M

mikefrommaine

Guest

Figured I would tap into the brain trust.

Has anyone used an indirect water heater as a heat exchanger for unpressurized storage? I am planning to add storage to my system this summer and for a lot of reasons unpressurized makes more sense.

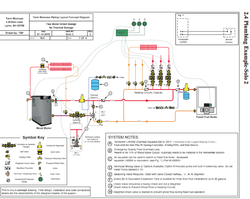

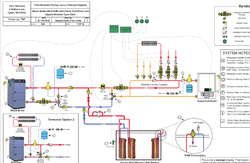

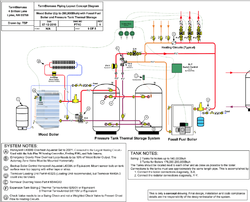

I piped my system using the Tarm diagrams (plumbing example solo - 4) and planned to use "example F" to add my storage. I have purchased most of what I need except for the tank and copper for a heat exchanger.

http://www.woodboilers.com/admin/uploads/public/WoodBoilerPlumbingSchematic1211web.pdf

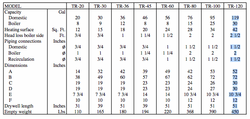

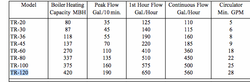

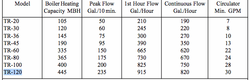

I happen to have two Triangle Tube TR 120's sitting in the basement not being used and started thinking that I could use one for a heat exchanger in place of a copper coil. The unpressurized 500-1000 gallon tank will have to be at least 30-50 feet away from my wood boiler and primary loop. The indirect could be next to the boiler or next to the unpressurized tank -- not sure which would be most efficient.

I know I will need to add another pump to the system to make this work, but I'm not sure how I would control it. Should I let it run 24/7? (doesn't seem efficient) I keep coming up with overly complex solutions in my mind that would equal the cost of just buying the copper. Is there some super efficient pump that could be set to maintain an equal temp between the indirect and bulk tank?

Let me know if you think I'm barking up the wrong tree.

Anyways thanks in advance.

Has anyone used an indirect water heater as a heat exchanger for unpressurized storage? I am planning to add storage to my system this summer and for a lot of reasons unpressurized makes more sense.

I piped my system using the Tarm diagrams (plumbing example solo - 4) and planned to use "example F" to add my storage. I have purchased most of what I need except for the tank and copper for a heat exchanger.

http://www.woodboilers.com/admin/uploads/public/WoodBoilerPlumbingSchematic1211web.pdf

I happen to have two Triangle Tube TR 120's sitting in the basement not being used and started thinking that I could use one for a heat exchanger in place of a copper coil. The unpressurized 500-1000 gallon tank will have to be at least 30-50 feet away from my wood boiler and primary loop. The indirect could be next to the boiler or next to the unpressurized tank -- not sure which would be most efficient.

I know I will need to add another pump to the system to make this work, but I'm not sure how I would control it. Should I let it run 24/7? (doesn't seem efficient) I keep coming up with overly complex solutions in my mind that would equal the cost of just buying the copper. Is there some super efficient pump that could be set to maintain an equal temp between the indirect and bulk tank?

Let me know if you think I'm barking up the wrong tree.

Anyways thanks in advance.