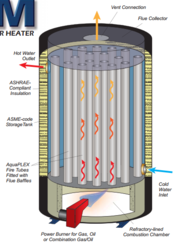

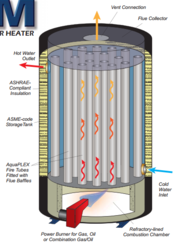

So, at work they just replaced a 125 gallon, gas fired water heater. I was able to grab the old one before it got hauled off for scrap and plan to use it to replace a smaller storage tank I have. There's nothing wrong with the tank, it was just causing rusty looking water (may be caused by the tank or may be from steel pipes upstream). Looking at it's design, however, got me thinking about the possibility to use it as a boiler. I believe it is constructed as shown in the image below, with the burner being installed in a ~6" diameter tube near the bottom. What I was thinking is that I could construct a downdraft fire box that would then connect to this tube. Obviously one of the biggest concerns is not having the ability to easily access the fire/flue tubes for cleaning. (perhaps these can be accessed from below, but it wasn't apparent.)

Last edited: