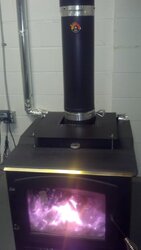

While the fin system extracts heat from the stove using conduction, it releases it using both radiation and convection from hot fins exposed to air.

Defending my comment from 15 mos ago.....when the fins are closely spaced (as in #4), convection dominates.

.

.