Bob,

How big of a buffer tank do you use for these setups?

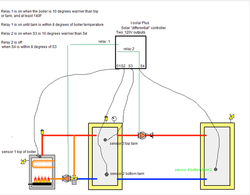

How do you control the exchange of water from main storage as the main storage temps decrease towards the bottom end of usable temp?

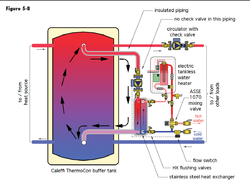

Any size tank will work. I see some of the European set up with a 180L about 50 gallon tank. The more storage capacity the more DHW you can exchange. A 5 minute shower probably runs 10- 15 gallons of hot, depending how much cold I mix. I've seen this 160 gallon tank up to 167°F with five 4X8 collectors. Or it can be heated by the EKO up to 185° or so.

I have taken a shower with the tank down around 110°F. Full hot on the shower valve, but plenty warm. I should be able to get within 8- 10° of the tank temperature at the faucet.

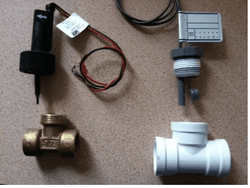

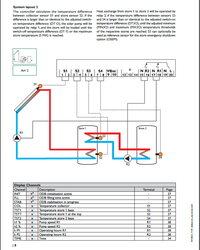

The plate HX design shows

130° tank temperature

120° desired DHW

50° incoming from well

5 gpm flow rate

I know my summertime incoming runs higher than that, but actual use shows these calcs to be very accurate.

The only control mechanism is the flow switch to turn on the HX pump. I don't have a back up installed yet, so I'm the rest of the control, once it starts to run cool, I get out of the shower

I glance at the tank temperature before I try the shower. If it's below 110° I will not get a warm shower. I'm looking at a very small electric tankless, maybe 5-6 KW, with any pre-heat that should provide a shower without a problem.

gg