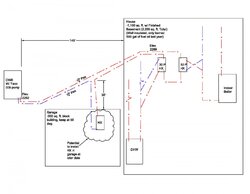

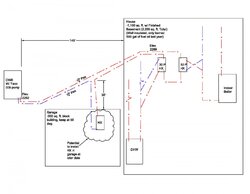

I was recently given an outdoor furnace by a family member. It is a 1996 Central Boiler model SB 17. It is still in good shape with no leaks, so I have decided to try to get a few more years out of it. I am trying to heat a 2,200 sq. ft. house (total including finished basement) and my DHW. My house apparently is well insulated as I only burned 500 gallons of fuel oil each of the past two winters that I have been in this house, including last winter which had several weeks of sub-zero temps. I also plan on running the return line through my garage for the potential to add a heat source there in the future. I am only hoping to be able to heat the garage to about 50 deg. or so. After a lot of head scratching and reading post on this and many other forums on how to hook it up, I have finally came up with the plan that is shown in the attached picture.

So hear are my questions:

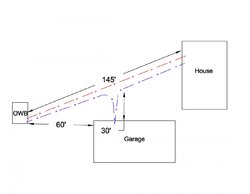

-Is heating the garage a pipe dream with this boiler? It only adds about 30' feet of trench to run the return into the garage, is it worth it?

-Is there a benefit to using 1 1/4" lines, or should I save the money and install 1" lines? I believe the Taco 009 pump only pumps 8 gallons a minute. I am considering using 1 1/4" lines in case the current pump is not enough then I can upgrade to a larger pump and the lines will already be in place. Does that make sense?

-Do you think the current pump is large enough?

-Any other advice or suggestions? (just an FYI, I do plan on spray foaming the lines in place like shown in this forum)

So hear are my questions:

-Is heating the garage a pipe dream with this boiler? It only adds about 30' feet of trench to run the return into the garage, is it worth it?

-Is there a benefit to using 1 1/4" lines, or should I save the money and install 1" lines? I believe the Taco 009 pump only pumps 8 gallons a minute. I am considering using 1 1/4" lines in case the current pump is not enough then I can upgrade to a larger pump and the lines will already be in place. Does that make sense?

-Do you think the current pump is large enough?

-Any other advice or suggestions? (just an FYI, I do plan on spray foaming the lines in place like shown in this forum)