maple1

Minister of Fire

Trying to come up with something to try with minimal rebuilding.

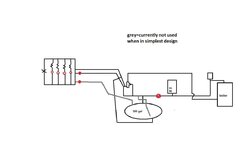

Almost the same as your last one, except T the bottom of the danfoss/load return, to the dip tube. And close the valve at the bottom of your tank so there is only one way back to the boiler - thru the danfoss. That should allow flow thru the dip tube to reverse when your boiler circ stops running & your zones are calling for heat (draw from storage when the fire goes out), but would likely still allow some flow thru the cool boiler when doing that though. How much flow will go where I have not much idea.

All that is dependant on the 1" dip tube being able to handle all the flow though. If not, I think you should return to the boiler from the bottom of the tank & move the danfoss to the boiler as mentioned before.

Still looking forward to seeing more input from others.