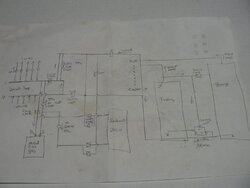

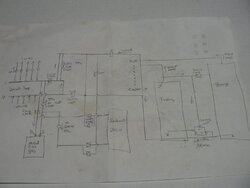

Drawing is very close to my as built but it is closer to my idea of a reference design. I don't know if I will get enough heat passively from the storage as shown but I do know I get enough straight from the Froling supply header, when the Froling is firing. I have a circ there and disabled it, I do not have to pump through, plenty heat rises.

Primary concerns, fast heat from repeated cold starts bypassing storage at startup. Direct isolated, and heat trapped loops do not heat up idle piping. Mod con boiler would have OAT reset and DHW priority call built into the boiler, so, taps directly into the loads. Using OAT reset built in the mod con boiler and bypassing storage increases efficiency, lowers RWT, boiler firing turns down and goes off earlier every firing cycle.

Drawing shows the LK 810 loading unit which will close off flow to the boiler as return temp drop below 150 F or so, reducing boiler standby loss while drawing from storage (but I could redraw it to show the BWRT protection built into the pump controllers).

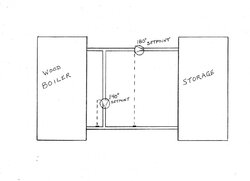

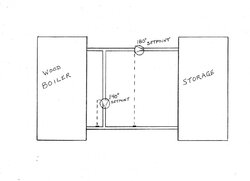

Tried to show a hydraulically separated flow between DHW and storage to maintain stratification, DHW has a high flow and high return water temp while storage would want to come off and return slowly. Since electrical is my thing and not heat, this last part is the one I would like heat engineered (can I take heat from storage slowly and passively as shown?). Indirect over plate and frame because water soluble minerals in the cold water supply, when heated will cause mineral precipitation either in the tank or on the HX plates. Low grade service techs in the future will cut and replace the plate and frame HX rather than clean it, just like they will chop the ECM circs and replace with old style PSC. Codes and reference designs will have to change to make a market in this.

Lastly, This is the only thing I would consider when building new (in cold climates). Found the link in another thread here. Insulated envelope totally surrounding the foundation, Heat that radiantly and there's most of your storage and distribution problems solved, very simply.

http://www.nauglerhouse.com/foundation.html

Fresh drawing in the last hour for your viewing pleasure.