Here it is!

I'm firing up the backyard aluminum foundry for the first time!

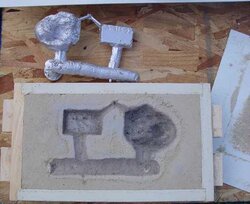

The wooden things on the ground are molds - the stainless bowl has a little experiment I am trying in "lost foam" casting.....

Another pic shows the molds after casting - you can see the excess metal - it goes in one vent and then comes out the other.

Most soon with the results - I already have learned a few things.....

I'm firing up the backyard aluminum foundry for the first time!

The wooden things on the ground are molds - the stainless bowl has a little experiment I am trying in "lost foam" casting.....

Another pic shows the molds after casting - you can see the excess metal - it goes in one vent and then comes out the other.

Most soon with the results - I already have learned a few things.....