The questions:

Do I need to re-pressurize the expansion tank to clear out the air?

Should I close all lines in the slab and run one at a time to clear the air?

The back story:

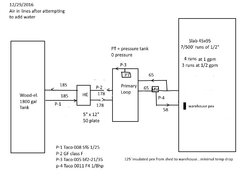

I noticed that the small blue (expansion?) tank read 0 psi...so I hooked up a hose and turned on the water to re-pressurize. The pressure gauge didn't move right away so I went to check on the pump at the Spring and determined I had a leak in the line that I was hooked up to, thus no water pressure.

Came back later to find that I somehow added air to the lines...now no heat to the slab.

Tank is 185...far side of the HE is 178 going to and from the Primary loop (where the expansion tank is).

Far side of the primary loop it's 65 going into the 3 way Mixing valve, 58 to the slab and 65 coming from the slab to the primary and MV.

Pumps all working

I can see air bubbles in the sight vials on each run of pex in the warehouse.

Do I need to re-pressurize the expansion tank to clear out the air?

Should I close all lines in the slab and run one at a time to clear the air?

The back story:

I noticed that the small blue (expansion?) tank read 0 psi...so I hooked up a hose and turned on the water to re-pressurize. The pressure gauge didn't move right away so I went to check on the pump at the Spring and determined I had a leak in the line that I was hooked up to, thus no water pressure.

Came back later to find that I somehow added air to the lines...now no heat to the slab.

Tank is 185...far side of the HE is 178 going to and from the Primary loop (where the expansion tank is).

Far side of the primary loop it's 65 going into the 3 way Mixing valve, 58 to the slab and 65 coming from the slab to the primary and MV.

Pumps all working

I can see air bubbles in the sight vials on each run of pex in the warehouse.