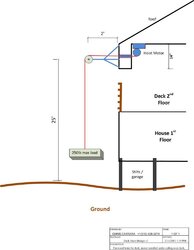

Any "hoist geniuses out there? I need a hoist installed on the top of my deck pictured below. I will need to go down about 25', and carry about 250 lbs of wood. The motor will need to be attached to the ceiling on the inside of the deck, while the cable goes straight out horizontally about 2' (to keep the wood sack away from side of house on way up) and then around a pulley and down. The pulley will need to be on a bracket that sticks out off the side of house just above deck.

What do ya think? I'll supply the parts required, the beer, some cash, and a hot stove! . You supply the know how!

. You supply the know how!

What do ya think? I'll supply the parts required, the beer, some cash, and a hot stove!

. You supply the know how!

. You supply the know how!

Last edited by a moderator: