First Post here. Question for all that are putting in water storage, any considerations to be made regarding the weight of water storage on a concrete basement floor? Going to be building a new house and if placing tanks to hold 500-1000 gallons is something to think about I would get that in the foundation plan.

Water storage load on concrete basement floor?

- Thread starter natemth

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Most 4"-6" residential slabs poured correctly and on sufficient subgrade would handle avg tank stationary loads.

If vertical tanks are being utilized, then the usage of steel "spreader" plates is an option(I did).

If existing slab is deemed insufficient, pouring a reinforced concrete pad(4") may be required.

If new slab(in case mentioned here), additional reinforcement and better subgrade at localized area of tanks would be easy and cheap.

Just plan accurately.

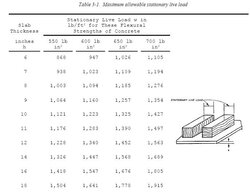

See attached table for some data.

Scott

If vertical tanks are being utilized, then the usage of steel "spreader" plates is an option(I did).

If existing slab is deemed insufficient, pouring a reinforced concrete pad(4") may be required.

If new slab(in case mentioned here), additional reinforcement and better subgrade at localized area of tanks would be easy and cheap.

Just plan accurately.

See attached table for some data.

Scott

Attachments

huffdawg

Minister of Fire

I have 2 vertical 500 gal propane tanks ,each one welded to a 22" truck rim. They are sitting on 4 to 6 " of concrete with 1/4 " rebar grid in the pour. The slab itself was poured over 2 high density foam . Underneath that I have 3' of pit run that I compacted every 6 to 8" then 4" of sand on top of that leveled out nice and flat. Not even a crack so far (knock on wood)!

Huff

Huff

Good then I wasn't thinking I would be overbuilding this. Probably will pour it like I will for the footings under both the girder columns and under the chimney and then I won't have to worry about it. Thanks

711mhw

Feeling the Heat

natemth said:Good then I wasn't thinking I would be overbuilding this. Probably will pour it like I will for the footings under both the girder columns and under the chimney and then I won't have to worry about it. Thanks

Perfect. You might throw a couple of #4 bars 3-4' long in just incase your sub grade is not what you think it is. (about $20).

NP ALASKA

Burning Hunk

I am curious, how thick of spread plate would you use?

I am installing 3 tanks, 2-500 gallon propane tanks stacked with saddle configuration and 1-250 gallon propane tank mounted vertically. They will be centrally located together. I was thinking of a 1/2 steel plate for them to sit on and distribute the weight. Is this thick enough? One would be 9' long and 40" wide. The other would be roughly 45" by 45".

Any thoughts??

Garage floor 4-6 inches? Didnt build it, but I know the guy that did. He said 4" for sure and probably closer to 6" on the outside edges.

I am installing 3 tanks, 2-500 gallon propane tanks stacked with saddle configuration and 1-250 gallon propane tank mounted vertically. They will be centrally located together. I was thinking of a 1/2 steel plate for them to sit on and distribute the weight. Is this thick enough? One would be 9' long and 40" wide. The other would be roughly 45" by 45".

Any thoughts??

Garage floor 4-6 inches? Didnt build it, but I know the guy that did. He said 4" for sure and probably closer to 6" on the outside edges.

ewdudley

Minister of Fire

I am curious, how thick of spread plate would you use?

I am installing 3 tanks, 2-500 gallon propane tanks stacked with saddle configuration and 1-250 gallon propane tank mounted vertically. They will be centrally located together. I was thinking of a 1/2 steel plate for them to sit on and distribute the weight. Is this thick enough? One would be 9' long and 40" wide. The other would be roughly 45" by 45".

Any thoughts??

Garage floor 4-6 inches? Didnt build it, but I know the guy that did. He said 4" for sure and probably closer to 6" on the outside edges.

Half inch plate? Holy overkill, Bat Man.

I wouldn't worry about it whatsoever. Two five hundred gallon tanks ain't jack, you could set them on a sheet of three quarter inch plywood out on the lawn.

Concrete is very strong in compression and would have to be quite thin or would need to have very poor material underneath it to create a problem, with or without re-bar.

I've seen plenty of one to four thousand gallon bulk milk tanks over the years that set directly on random milkhouse floors supported only by four, six, or eight posts with little quarter inch thick pads a couple inches square.

--ewd

Fred61

Minister of Fire

If I were building a new home at this time it wouldn't have enough heat loss to warrent the smallest wood boiler made.

Build a home that doesn't need that amount of heat input. Take advantage of the sun and the super insulated building designs available.

Do alot of homework!

Build a home that doesn't need that amount of heat input. Take advantage of the sun and the super insulated building designs available.

Do alot of homework!

I am curious, how thick of spread plate would you use?

I am installing 3 tanks, 2-500 gallon propane tanks stacked with saddle configuration and 1-250 gallon propane tank mounted vertically. They will be centrally located together. I was thinking of a 1/2 steel plate for them to sit on and distribute the weight. Is this thick enough? One would be 9' long and 40" wide. The other would be roughly 45" by 45".

Any thoughts??

Garage floor 4-6 inches? Didnt build it, but I know the guy that did. He said 4" for sure and probably closer to 6" on the outside edges.

1/2" steel plate is way too excessive, I used 1/8".

Scott

NP ALASKA

Burning Hunk

Thanks for all the input.

Not sure which way I go, I have always been the guy that builds things to with stand an earth quake. Whihc we have pretty regular here in Alaska.

Thanks

Not sure which way I go, I have always been the guy that builds things to with stand an earth quake. Whihc we have pretty regular here in Alaska.

Thanks

Thanks for all the input.

Not sure which way I go, I have always been the guy that builds things to with stand an earth quake. Whihc we have pretty regular here in Alaska.

Thanks

If you truly have seismic considerations and you need restraints put on, then contact me if you need some seismic bracing details, and material lists.

Regarding "overbuilding" for safety factors, I am with you....sometimes it may only help in sleeping better at nights...but hey.. I'll take that.

Good luck man.

Scott

If I were building a new home at this time it wouldn't have enough heat loss to warrent the smallest wood boiler made.

Build a home that doesn't need that amount of heat input. Take advantage of the sun and the super insulated building designs available.

Do alot of homework!

Sure there are things that could be done differently from what I'm going to do but they can come at a much greater cost. Say you could get spray foam insulation and not have next to no infiltration and a R value as high as you can get, but the price.... forget about it.

My quick heat loss calcution for the house (that doesn't do a good job with dealing with any concrete that's above grade) is 45,000 btus at peak for the 2000sq ft home. And this doesn't include the garage or dhw. So say 70k btu's at peak for a quick estimate.

I think a wood boiler is a nice fit for all that. Probably even the 40 size from eko or vigas over the 25

woodsmaster

Minister of Fire

I think a 40kw boiler would probably be to big for a 2000 sq' house unless you have some storage to heat. I'll

bet a 25Kw would be a better fit. I Know my boiler is oversized a lot for my heat load, but I have

storage and wanted the longer fire box. I also wanted to be able to add on to the house and maybe the shop.

bet a 25Kw would be a better fit. I Know my boiler is oversized a lot for my heat load, but I have

storage and wanted the longer fire box. I also wanted to be able to add on to the house and maybe the shop.

NP ALASKA

Burning Hunk

I actually have been planning for this type of situation. I have woke up to shakes and found my dresser dancing across the floor before.

My thought was to use pallet racking and anchor that with unistrut to the wall. Adding feet to metal spread plate and anchor the tanks to it, while anchoring it to the floor.

Your thoughts?

My thought was to use pallet racking and anchor that with unistrut to the wall. Adding feet to metal spread plate and anchor the tanks to it, while anchoring it to the floor.

Your thoughts?

I think a 40kw boiler would probably be to big for a 2000 sq' house unless you have some storage to heat. I'll

bet a 25Kw would be a better fit. I Know my boiler is oversized a lot for my heat load, but I have

storage and wanted the longer fire box. I also wanted to be able to add on to the house and maybe the shop.

Just did another quick and dirty heat loss calc for the garage would be in the neighborhood of 15000 btu's at peak (trying to maintain 50 on 0 degree day), 672 sqft plus the dhw and 500gals of storage.

I actually have been planning for this type of situation. I have woke up to shakes and found my dresser dancing across the floor before.

My thought was to use pallet racking and anchor that with unistrut to the wall. Adding feet to metal spread plate and anchor the tanks to it, while anchoring it to the floor.

Your thoughts?

Weld 4 L brackets to bottom ring of tanks, then bolt through to floor, and then use some longitudinal bracing(do you have a poured wall adjacent?) for sway.

Scott

NP ALASKA

Burning Hunk

The wall is not poured but it is 12 inches, double wall construction. I am hoping just secureing it to wall to prevent tip overs as best it can is acceptable. If things get much worse than that Im moving out anyhow. HAHA

- Status

- Not open for further replies.

Similar threads

- Replies

- 24

- Views

- 1K

- Replies

- 10

- Views

- 2K

- Replies

- 0

- Views

- 447

- Replies

- 8

- Views

- 1K