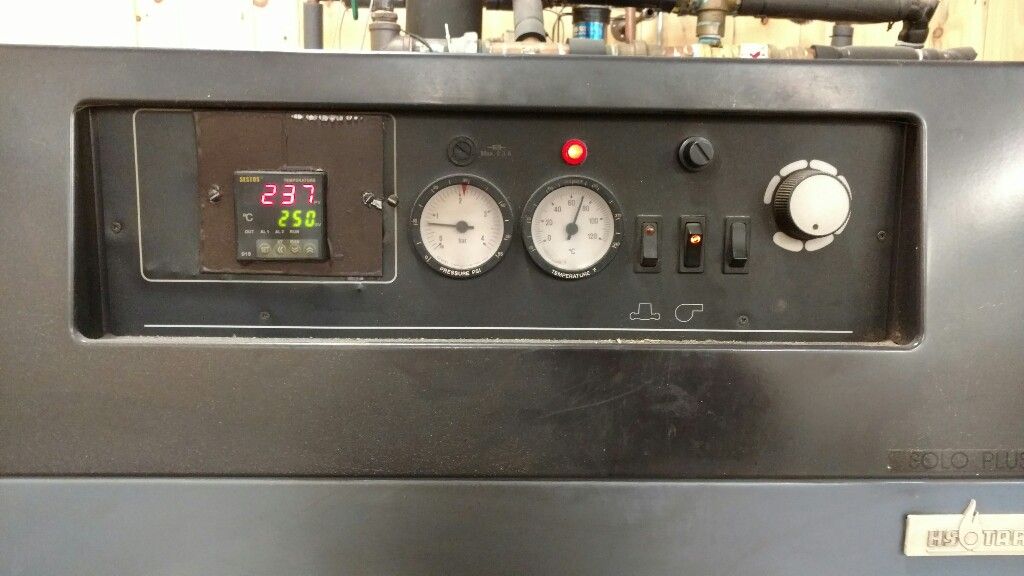

The wood I salvaged after some logging in May 2015, consisting mostly of 1-1/2" to 4" rounds of aspen, ash and birch, is too dry after two summers of seasoning. I had to greatly dampen down the draft fan on my Tarm to keep the stack temperature within a reasonable range. I have a stack temperature controller set to shut the draft fan off at stack temp of 250C (482F) and back on at 245C. It works very well, and the draft fan was cycling consistently today before I re-set the damper to reduce the air input. Not a problem too often experienced.

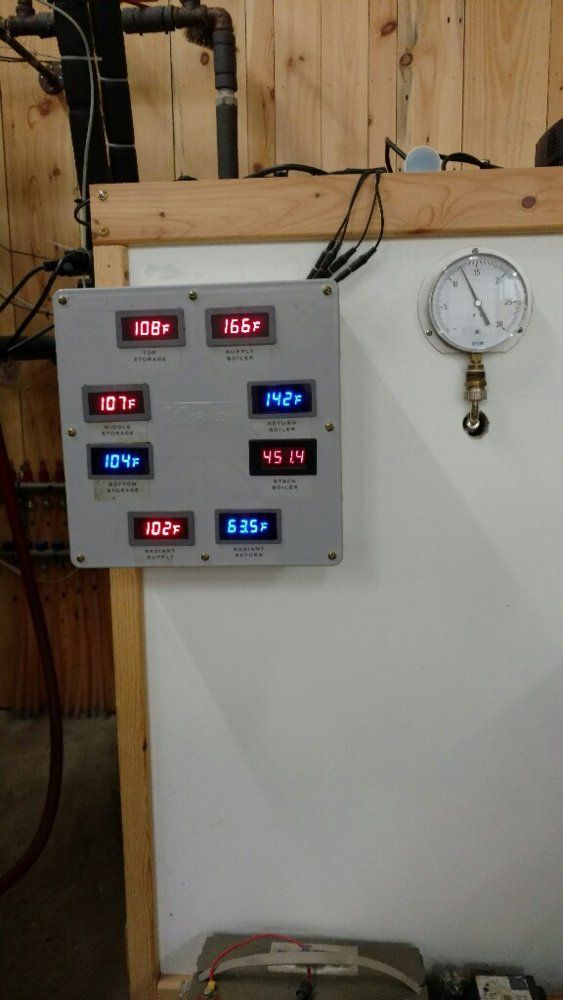

The last firing before today was six days ago (away for a few days for Christmas), and the tank temperature had dropped to 100F. Radiant load at a flow rate of 2.25 gpm was 43,312 btuh.

The last firing before today was six days ago (away for a few days for Christmas), and the tank temperature had dropped to 100F. Radiant load at a flow rate of 2.25 gpm was 43,312 btuh.