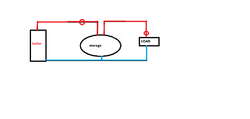

This is very similar to the simplest design but has all the water pass through the tank. The problem I found with the simplest design is that when the load was calling, no heat would transfer to the tank and on cold days, storage would not charge at all. With this design, the hot water flows into the tank and gets sucked right back to the load when the load is calling for heat. Now you do get some heat loss but its not near as bad as I thought it would be. If its a cold tank at the start of the burn, My load may see 130-140 deg water initially but it rises quickly as the tank heats up. If the load is not calling, then I get a full transfer of heat to storage just like the simplest design. The highest I can get storage on a cold day when there is always a call for heat on one zone or another is 170 deg at the top of the tank. My Econoburn 150 gasify's continusly until storage is charged using this design. What you you think?

What do you think of this design?

- Thread starter eriesigtau

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Living in PA, I can't imagine it being that cold that you can't get storage above 170F, even on cold days. I can get mine up to 195F even when its -20F outside, just takes a little longer thats all.

With the SSD, a bypass that goes directly to the loads is used so that you get hot water instantly in your house. If your tank is cold and all the supply water is being sent to the tank first it is being mixed to some extent and it will take more time to satisfy the house needs. You can do it the way you have it drawn tho, not really that big a deal for the most part.

The bigger quesstion/problem I see here is why you are unable to get the tank hotter?

Pat

With the SSD, a bypass that goes directly to the loads is used so that you get hot water instantly in your house. If your tank is cold and all the supply water is being sent to the tank first it is being mixed to some extent and it will take more time to satisfy the house needs. You can do it the way you have it drawn tho, not really that big a deal for the most part.

The bigger quesstion/problem I see here is why you are unable to get the tank hotter?

Pat

SmokeEater

Feeling the Heat

Eriesigtau: We have something in common. . I'm just now plumbing up my pellet boiler to a tank such as in your design with the heat load in the same manner. I'm also connecting a back-up oil boiler to the same tank, both boilers independent of one another. The pellet boiler will operate on its own aquastat that will control the temp of the heated water sent to the tank. The oil boiler will do the same except it will only fire up if the tank's temp drops below a preset. The load will operate on its own controls that will operate the large single pump (delta T) that can vary the delivered output. The tank will contain potable water so I'm pulling the Btus out with a plate HX.

goosegunner

Minister of Fire

My tank is piped like the simple storage. I can heat without problem but I am considering changing to more of a hydraulic separator piping similar to your drawing. I would have the returns separate though. I have issues with gurgling when my load pump kicks in. I think the hydraulic separator method would keep the boiler and load as two independent systems.

Gg

Gg

huffdawg

Minister of Fire

woodsmaster

Minister of Fire

I dony see why it goes in the tank twice. Why not have a T at the top of the tank with one outlet going to tank and one to the load?

ewdudley

Minister of Fire

I have 5 zones in my house and 3 of them are radient floor. It seems as though one of those is always running when outside temps are lesss than 15deg outside. Thats why I'm experimenting with this design. So far so good.

If you can't get extra heat into your storage tank and your boiler is not idling much then perhaps your load is high enough that there just isn't enough heat left over to go into storage.

How many loads (how many pounds of dry wood) are you firing per day? Burning continuously?

If you can't get the storage heated up on the coldest days while firing continuously without idling then you might need a larger boiler.

Or simply be glad it isn't a lot colder.

How many loads (how many pounds of dry wood) are you firing per day? Burning continuously?

If you can't get the storage heated up on the coldest days while firing continuously without idling then you might need a larger boiler.

Or simply be glad it isn't a lot colder.

When plumbed like the simplest... the load pulls all the water to the manfold when any of the zones are on. Boiler size is not an issue because it idles too much when plumbed like the simplest. Not sure how many lbs of wood I burn a day. I might fill the the Econoburn 2x a day at the most when very cold with seasoned split oak/maple. I'm going to to try the simplest again tonight (Its in the 30's today). The way mine is piped, I can alternate between the two designs with the turn of a couple valves and control changes.

ewdudley

Minister of Fire

eriesigtau said:When plumbed like the simplest... the load pulls all the water to the manfold when any of the zones are on. Boiler size is not an issue because it idles too much when plumbed like the simplest.

With either scheme there is nothing to prevent the boiler from sending max output towards the tank. Unless there's something you're not telling us, the boiler can't idle more one way than the other. Hydraulically the two circuit systems are very nearly identical.

I have 5 circ's in the load manafold. I also have the two circs in the diagram. I will have to admit that I just started experimenting with these two designs a few days ago. The system I had before wasn't working at all so a made a change that made it possible to do either of these designs.

Tonight I put the system back to the "simplest" design and adjusted my manafold circs to low speed as well as the circ that pumps into the manafold. The circ at the boiler which is bigger I set to medium speed. I think I'm getting better results so far because storage is charging. I'll let you know what my storage temp gets up to later tonight.

Tonight I put the system back to the "simplest" design and adjusted my manafold circs to low speed as well as the circ that pumps into the manafold. The circ at the boiler which is bigger I set to medium speed. I think I'm getting better results so far because storage is charging. I'll let you know what my storage temp gets up to later tonight.

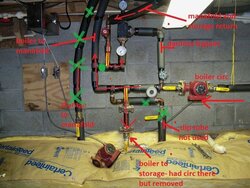

Ok, boiler shut down without storage at full charge (simplest design). house is calling for heat currently and I dont think anothing is going to storage. top of tank is 150deg. Look at the piping and see if you see an error. I drew in the water route as it should flow. the only thing you cant see is the boiler and the pipe going from the bottom of storage to the return line which is tee'd in right above the shop light.

Attachments

The house stopped calling for heat and now its gassing like crazy. I think Ive come to the conclusion that when the house calls for heat, there is so much flow to and from the manafold that the storage in a way gets bypassed. I don't like that close proximity tee to the left and down from the danfoss. I built it that way for support. Maybe that is not working right or maybe the first theory? I guess I would have built this alot differently if I knew what I know now but unfortunatly a guy that had never designed for storage told me how to build this. Now it would be a headache to change it. grrr

maple1

Minister of Fire

I might be out to lunch, but looking at that pic, I'm visualizing the 'storage to manifold' pipe on lower left flowing the other way (down), with all your supply water going up the 'boiler to manifold' pipe, and none down the 'boiler to storage' pipe. In other words, the only water going thru your storage is (cool) return water - and not a good flow, as I'm also visualizing water going round in circles in your manifold loop and danfoss loop.

That is without seeing your manifold setup though, and my system is nowhere like that so I might be missing stuff.

I thought a Danfoss used 3 hookups - I'm only seeing 2 there?

(Edit: you posted again while I was typing...)

That is without seeing your manifold setup though, and my system is nowhere like that so I might be missing stuff.

I thought a Danfoss used 3 hookups - I'm only seeing 2 there?

(Edit: you posted again while I was typing...)

maple1

Minister of Fire

Here's my thoughts (if this works):

Only two lines to the manifold, supply & return. Make the return where I drew the green line, into the dip tube. Do away with the other one marked pointing up in your diagram. Do away with all the danfoss stuff inside the three red lines I drew - put the danfoss loop right at the boiler instead. I'm not seeing how that danfoss loop is doing what it is supposed to be doing.

BUT (huge disclaimer), I am still learning this stuff and have not been thru this exercise myself yet. Would like to see more input to add to the learning.

Only two lines to the manifold, supply & return. Make the return where I drew the green line, into the dip tube. Do away with the other one marked pointing up in your diagram. Do away with all the danfoss stuff inside the three red lines I drew - put the danfoss loop right at the boiler instead. I'm not seeing how that danfoss loop is doing what it is supposed to be doing.

BUT (huge disclaimer), I am still learning this stuff and have not been thru this exercise myself yet. Would like to see more input to add to the learning.

Maple, You cant see the return to the boiler because its hidden but its above the danfoss so there is three hookups. The storage to manafold pipe can only flow towards the manafold because there is a check valve built into the circ at the manafold. Same thing with boiler to manafold. (there are 2 circs at the manafold but only one runs at a given time- i know, its stupid). Ive been beating my head off the wall ever since this system was installed. I should probably just suck it up and start repiping that mess on top of the tank.

maple1

Minister of Fire

Oh, OK, I studied that thing for minutes - couldn't pick it out. That might wreck my last 2 posts.

EDIT (again): After thinking about that for a few more minutes, I still think I'd try doing all of what I said, and just have one return back to the boiler - out the bottom of the tank.

Past my bedtime....

EDIT (again): After thinking about that for a few more minutes, I still think I'd try doing all of what I said, and just have one return back to the boiler - out the bottom of the tank.

Past my bedtime....

here is my idea. Do you think this will work? Eliminate the "storage to manfold" pipe. Then remove the close proximity tee which I show in green. I'm going to have to drain alot to do this but I think its my best bet. Ill also have to put a wire from the ceiling to hold the return part up once I cut the tee out. id really like to move the danfoss to the boiler but it works just fine the way it is (i think, haha).

Attachments

maple1

Minister of Fire

OK, one more before I call it a night.

In this setup I see a direct path from your coldest water (the bottom of your tank) to the inlet on your boiler, that can bypass the danfoss all together. I don't think that is good. With no call for heat, I think either that is the way the flow will go, or it will run thru the danfoss loop (I'm not sure on the flow directions thru that) and bypass the storage all together - with maybe some mixing but it will be on the wrong side of the danfoss (at the T on the way back to the boiler).

How deep is your diptube?

In this setup I see a direct path from your coldest water (the bottom of your tank) to the inlet on your boiler, that can bypass the danfoss all together. I don't think that is good. With no call for heat, I think either that is the way the flow will go, or it will run thru the danfoss loop (I'm not sure on the flow directions thru that) and bypass the storage all together - with maybe some mixing but it will be on the wrong side of the danfoss (at the T on the way back to the boiler).

How deep is your diptube?

maple1

Minister of Fire

OK, I really need to hit the hay. This internet thing has cost me more sleep....

So:

If you can draw from the bottom of your tank thru your dip tube, and close the pipe out the bottom of your tank with a valve, would this make sense? It would put all your water thru the danfoss and leave it where it is. All return goes to tank. If you can understand the crayon work...

EDIT: Na, that won't work, because it won't draw from storage when the fire goes out. Well, it will, but it will return to almost the same place it will draw from. Maybe your last one with the pipe out the bottom of the tank shut off?

OK, goodnight...

So:

If you can draw from the bottom of your tank thru your dip tube, and close the pipe out the bottom of your tank with a valve, would this make sense? It would put all your water thru the danfoss and leave it where it is. All return goes to tank. If you can understand the crayon work...

EDIT: Na, that won't work, because it won't draw from storage when the fire goes out. Well, it will, but it will return to almost the same place it will draw from. Maybe your last one with the pipe out the bottom of the tank shut off?

OK, goodnight...

in hot water

New Member

The problems are #1 it is impossible to know how much flow is going where, and when. #2 when the load pumps and not the boiler pump run you will be running some, maybe a lot of heat from the tank thru the boiler and up the flue to the great outdoors. But since energy can neither be created or destroyed it will come back to grow more trees and firewood some day

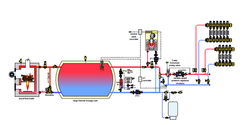

Turn it into a hydro separator with 4 completely separator connections. You could also install a 3 way zone valve and bypass the storage to go directly to the load to save warm up time if you are not going to maintain the tank temperature.

This drawing is a bit more complex with a mod con boiler input. It also shows mixing with outdoor reset to max out the tank drawdown.

hr

Turn it into a hydro separator with 4 completely separator connections. You could also install a 3 way zone valve and bypass the storage to go directly to the load to save warm up time if you are not going to maintain the tank temperature.

This drawing is a bit more complex with a mod con boiler input. It also shows mixing with outdoor reset to max out the tank drawdown.

hr

Attachments

Maple, If I shut the valve off from the bottom of the tank to the return line, then there is no outlet out of the tank. It took me a while to go to sleep last night because pipes were spinning in my head, lol. I'm going to brainstorm more when Im home from work.

maple1

Minister of Fire

Thanks for keeping me up half the night - had this stuff bouncing around in my head even when I did get to sleep. lol.

After all that, and before I try another drawing edit, I'll try the concise effort. How deep is your dip tube? If you can't draw all your tank return flow out of that, I think you will need to draw it all out of the bottom and move your danfoss to your boiler. For starters.

After all that, and before I try another drawing edit, I'll try the concise effort. How deep is your dip tube? If you can't draw all your tank return flow out of that, I think you will need to draw it all out of the bottom and move your danfoss to your boiler. For starters.

dip tube is 1" copper and turns 45 deg to the right. It should be about 6in from the bottom. The outlet at the bottom has a 4" nipple sticking into the tank to prevent sediment from entering the system. That line runs up and tee's into the boiler retun/danfoss line. the tee is right about the shop light.

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 438

- Replies

- 8

- Views

- 604

- Replies

- 7

- Views

- 1K

- Replies

- 0

- Views

- 953