the back. Any one have a parts stove with that part?

Shelburn1981

New Member

Not cracked, the centre points burned away so I am not sure the afterburner is working that well.

Similar threads

- Replies

- 3

- Views

- 679

- Replies

- 4

- Views

- 893

- Replies

- 8

- Views

- 1K