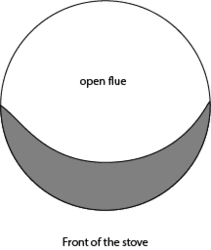

Just (finally) installed my Buck Stove model 85. It has 40' of 6" insulated SS flex for the flue and it drafts real real good. My question is on the the correct air damper settings (it has no flue damper), how far do I choke it down to? 3/4 of the way closed and it still burns quickly through wood with a firebox full of flames, the manual states 1/2 closed for the damper for burning but at 1/2 closed it is burning HOT. How do I go about finding the correct setting to let it cruise at?

My parents have the same stove, but with a 8" SS liner that is only 20' or so and it behaves entirely differently. Any more then 1/2 closed and it will almost kill the fire.

Comments/suggestions/tips?

My parents have the same stove, but with a 8" SS liner that is only 20' or so and it behaves entirely differently. Any more then 1/2 closed and it will almost kill the fire.

Comments/suggestions/tips?