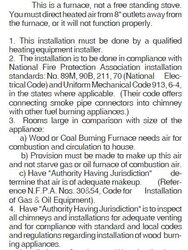

I have a Hotblast 1557M located in the basement of a ranch style home. The house is about 70 feet long and the furnace is in the middle of a long side and vented outside through stainless triple wall pipe. The furnace has dual blowers so I ran duct work about 15 feet out to each side to registers I put in for this setup. It is in the teens outside right now and we would burn up if it weren't for opening some windows. That's not my concern though. I am concerned about how hot the floor registers get and the duct work connected to the floor. There are many times, the registers are so hot, I can't even touch them. This condition happens even if I have the furnace air intake

completely closed off. I may be overly concerned, but could this possibly lead to the floor or carpet catching on fire? Thanks for any help.

completely closed off. I may be overly concerned, but could this possibly lead to the floor or carpet catching on fire? Thanks for any help.