Hello

I am working on a couple stoves that do not have enough vacuum to keep the vacuum switch closed. The stoves are clean and no visible signs of what is wrong.

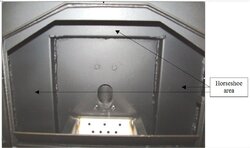

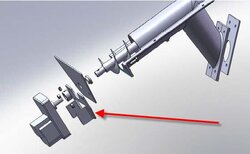

I just learned that Magnum in their product improvements have drilled holes in the back of the firebox behind the ash pan and inserted metal snap in hole caps in newer stoves similar to these.

http://www.grainger.com/Grainger/Hole-Plug-4HFT6?Pid=search

So what about the older BabyCountrySide stoves that are now plugged up after the 3-4 years it takes to plug that area up? Just got some pics of the newer stove with the cleanout cap!

Magnum's new Baby CountrySide manual page 25

BACK ASH CHAMBER AREA: Every 2-4 weeks

Periodically inspect the back ash chambers to make sure that they have not

plugged. Contact your local dealer for the proper cleaning tools. Clean out

any obstruction that would cause the ash to not drop out of the chamber.

There is a clean out plug behind the ash pan that needs to be inspected once

a month.

I am working on a couple stoves that do not have enough vacuum to keep the vacuum switch closed. The stoves are clean and no visible signs of what is wrong.

I just learned that Magnum in their product improvements have drilled holes in the back of the firebox behind the ash pan and inserted metal snap in hole caps in newer stoves similar to these.

http://www.grainger.com/Grainger/Hole-Plug-4HFT6?Pid=search

So what about the older BabyCountrySide stoves that are now plugged up after the 3-4 years it takes to plug that area up? Just got some pics of the newer stove with the cleanout cap!

Magnum's new Baby CountrySide manual page 25

BACK ASH CHAMBER AREA: Every 2-4 weeks

Periodically inspect the back ash chambers to make sure that they have not

plugged. Contact your local dealer for the proper cleaning tools. Clean out

any obstruction that would cause the ash to not drop out of the chamber.

There is a clean out plug behind the ash pan that needs to be inspected once

a month.