I noticed the skip - Your weather has to be very different from ours in Indiana -- a skip in heating would have resulted in exploded pipes. What was your outside temp?

1st

Your whole setup is non-trivial- and I don't expect color graphs on my account. I was attempting to explain the reason for my confusion and making light, but I think your setup is second to none.

But, as long as your paying me any mind an outside temp thermistor would be handy. LOL

Are they glass therms u r using??

The reason for the graph questions is I plan on starting a whole new living space heating and cooling system at a new location within the next 60 days. Currently I am getting my ducks in a row. One of my favorite resources is your nofossil.org. You along with some others have inspired me to put together my own page chronicling parts/equipment, local strategies, method efficiencies, and control equipment. I hope to appeal to people who don’t have the computer, welding, engineering, or the equipment experience you do. I am guessing that is quite a few of us. I am certain few wood burners have in depth knowledge of the Linux OS, how IO works in general, PHP, Web servers . You’re the first I have seen proof of.

I plan on trying to give back to the online community. What I had in mind was a contribution of software that would be easy for a novice to setup a control system. As you know this is difficult since a system like yours is complicated and has intricate details.

I thought some simple drive image writer and some setup scripts could go along way to making the control aspect of the boiler operation smoother. Moreover, this could be done cheaply, and with a real payback of time, maybe equipment, and wood.

I think in general the control systems are being overlooked – treated as unimportant.

And they may be unimportant for some. But most probably don’t know enough to make the decision.

An example

The new house I am buying has a boiler ran on Nat gas. I ran it 2 days full(zones in demand) out while it was –5 to 15F. The boiler ran at 200F and the return temp was cold (maybe 50 F) to the touch. The boiler (1968) is new to me, but clearly there is a problem. I don’t know how long it has run this way, but I think a 200 dollar investment and 5(max) hrs by the previous owner could have saved’em a bundle. Maybe this isn’t a good example because it is clearly not operating correctly -demand was there and the water was overheating. These systems can point out the smaller problems as well.

I’m working on control equipment now. I want to spend most of my time on making sure the logic is correct(not perfect) for my setup and for the others who want to use it.

Testing is difficult since I don't have a gasser yet or the hearth chimney insert. So I am making logic without anything to impose or test on yet. -- soon though

But, your setup is well suited to make observation and predictions on. I know it has helped a great deal already.

Nofossil, I wrote a very long diatribe about this event. However, I think that it almost certainly has to do with EKO's circ and control.

However, I still don't think this type of pattern can be the most effective. And this may warrant “tricking” the EKO.

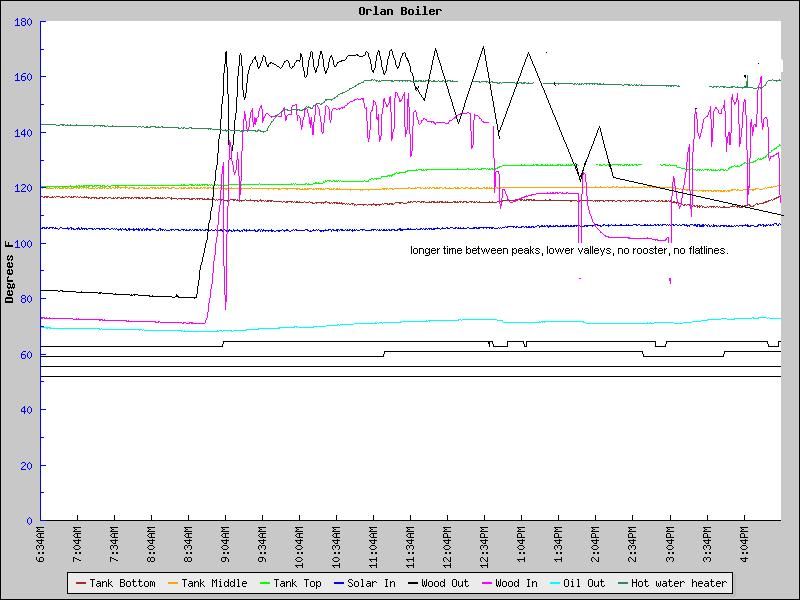

This is what I think it should look like in a perfect world. Note: I don't know/remember how your water return is piped so ignore return temp.

In an attempt to justify why I am even bothering with this question I would explain that this happens at most burns. I admit I can’t quantify or even recognize the events cause. But, When it happens it may cost half split or in some instances maybe a whole split. If that happens 90 times a year you are out the time and energy you put into maybe a face cord. Not a problem for you, but maybe for the other people who pay 230 a face(and some do). And, I don’t want to be the guy who writes the software that costs people 200 a year in extra wood. Furthermore, even if it doesn’t cost money it may cost “tinkering” time for someone else down the road. Maybe if this trend is identified a piece of software can identify it and treat it, after all, every other person who posts is talking about “becoming more efficient with time” Maybe some of the software can identify some of the short-comings and shorten the learning curve.

This isn't limited to gasification. I think a control board for standard combustion boilers, stoves and fireplaces could give many useful pieces of information as well. Circuits that show both o2 and absolute pressure i.e. draft measurements, maintenance requirements, and could email you the “need to know stuff.” -- Like your pipes are about to freeze. Come home quick. – a ways off though

Promise to keep all my posts shorter than this. But Eric as a graph voyeur I am sure you got an eyeful.

Bill