Is there really a need or advantage to testing water with a closed pressurized system? How much, aside from cleaning ashes out & making sure your boiler return temp is where it is supposed to be, is there to do to maintain a wood boiler to get longer life out of it?

It depends on what fluid you put in the system to begin with and how well it was cleaned and flushed out.

If the system has a lot of copper that was soldered you should flush out the flux residue or it will taint the water. Oils and pipe dope, assembly fluids and greases should all be flushed out. It's a good idea to use a hydronic cleaner, at least some TSP or dishwasher soap to cut the oil and grease, flux etc.

If the system was cleaned and good quality water added, no leaks, then the fluid should be safe for many years.

Avoid water that is hard, high TDS, high chlorides. Many boiler manufacturers now indicate the water quality and levels for those.

Keeping O2 out of the system is very important. Always use a barrier pex on hydronic system. We are still dealing with the early PB, and non barrier rubber tube systems that sludge up and destroy non ferrous components.

The type of test and readings you get depend on what is in the system to begin with. Hydronic glycols will be in the 10- 11 ph range. If the drop to the 7 range it's time to replace them or re-buffer them. Different hydronic conditioners will have specific test kits to assure that they are still in good condition.

I'd stay away from hard water over 10- 12 grains, it will precipitate out the hardness on your boiler surfaces and need an aggressive chemical to clean. This is the same as with instantanous type water heaters, with new water added daily the hardness will coat the HX surfaces.

Ideally the system would be filled with DI or DM deionized or demineralized water. You can rent the equipment to attach to your water supply to filter you boiler fill water. It looks like a small water softener tank, but does not back wash. After so many gallons run through the tank is returned and re-bedded. Culligan has DI equipment available if you have a large system to fill. I take a 55 gallon plastic barrel to their location and they fill it with DI water for me. It's cheap insurance if your jobsite water is hard, rusty, sulphery, cloudy, etc.

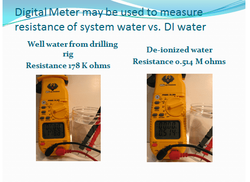

Chemicals can be added to correct bad fill water, but it's best to start with good fill water. A simple ph strip or pencil tester is a good tool to check fluid conditions.

A slide from a recent water quality seminar presented by GEO installer and troubleshooter Jeff Persons in Ohio, used by permission