So after looking at a dizzying array of diagrams and reading countless theories & methods I am still stumped as to how best to plumb my Eko 60 in an efficient and cost-effective manner for my system.

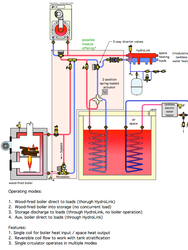

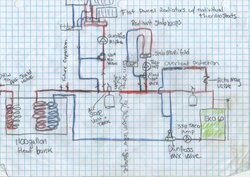

My loads are going to be a flat panel radiator zone, two separate one loop slab zones, and the storage tank. I really only want to use one coil in the storage tank to charge it and draw heat back off for the loads when the boiler isn't being fired. I'm pretty sure I saw this diagram mapped out somewhere here, but can't find it any more.

SO back to my question.... do I charge the storage tank and then draw off for the load, or can I hit the loads off of the boiler & charge the tank at the same time and....???? Or am I stressing over nothing because I have 20 projects up in the air, winter is closing in & I'm behind the 8-ball on everything and I don't want to wake up to find the dog dish frozen to the kitchen floor again.......

My loads are going to be a flat panel radiator zone, two separate one loop slab zones, and the storage tank. I really only want to use one coil in the storage tank to charge it and draw heat back off for the loads when the boiler isn't being fired. I'm pretty sure I saw this diagram mapped out somewhere here, but can't find it any more.

SO back to my question.... do I charge the storage tank and then draw off for the load, or can I hit the loads off of the boiler & charge the tank at the same time and....???? Or am I stressing over nothing because I have 20 projects up in the air, winter is closing in & I'm behind the 8-ball on everything and I don't want to wake up to find the dog dish frozen to the kitchen floor again.......