- Oct 3, 2007

- 1,539

The ongoing saga of my basement renovation continues....I'm getting close to finishing the alcove for the TV which is basically a built in entertainment center flanked by built in bookshelves on either side. It's actually the repurposed framework of a closet the previous owner of my house had built. Here is what the partially finished alcove looks like:

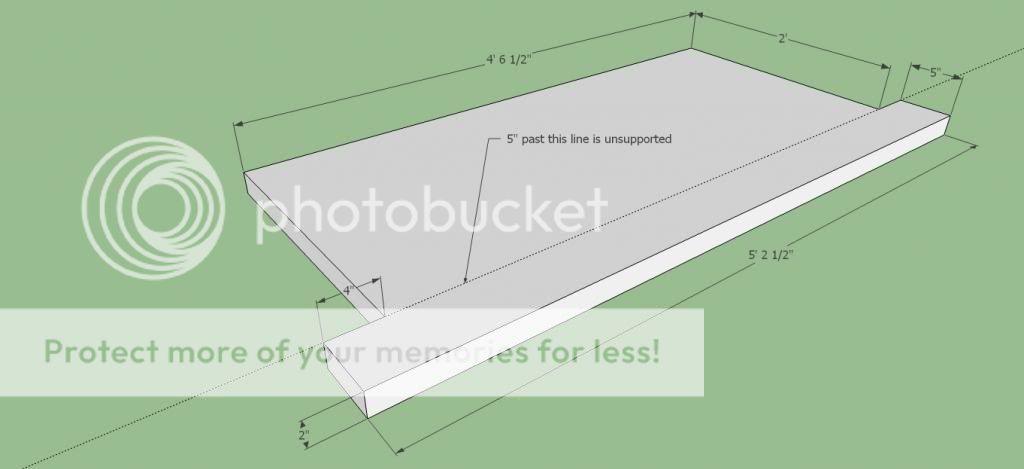

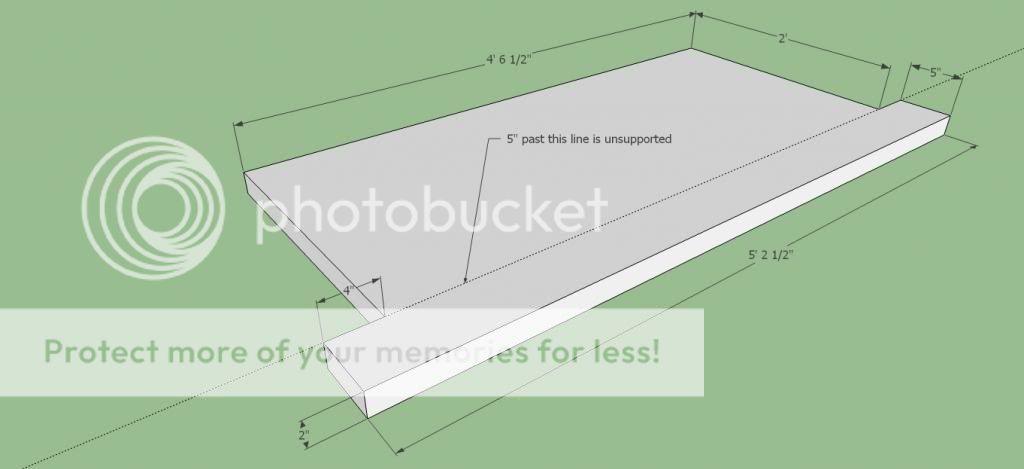

You can see where the TV will hang (the panel on the wall has a receptacle plus a pass through for coaxial, HDMI, ethernet, etc...) and the built in underneath which will house the satellite box and other assorted multimedia gadgetry. The question for me was what kind of surface to put on the topside to finish it. I wanted a kind of "hearth," (how appropriate ) so my first thought was stone, but then I thought about finding the piece, getting it cut, the cost, etc... So I started reading up on concrete countertops. It's something I've thought about doing for a while. One of these days we'd love to redo our kitchen ourselves and concrete counters would be a nice alternative to shelling out big $$$ for granite or some other stone. However, they are not the average DIY project, so I figured this would be good practice. Here is the top I've designed for the basement:

) so my first thought was stone, but then I thought about finding the piece, getting it cut, the cost, etc... So I started reading up on concrete countertops. It's something I've thought about doing for a while. One of these days we'd love to redo our kitchen ourselves and concrete counters would be a nice alternative to shelling out big $$$ for granite or some other stone. However, they are not the average DIY project, so I figured this would be good practice. Here is the top I've designed for the basement:

Last night I bought a 4x8 sheet of melamine faced 3/4" particle board which will be used to make the form along with some other supplies (silicone caulk to seal the form, metal lath and 3/8" rebar for reinforcement). Tonight I'll probably cut out the forms and maybe assemble them-hopefully pouring concrete this weekend! I found out that Quikrete makes a concrete specifically blended for countertops with strengtheners and anti-cracking additives already mixed in so I'm going to order three bags today as it's not an item stocked at my local big-box. I'm curious to hear if anyone else here has tackled concrete counters before?

You can see where the TV will hang (the panel on the wall has a receptacle plus a pass through for coaxial, HDMI, ethernet, etc...) and the built in underneath which will house the satellite box and other assorted multimedia gadgetry. The question for me was what kind of surface to put on the topside to finish it. I wanted a kind of "hearth," (how appropriate

) so my first thought was stone, but then I thought about finding the piece, getting it cut, the cost, etc... So I started reading up on concrete countertops. It's something I've thought about doing for a while. One of these days we'd love to redo our kitchen ourselves and concrete counters would be a nice alternative to shelling out big $$$ for granite or some other stone. However, they are not the average DIY project, so I figured this would be good practice. Here is the top I've designed for the basement:

) so my first thought was stone, but then I thought about finding the piece, getting it cut, the cost, etc... So I started reading up on concrete countertops. It's something I've thought about doing for a while. One of these days we'd love to redo our kitchen ourselves and concrete counters would be a nice alternative to shelling out big $$$ for granite or some other stone. However, they are not the average DIY project, so I figured this would be good practice. Here is the top I've designed for the basement:

Last night I bought a 4x8 sheet of melamine faced 3/4" particle board which will be used to make the form along with some other supplies (silicone caulk to seal the form, metal lath and 3/8" rebar for reinforcement). Tonight I'll probably cut out the forms and maybe assemble them-hopefully pouring concrete this weekend! I found out that Quikrete makes a concrete specifically blended for countertops with strengtheners and anti-cracking additives already mixed in so I'm going to order three bags today as it's not an item stocked at my local big-box. I'm curious to hear if anyone else here has tackled concrete counters before?