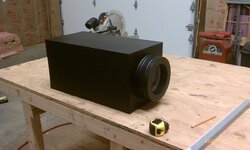

So I have this shed, a pole barn and after much waffling decided to switch insurance companies (after 20 years without a claim) and install a woodstove. The NC30 is the best bang for the buck stove available at this time for a durable, high output, non-cat stove that is even made in america. I measured an actual firebox volume of over 3cf. This stove will be used to burn occasionally at high output and not simmered all day like a house stove. Everything about this stove is heavy duty and I am impressed.

I used all simpson duravent pipe except for the single wall at the stove. The Class A is 9 feet long and the single wall is just under 10 feet. SIngle wall is challenging to work with for me, hard to snap together, the telescoping piece was extremely tight even with wd-40 lube but I got it all in.

My AHJ requires an EPA stove and an 18" tall hearth. I decided to dry stack concrete block for the hearth after seeing large stacks of CMU block used to hold up planting tables at the local home depot. That stack of block is very solid, was cheap, and easy to stack. Of course hitting it with a truck would be a problem but I figure that the stove will just dangle from the three screws in each joint of the single wall chimney pipe right?

Ignore the acetylene, gasoline, and propane tanks in the background. They are an illusion.

This is a permitted install. Inspection will be in the next week or so after I do some more housekeeping.

How do you like my wheelbarrel stove lifting method? I didn't even take the blower and stove legs out of the stove. Two men easily lifted the stove onto the hearth.

I think that smoke detector will have to go.

I used all simpson duravent pipe except for the single wall at the stove. The Class A is 9 feet long and the single wall is just under 10 feet. SIngle wall is challenging to work with for me, hard to snap together, the telescoping piece was extremely tight even with wd-40 lube but I got it all in.

My AHJ requires an EPA stove and an 18" tall hearth. I decided to dry stack concrete block for the hearth after seeing large stacks of CMU block used to hold up planting tables at the local home depot. That stack of block is very solid, was cheap, and easy to stack. Of course hitting it with a truck would be a problem but I figure that the stove will just dangle from the three screws in each joint of the single wall chimney pipe right?

Ignore the acetylene, gasoline, and propane tanks in the background. They are an illusion.

This is a permitted install. Inspection will be in the next week or so after I do some more housekeeping.

How do you like my wheelbarrel stove lifting method? I didn't even take the blower and stove legs out of the stove. Two men easily lifted the stove onto the hearth.

I think that smoke detector will have to go.

Last edited by a moderator: