Hello:

I am a newbie wood burner going on 5 years. Mostly, every year I appreciate how little I know. I have most of my wood up which is progress. Although there are other forums to join and ask questions I thought I would stay here and see if someone might be able to counsel me. I am learning.

I have my Husky 372 XP running great and have had some locals get me up to speed on how to make a chain sharp! So, that is my primary tool and I have enjoyed getting to know it more and more. It just runs!

I picked up a Stihl today at a yard sale which advertised a log splitter. Log splitter was too much of a project and if the current owner was not fixing it, I was not going to fix it. On the way home I went

through the high rent district and saw another yard sale. For $10 I figured why not pick up a Stihl.

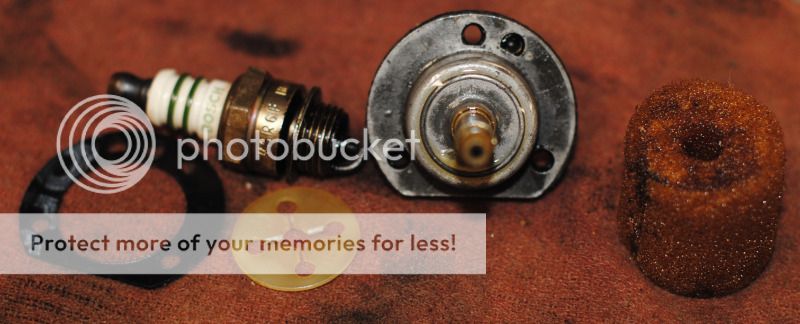

Unlike the Husky which has a stamped model and SN, you can't figure anything out on this Stihl. After hours on other forums I am not much closer. What I did learn is the SN is useless unless the saw was registered at time of purchase. What I gather is helpful is the casting numbers. The recurring number on the castings is 1120.

I got it to run. Runs great for 30 under load and then loses all power. Remove the load and it runs just fine. I figure to trouble shoot the issues I need to figure out what it is. Of course the down side of all this is I could have been splitting or collecting more wood today so it has cost me a day. At times I wonder if I should just stow it and move on. It's not like I need it. Just part of the fun of collecting wood is tinkering with the gear.

I am a newbie wood burner going on 5 years. Mostly, every year I appreciate how little I know. I have most of my wood up which is progress. Although there are other forums to join and ask questions I thought I would stay here and see if someone might be able to counsel me. I am learning.

I have my Husky 372 XP running great and have had some locals get me up to speed on how to make a chain sharp! So, that is my primary tool and I have enjoyed getting to know it more and more. It just runs!

I picked up a Stihl today at a yard sale which advertised a log splitter. Log splitter was too much of a project and if the current owner was not fixing it, I was not going to fix it. On the way home I went

through the high rent district and saw another yard sale. For $10 I figured why not pick up a Stihl.

Unlike the Husky which has a stamped model and SN, you can't figure anything out on this Stihl. After hours on other forums I am not much closer. What I did learn is the SN is useless unless the saw was registered at time of purchase. What I gather is helpful is the casting numbers. The recurring number on the castings is 1120.

I got it to run. Runs great for 30 under load and then loses all power. Remove the load and it runs just fine. I figure to trouble shoot the issues I need to figure out what it is. Of course the down side of all this is I could have been splitting or collecting more wood today so it has cost me a day. At times I wonder if I should just stow it and move on. It's not like I need it. Just part of the fun of collecting wood is tinkering with the gear.