keyman512us

Member

HOLD THE PHONE !

!

This is exactly what you want/need and I can "walk you right through the installation" Eric:

http://cgi.ebay.com/Air-Products-MR...ryZ42897QQrdZ1QQssPageNameZWD1VQQcmdZViewItem

At $17 and some change...I might be buying one or two myself

I would go with this particular relay (for a variety of technical reasons I will not even begin to describe...so as not to confuse you or anyone else following the thread.)

...Some folks "in heating circles" might say "Just throw in a pony relay and be done with it".

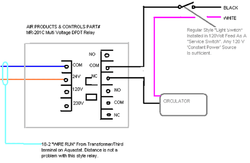

Not quite that easy. A 'pony relay' is a set of "wet contacts"(in terms of how it actuates...it has it's own power supply built in)...The 201 is a "dryset" and of minimal power consumption. How low??? When I first started trying to figure out the best way to wire my system I experimented with powering a 201...off the T-T terminals... on the Oil Primary control of the oil burner, and it worked. The 201 would "power up" but not draw enough power to close T-T on the oil primary... not bad when you stop and think about it!

!

!This is exactly what you want/need and I can "walk you right through the installation" Eric:

http://cgi.ebay.com/Air-Products-MR...ryZ42897QQrdZ1QQssPageNameZWD1VQQcmdZViewItem

At $17 and some change...I might be buying one or two myself

I would go with this particular relay (for a variety of technical reasons I will not even begin to describe...so as not to confuse you or anyone else following the thread.)

...Some folks "in heating circles" might say "Just throw in a pony relay and be done with it".

Not quite that easy. A 'pony relay' is a set of "wet contacts"(in terms of how it actuates...it has it's own power supply built in)...The 201 is a "dryset" and of minimal power consumption. How low??? When I first started trying to figure out the best way to wire my system I experimented with powering a 201...off the T-T terminals... on the Oil Primary control of the oil burner, and it worked. The 201 would "power up" but not draw enough power to close T-T on the oil primary... not bad when you stop and think about it!