Anybody else remember this guy? He came on here saying how great masonary heaters were and he was going to build one in a house that he was building. I thought he had even started getting some supplies and then nothing. Was curious if he ever followed through.

ByQ masonry heater?

- Thread starter smithm1979

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I've been PMing with him a bit since I am very interested in building a masonry heater for next year. I think some of you scared him off.

I'm a bit more practical. I'd be building on a solid cement slab and having a centerpiece in the room is the goal. I also think that loading a fire twice a day and forgetting it is a great way to go. I'm babysitting more than I would like to currently. Masonry heaters are not so easy to retrofit in most homes at a reasonable cost. Also, I've seen photos of many that are just plain 'butt ugly' but also some that are absolutely stunning. Obviously, they are not for everyone.

I also have a few of the best masonry heater experts within an hour's drive. You can have them do everything, have them just do the refractory part and you finish it off, you can buy a kit for the refractory section and DIY, or you can buy plans and do everything yourself. You can also do a masonry chimney through the roof or go to the ceiling and then use SS chimney. Obviously, the cost can go from less than a decent wood stove with chimney to 'skys the limit'.

Any particular questions or just curious? I can add links if you are interested.

I'm a bit more practical. I'd be building on a solid cement slab and having a centerpiece in the room is the goal. I also think that loading a fire twice a day and forgetting it is a great way to go. I'm babysitting more than I would like to currently. Masonry heaters are not so easy to retrofit in most homes at a reasonable cost. Also, I've seen photos of many that are just plain 'butt ugly' but also some that are absolutely stunning. Obviously, they are not for everyone.

I also have a few of the best masonry heater experts within an hour's drive. You can have them do everything, have them just do the refractory part and you finish it off, you can buy a kit for the refractory section and DIY, or you can buy plans and do everything yourself. You can also do a masonry chimney through the roof or go to the ceiling and then use SS chimney. Obviously, the cost can go from less than a decent wood stove with chimney to 'skys the limit'.

Any particular questions or just curious? I can add links if you are interested.

Just curious really. I hope it's working out for him but I personally thought he seemed to think everything about it would be relatively easy, that he would be able to build it by watching a few YouTube videos. I just can't imagine myself trying to build one without an expert, but I don't know his level of expertise. Thanks for the update.

Actually, if you can lay blocks according to plans, it is pretty easy. He did send me a link to one site that has some excellent photos of a guy who built one from plans and it turned out great. Not too keen on the choice of outer bricks he used but it's his house, not mine. The link also has some great info on solar arrays, building off grid, building with field stone, etc. Well worth the time in reading his blog. I have forwarded this site to other people who I know are interested. Nothing like seeing photos of work in progress to help you understand. The link is to the heater part, just click to see the other sections:

http://jaredbarnhart.blogspot.ca/search/label/masonry heater

http://jaredbarnhart.blogspot.ca/search/label/masonry heater

Kosmik

Member

There's a few masons around the US that do them. Also, Canada. Most are in Europe.

Just read one book on them, reading another now.

Probably going to be what I do when I finally buy....

But if I end up renting for a few more years, may just bite the bullet and get a nice stove to move around (as I got a buddys to store wood at, he doesn't know it yet ).

).

What I like is the integrated ovens, sleeping areas, lower radiating temperatures and seemingly ease of use. Build hot fire, refill, refill, burn down, pull damper (could even automate a 'sniffer' for the damper). Also, since you are using hot fires, they make use of some of the less than desirable cuts for most people. The hardest thing would seem to be measuring out the wood loads, so you don't overfire and crack it. Corpicing trees, where possible, may actually provide better fuel and faster regrowth (apparently 'corpicing' or pollarding was very popular in the 'Little Ice Age', when they were most concerned about making the best use of their woodlands).

I think plenty of practice in masonry projects before tackling a masonry stove, would be advised from my readings. In Europe a stove mason may only build masonry stoves (thus accumulating a lifetime of stove building knowledge).

Not saying you couldn't do it, first time without masonry experience. But chances of making minor mistake that turns into a crack, may go up.

But they better be some turn-key plans and parts, because there is a lot of bricks to move should you not put in the right expansion joint develop a leaking crack. Or if you unknowingly use some cement and have to tear into it...You may be spending $$$ on new bricks.

It's not just about it being easy to get the bricks laid... It's did you do it well enough that you don't have to take it apart and rebuild it.

A lot of mass, a lot of heat = a lot to go wrong on the build.

But if they market the plans and materials together, or are very specific on materials...Could be done.

Supporting it is always the first problem. 2 to 12 tons is a lot of weight over a small footprint.

Then there is the plans... The stove can only be as good as the plans. There are differing schools of thought on the design. Which one is best seems to be personal preference... As long as the dimensions and materials are in order, so the masonry absorbs the proper heat before exit, the type of design shouldn't be too much of a concern.

But since some designs were developed over hundreds of years of trial and error... Might want to see if he's copying an existing established design, or being creative? If it is the latter, ask for his credentials in thermo-dynamics.

I'm planning on starting some foray into learning masonry to see if it is feasible to do it myself, or better off hire a qualified mason (w/ experience in builds).

Then there is also the issue 'response'. Many, many issues to address with the heating needs too. You have only so much of a heating range with them, so they need to be sized accordingly, for the house/room.

But instead of turning down airflow and increasing combustion temps or using cats, like the EPA. The N.European countries give the incentives for the building of masonry heaters. They have found them to be safe and efficient, and the numbers/test tend to back that claim up.

Just read one book on them, reading another now.

Probably going to be what I do when I finally buy....

But if I end up renting for a few more years, may just bite the bullet and get a nice stove to move around (as I got a buddys to store wood at, he doesn't know it yet

).

).What I like is the integrated ovens, sleeping areas, lower radiating temperatures and seemingly ease of use. Build hot fire, refill, refill, burn down, pull damper (could even automate a 'sniffer' for the damper). Also, since you are using hot fires, they make use of some of the less than desirable cuts for most people. The hardest thing would seem to be measuring out the wood loads, so you don't overfire and crack it. Corpicing trees, where possible, may actually provide better fuel and faster regrowth (apparently 'corpicing' or pollarding was very popular in the 'Little Ice Age', when they were most concerned about making the best use of their woodlands).

I think plenty of practice in masonry projects before tackling a masonry stove, would be advised from my readings. In Europe a stove mason may only build masonry stoves (thus accumulating a lifetime of stove building knowledge).

Not saying you couldn't do it, first time without masonry experience. But chances of making minor mistake that turns into a crack, may go up.

But they better be some turn-key plans and parts, because there is a lot of bricks to move should you not put in the right expansion joint develop a leaking crack. Or if you unknowingly use some cement and have to tear into it...You may be spending $$$ on new bricks.

It's not just about it being easy to get the bricks laid... It's did you do it well enough that you don't have to take it apart and rebuild it.

A lot of mass, a lot of heat = a lot to go wrong on the build.

But if they market the plans and materials together, or are very specific on materials...Could be done.

Supporting it is always the first problem. 2 to 12 tons is a lot of weight over a small footprint.

Then there is the plans... The stove can only be as good as the plans. There are differing schools of thought on the design. Which one is best seems to be personal preference... As long as the dimensions and materials are in order, so the masonry absorbs the proper heat before exit, the type of design shouldn't be too much of a concern.

But since some designs were developed over hundreds of years of trial and error... Might want to see if he's copying an existing established design, or being creative? If it is the latter, ask for his credentials in thermo-dynamics.

I'm planning on starting some foray into learning masonry to see if it is feasible to do it myself, or better off hire a qualified mason (w/ experience in builds).

Then there is also the issue 'response'. Many, many issues to address with the heating needs too. You have only so much of a heating range with them, so they need to be sized accordingly, for the house/room.

But instead of turning down airflow and increasing combustion temps or using cats, like the EPA. The N.European countries give the incentives for the building of masonry heaters. They have found them to be safe and efficient, and the numbers/test tend to back that claim up.

Kosmik

Member

"We chose to wrap the core of our heater with fiberglass for an expansion/slip joint. Some masons use cardboard but fiberglass seemed more professional to me."

Not sure about that.

The reason some use cardboard is because they want a solid object to ensure their clearance of facing from firebox. Once fired, the cardboard is turned to ash and the gap is maintained. Why else would you put a combustible in wood furnace. Others just trust in their masonry skills to maintain that gap. The fiberglass also would inhibit the flow of heat from the core to the facing, IMO. He probably though, "Jeeze, that brick is going to get hot. Might burn the cardboard if I'm not careful. Better use some fiberglass." And then if someone overfires that sucker, somehow and the fiberglass insulation starts smoking It's a masonry stove. Masonry and air (sometimes steel grates or doors), are all that should be in them.

It's a masonry stove. Masonry and air (sometimes steel grates or doors), are all that should be in them.

Treat building a masonry stove like you would building a DIY EPA stove. You want a firm understanding of the principles involved, even if you are following someone else's design. Then you probably want a little experience with the techniques, before you are in a mission critical situation. Weld fails at mid burn, or for MS, flue chamber caves in during firing schedule (or more likely, lots of hairline cracks bordering structural).

What 'seems more professional', seems to be a bad idea to me.

The real question will be 1, 5, 10 years from now. There are masonry heaters in E.Europe, C.Europe hundreds of years old. Other designs, Korea/China, were rebuilt every-year. Roman Baths were an old form of masonry heating, and radiant floor.

Just finished "The book of masonry stoves: rediscovering and old way of warming"

http://www.amazon.com/The-Book-Masonry-Stoves-Rediscovering/dp/1890132098

Good read.

Next read is "Masonry Heaters: Desinging, building, and living with a peice of the sun"

http://www.amazon.com/Masonry-Heaters-Designing-Building-Living/dp/1603582134

Also I just been getting my hands on all the concrete, masonry and general construction books/info I can from the library and internet.

Lots of good stuff on the internet, people trying to sell you their design. Lots of info as they explain how their stove design is better than the other, pointing out flaws showing dynamics.

Feel free to hit me up, I'm learning, but I may be able to help.

Not sure about that.

The reason some use cardboard is because they want a solid object to ensure their clearance of facing from firebox. Once fired, the cardboard is turned to ash and the gap is maintained. Why else would you put a combustible in wood furnace. Others just trust in their masonry skills to maintain that gap. The fiberglass also would inhibit the flow of heat from the core to the facing, IMO. He probably though, "Jeeze, that brick is going to get hot. Might burn the cardboard if I'm not careful. Better use some fiberglass." And then if someone overfires that sucker, somehow and the fiberglass insulation starts smoking

It's a masonry stove. Masonry and air (sometimes steel grates or doors), are all that should be in them.

It's a masonry stove. Masonry and air (sometimes steel grates or doors), are all that should be in them.Treat building a masonry stove like you would building a DIY EPA stove. You want a firm understanding of the principles involved, even if you are following someone else's design. Then you probably want a little experience with the techniques, before you are in a mission critical situation. Weld fails at mid burn, or for MS, flue chamber caves in during firing schedule (or more likely, lots of hairline cracks bordering structural).

What 'seems more professional', seems to be a bad idea to me.

The real question will be 1, 5, 10 years from now. There are masonry heaters in E.Europe, C.Europe hundreds of years old. Other designs, Korea/China, were rebuilt every-year. Roman Baths were an old form of masonry heating, and radiant floor.

Just finished "The book of masonry stoves: rediscovering and old way of warming"

http://www.amazon.com/The-Book-Masonry-Stoves-Rediscovering/dp/1890132098

Good read.

Next read is "Masonry Heaters: Desinging, building, and living with a peice of the sun"

http://www.amazon.com/Masonry-Heaters-Designing-Building-Living/dp/1603582134

Also I just been getting my hands on all the concrete, masonry and general construction books/info I can from the library and internet.

Lots of good stuff on the internet, people trying to sell you their design. Lots of info as they explain how their stove design is better than the other, pointing out flaws showing dynamics.

Feel free to hit me up, I'm learning, but I may be able to help.

Last edited:

Forgot to mention his use of fibreglass. I think (from the photos) that he was using a stiffer fibreglass board, not bats but hard to tell. Still, you are correct that it does not make any sense in using it to create a gap and to add even a tiny bit of R value between the refractory blocks and the facing is counter productive. I was actually musing on a PM that it might be an advantage to add dry sand in the gap. That way, you have an expansion gap that can expand plus some conduction. That was musing only and I would not do it without serious discussion with an expert. I have not done enough research yet but my philosophy is more toward taking a real hard look at various design options and going with what I see as the best workable solution. That's a fuzzy way of saying I'm not married to tradition but if you are going to mess with it, I want proof that your's is better. I have learned the hard way that there are too many great new ideas that don't work.

The refractory blocks are pretty easy (I still maintain) to build with but agree that it's not something many people could handle. I've built block walls and laid my share of both flagstone and ceramic tiles. Agreed that this is NOT the place to learn. If in doubt, I will opt for having a mason build the thermal section and I do the facing. My problem is that I know I will not find a design that fits with my needs in the space I have, so I may have to modify or have an expert modify for me.

One link that ByQ sent me is the Masonry Heater Assn. and well worth a visit. http://www.mha-net.org/

One guy close to me is here: http://www.stovemaster.com/html_en/home.html

The refractory blocks are pretty easy (I still maintain) to build with but agree that it's not something many people could handle. I've built block walls and laid my share of both flagstone and ceramic tiles. Agreed that this is NOT the place to learn. If in doubt, I will opt for having a mason build the thermal section and I do the facing. My problem is that I know I will not find a design that fits with my needs in the space I have, so I may have to modify or have an expert modify for me.

One link that ByQ sent me is the Masonry Heater Assn. and well worth a visit. http://www.mha-net.org/

One guy close to me is here: http://www.stovemaster.com/html_en/home.html

Kosmik

Member

If cardboard has worked for European masons for ages, I'd stick with that.

Mind you, not all masons put a divider in, or some only do so temporarily, and remove before finishing the top.

Yeah, I seen them both. Stovemaster uses the 'Russian' design, for lack of a better word, versus the conrtaflow, 'Finnish' design, in the blogspot. Seems like he knows what he's doing, following another's design.

If he's close I'd call him. There's a mason near me (<100 mi.) who built one in town for a 'sustainable home', I might have to call him up one day.

The purpose is to have NOTHING but air in that space, so expansion/contraction can work...Don't overthink it. If packing it with sand worked better, you'd see it in the designs. They use plenty of sand in their mortar, so it's on hand, probably was experimented with.

Everyone want's to take something that has worked perfectly well and been refined over hundreds of years, put some math to it and say "Look, I've improved upon what some lowly master stone mason in Europe has done." Mind you the master stone mason probably has a lot more math under his belt than even a 'smart' american, it's just how trade school works over there.

Or they think they're smarter than the Russians? Who have done extensive testing of designs and concepts. (same with other countries.)

Point is, if he had 'followed' his directions with the kit, he would have never wrapped that sucker in fiberglass.

But he 'knew better', and the result is a lot of laughs. And a stove that won't every give him the efficiency that masonry heaters obtain....

Funny how he built it last winter, yet no update after use.

EDIT: What are your design requirements that you find abnormal... In my cursory study of masonry (stone) stoves/ovens, I have found as many unique applications as circumstances. But usually the biggest challenge has been the modern need, "I need it to heat my whole house 3 story, 4,000 sqft." Which has been done, but traditionally they are like woodstoves, meant to heat a room/level, open floor plans. A peasant's house was built around the heating device, when now we have to build the device around the house.

Mind you, not all masons put a divider in, or some only do so temporarily, and remove before finishing the top.

Yeah, I seen them both. Stovemaster uses the 'Russian' design, for lack of a better word, versus the conrtaflow, 'Finnish' design, in the blogspot. Seems like he knows what he's doing, following another's design.

If he's close I'd call him. There's a mason near me (<100 mi.) who built one in town for a 'sustainable home', I might have to call him up one day.

The purpose is to have NOTHING but air in that space, so expansion/contraction can work...Don't overthink it. If packing it with sand worked better, you'd see it in the designs. They use plenty of sand in their mortar, so it's on hand, probably was experimented with.

Everyone want's to take something that has worked perfectly well and been refined over hundreds of years, put some math to it and say "Look, I've improved upon what some lowly master stone mason in Europe has done." Mind you the master stone mason probably has a lot more math under his belt than even a 'smart' american, it's just how trade school works over there.

Or they think they're smarter than the Russians? Who have done extensive testing of designs and concepts. (same with other countries.)

Point is, if he had 'followed' his directions with the kit, he would have never wrapped that sucker in fiberglass.

But he 'knew better', and the result is a lot of laughs. And a stove that won't every give him the efficiency that masonry heaters obtain....

Funny how he built it last winter, yet no update after use.

EDIT: What are your design requirements that you find abnormal... In my cursory study of masonry (stone) stoves/ovens, I have found as many unique applications as circumstances. But usually the biggest challenge has been the modern need, "I need it to heat my whole house 3 story, 4,000 sqft." Which has been done, but traditionally they are like woodstoves, meant to heat a room/level, open floor plans. A peasant's house was built around the heating device, when now we have to build the device around the house.

Last edited:

We have a 30 x 17' wall of windows facing south and there is a 4' gap in the center for a steel support beam. The stove has to fit in that 4' space, which is not a big problem, but I also do not want it sticking out as far as most designs I have seen. Surface area equals heat. But, I would like to extend the contra flow up much higher than anything I have seen to provide the surface area. That may not be workable.

Here's another interesting site:

http://www.soapstoneheating.com/gallery.php

Had a peek at your book list and I'm going to pass. A few years ago, I got a bug in me to put in a small vineyard. I bought and read over a dozen books and I found that everyone had great ideas that worked perfectly for them, but they all contradicted each other. So I am doing what I think works best and we'll have to wait and see. Masonry Heaters are not something to create using trial and error but if I am going to work with one of the 3 local mason who specialize in this work, it's better that my head is not filled with a ton of ideas or they will not want to work for me. I've had people hire me that want to tell me how to do my work and it's never a pretty sight. Good to have enough knowledge to ask important questions at the beginning, then shut up.

Here's another interesting site:

http://www.soapstoneheating.com/gallery.php

Had a peek at your book list and I'm going to pass. A few years ago, I got a bug in me to put in a small vineyard. I bought and read over a dozen books and I found that everyone had great ideas that worked perfectly for them, but they all contradicted each other. So I am doing what I think works best and we'll have to wait and see. Masonry Heaters are not something to create using trial and error but if I am going to work with one of the 3 local mason who specialize in this work, it's better that my head is not filled with a ton of ideas or they will not want to work for me. I've had people hire me that want to tell me how to do my work and it's never a pretty sight. Good to have enough knowledge to ask important questions at the beginning, then shut up.

Kosmik

Member

I think getting a professional to design it is a good idea. Probably what I will do, or use pre-made plans.

A little math involved, especially with your passive solar.

If they degree swing in that room is great enough, you may not want a 'masonry heater' perse, but more of a kachelofen, hybrid iron stove, soapstone stove...

The masonry heater usually is designed for continuous output. Which makes them less desirable as heaters where you have erradic or intermittent heating needs. Or it may just mean a smaller heater fired in the afternoon to take the chill off will get er done, if the room still needs daytime heat, it could be designed to work off one or two firings. Generally the more responsive you want it, the less mass it will be (but materials can be a big factor also).

The nice thing is, since it's masonry, the design possibilities are almost endless.

I hear you about ideas, they are hard to contain.

But these books have been good for me in seeing all the different designs that in America we lump together as 'Masonry Heaters'.

Sounds like you have the right amount of constraints for a pro to design it.

"I want it to heat this room and fit here and look nice".

I think the books have helped me contrast to pros and cons of different materials and designs (especially since cost becomes a major factor). One thing that becomes clear is there is no ONE best stove. Money no object...Soapstone veneer and benches, baby! Some might depend on what I can find salvaged or to quarry. Of course there is a reason you see so many brick veneers (cheap and labor saving), if the look fits the room.

The first book was really good at being a "tour" of the different types.

The second is filled with bunches of pretty pictures (lots from NE USA/ SE Canada).

Both may fill your head with too many ideas, but it is nice to see what others have done, helps me envision all the possibilities.

You have quite a few different resources there, the pictures I've seen of their work look nice.

Other thing they may suggest a different location for the heater. If you're open to it, I'd keep an eye out for other (more interior) spots to put it. They will put it against exterior walls, but you get the most out of them when they aren't blocked by a wall, especially a cold wall, FWIW.

But being open to what the professionals have to suggest will probably make for a very warm, comfortable room.

A little math involved, especially with your passive solar.

If they degree swing in that room is great enough, you may not want a 'masonry heater' perse, but more of a kachelofen, hybrid iron stove, soapstone stove...

The masonry heater usually is designed for continuous output. Which makes them less desirable as heaters where you have erradic or intermittent heating needs. Or it may just mean a smaller heater fired in the afternoon to take the chill off will get er done, if the room still needs daytime heat, it could be designed to work off one or two firings. Generally the more responsive you want it, the less mass it will be (but materials can be a big factor also).

The nice thing is, since it's masonry, the design possibilities are almost endless.

I hear you about ideas, they are hard to contain.

But these books have been good for me in seeing all the different designs that in America we lump together as 'Masonry Heaters'.

Sounds like you have the right amount of constraints for a pro to design it.

"I want it to heat this room and fit here and look nice".

I think the books have helped me contrast to pros and cons of different materials and designs (especially since cost becomes a major factor). One thing that becomes clear is there is no ONE best stove. Money no object...Soapstone veneer and benches, baby! Some might depend on what I can find salvaged or to quarry. Of course there is a reason you see so many brick veneers (cheap and labor saving), if the look fits the room.

The first book was really good at being a "tour" of the different types.

The second is filled with bunches of pretty pictures (lots from NE USA/ SE Canada).

Both may fill your head with too many ideas, but it is nice to see what others have done, helps me envision all the possibilities.

You have quite a few different resources there, the pictures I've seen of their work look nice.

Other thing they may suggest a different location for the heater. If you're open to it, I'd keep an eye out for other (more interior) spots to put it. They will put it against exterior walls, but you get the most out of them when they aren't blocked by a wall, especially a cold wall, FWIW.

But being open to what the professionals have to suggest will probably make for a very warm, comfortable room.

Actually a Progress Hybrid was at the top of my list until I came upon the masonry heaters here on this forum. The idea of continuous heat is a big factor and if it's going to be a sunny day, it's easy to not put a new load in until later in the afternoon. Our stove now is on almost continuously I bring it down in temps just to clean out the ashes. Even with it being sunny today and yesterday, the super cold and wind conditions temper the solar gains. Yes, solar is great but when it's this frigid outside, the stove is always on low as a supplement.

Changing locations is something I have considered as I know an exterior wall is not the best but I think there is very little choice. The exterior wall is currently R34 but if I do put it there, I think I would rip out the fibreglass and spray foam in the wall so it would be R50+ and I can install a heat baffle at the same time. I have seen designs that are 5" offset from an exterior wall and that may be workable but not preferred. Seems like 5" would be a great place for cob webs and spiders. We have one spot that would be perfect in the middle of the room but the fire door would face the wrong way and no one would see it. Not good aesthetically but better heat-wise. I have to balance both. I'm not keen on some of the heaters I have seen. They are just butt ugly IMHO. I definitely want something that is a focal point to the room. A good one, not an ugly one.

Changing locations is something I have considered as I know an exterior wall is not the best but I think there is very little choice. The exterior wall is currently R34 but if I do put it there, I think I would rip out the fibreglass and spray foam in the wall so it would be R50+ and I can install a heat baffle at the same time. I have seen designs that are 5" offset from an exterior wall and that may be workable but not preferred. Seems like 5" would be a great place for cob webs and spiders. We have one spot that would be perfect in the middle of the room but the fire door would face the wrong way and no one would see it. Not good aesthetically but better heat-wise. I have to balance both. I'm not keen on some of the heaters I have seen. They are just butt ugly IMHO. I definitely want something that is a focal point to the room. A good one, not an ugly one.

Anybody else remember this guy? He came on here saying how great masonary heaters were and he was going to build one in a house that he was building. I thought he had even started getting some supplies and then nothing. Was curious if he ever followed through.

smithm1979,

I just saw this post. Sorry for not replying but I was on a retreat for a while and had no internet access. I'm still on "fire" for masonry heaters, and have been learning as much as possible. I attended a masonry heater build in Las Vegas sponsored by the masonry heater association (MHA). I made a post about this with some pictures. Building a masonry heater wasn't as complicated as I imagined it to be.

I bet there are members on this site who could build one right now, if they had a general idea of what they were doing - like Hogwildz, Simonkenton, & EMB550. Basic concepts one needs to know about masonry heaters if one wants to build them,

* they are composed of 2 main parts

* an inner part called a core

* an outer part (I think of it as a shell)

For all practical purposes the core is built out of firebricks. Firebrick comes in many duty statuses, ie low, medium, high, super duty. Generally, medium duty firebrick are used but some masons are using super duty for parts of the core. Time will tell how thermal shock effects these high/super duty bricks. Cost is usually the limiting factor with firebricks - lower duty is cheaper, generally.

To build a masonry heater (MH) a person has to be aware of the following things,

* the foundation under the MH - in my case 10" of concrete w/rebar. On houses with basements, masons will build a masonry rectangular mass from the basement floor to the living floor, and than build the MH on top of this rectangular basement support. Or steel beams can be used.

* MH's are radiant heaters. They do best in smaller to medium sized open floor plan houses that are well insulated. If you live in a large older ranch style house a wood stove with its convective heat would probably work better. Also MH's do well in cathedral ceiling type houses due to the nature of radiant heat.

Last edited:

Also when constructing a masonry heater the builder has to keep some things in his/her mind,

* the inner part, the core, gets very hot (up to 2000 F) thus this core will need to be given room to expand both vertically and horizontally - and this must be built in.

* thus the core part must be wrapped in mineral wool, cardboard, or fiberglass. 1/4" gap between the core and shell seems to work (cardboard width).

*the mh must have a way to get over-air to the burning fire. This is done by having a channel below the door. Air is let in or out by opening a grate. Under-air (coming up through the ash grate in the firebox) is a no no. You must be able to stop this under air. Or build a MH without a grate so you don't have to worry about it.

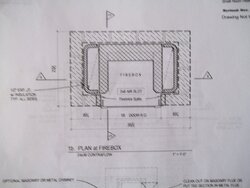

Your basically building a solid platform for the firebox. And under the firebox, channels for the gas to flow into the stove pipe. And, above the firebox your using more firebrick to make a narrower and narrower passage with a smallish opening at the top. The smoke/gases back up here and secondary burn occurs. The heated gases than start traveling through the flue channels (more secondary burn). These channels can be vertical or horizontal (many configurations).

The exhaust than goes out the stove pipe which can be at the base or the top of the masonry heater. There is a ratio of the total length of flue channel and chimney for best burn.

* the inner part, the core, gets very hot (up to 2000 F) thus this core will need to be given room to expand both vertically and horizontally - and this must be built in.

* thus the core part must be wrapped in mineral wool, cardboard, or fiberglass. 1/4" gap between the core and shell seems to work (cardboard width).

*the mh must have a way to get over-air to the burning fire. This is done by having a channel below the door. Air is let in or out by opening a grate. Under-air (coming up through the ash grate in the firebox) is a no no. You must be able to stop this under air. Or build a MH without a grate so you don't have to worry about it.

Your basically building a solid platform for the firebox. And under the firebox, channels for the gas to flow into the stove pipe. And, above the firebox your using more firebrick to make a narrower and narrower passage with a smallish opening at the top. The smoke/gases back up here and secondary burn occurs. The heated gases than start traveling through the flue channels (more secondary burn). These channels can be vertical or horizontal (many configurations).

The exhaust than goes out the stove pipe which can be at the base or the top of the masonry heater. There is a ratio of the total length of flue channel and chimney for best burn.

Last edited:

Generally the inner part the core is built first. Than it is wrapped. Than the outer shell is put up with cleanouts. Next, the door is installed. Finally, the stovepipe/thermal mass chimney. A masonry heater doesn't need an ash grate. They burn so hot that there isn't a lot of ash so just scooping it out would work fine.

The inner part, the core, is of firebrick usually but soapstone and refractrory cement pieces have been used, too. The outer part, the shell, is different because it can be constructed of many materials. Basically, anything that has a thermal mass to it and absorbs heat - rocks, bricks, cement blocks, stucco, tile, etc....

The price killer for masonry heaters come from expensive outer materials and the door. A self builder would be smart to just gather rocks or bricks for free (or at a low cost) and use them. The door is another matter. There is a company in China that says they are building doors to German standards. And these doors are inexpensive - like $50 to $150. The problem is that you have to order a bunch of them at once. I would like to see if these doors are usable. Maybe find some others who all want to go in on some doors.

The other cost is the firebrick. It really isn't that expensive - like $200 or $300. Remember you are only using it in the core. If you live in the midwest, like PA, IL or Ohio you have it made for firebrick (Alsey refractories - IL, Whitacre-Greer - Ohio?). If you live out west, like me, getting the right kind of firebrick is more difficult.

You need a few other things, like refractory cement and mortar. Ya, building a masonry heater is going to require the transport of from 4000 to 10000 pounds of materials so expect to work. And it will take more than a day to construct.

But you could have something like this in the end,

The inner part, the core, is of firebrick usually but soapstone and refractrory cement pieces have been used, too. The outer part, the shell, is different because it can be constructed of many materials. Basically, anything that has a thermal mass to it and absorbs heat - rocks, bricks, cement blocks, stucco, tile, etc....

The price killer for masonry heaters come from expensive outer materials and the door. A self builder would be smart to just gather rocks or bricks for free (or at a low cost) and use them. The door is another matter. There is a company in China that says they are building doors to German standards. And these doors are inexpensive - like $50 to $150. The problem is that you have to order a bunch of them at once. I would like to see if these doors are usable. Maybe find some others who all want to go in on some doors.

The other cost is the firebrick. It really isn't that expensive - like $200 or $300. Remember you are only using it in the core. If you live in the midwest, like PA, IL or Ohio you have it made for firebrick (Alsey refractories - IL, Whitacre-Greer - Ohio?). If you live out west, like me, getting the right kind of firebrick is more difficult.

You need a few other things, like refractory cement and mortar. Ya, building a masonry heater is going to require the transport of from 4000 to 10000 pounds of materials so expect to work. And it will take more than a day to construct.

But you could have something like this in the end,

Last edited:

We have friends Downeast who have a masonry heater. They love it. As spec.'d above, theirs is centrally located in a modest home with an "open" concept floor plan. Theirs has a stove on the kitchen side of the heater also. If memory serves me correctly, they burn 4 cord/season (could be wrong about that) and the heater is their primary source of heat (although they have a back up system). I know they begin firing the heater pretty early in the season as it takes time to get it "up to temperature" and once its up and running they have to keep it fed to maintain the heat.

VERY cool way to heat a home with wood! and they can be really handsome focal points in a living area.

VERY cool way to heat a home with wood! and they can be really handsome focal points in a living area.

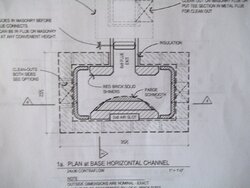

Bobbin, This is what the masonry heater association handed me when I went to Las Vegas, Nevada, to watch/assist in the build of a small masonry heater - 15 pages of plans. And I got a 3 or 4 page booklet, too. It explains what a masonry heater is (see scans). And I guess they have free pizza oven plans on their website - mha.com (see first scan with on-line address).

Bobbin, This is what the masonry heater association handed me when I went to Las Vegas, Nevada, to watch/assist in the build of a small masonry heater - 15 pages of plans. And I got a 3 or 4 page booklet, too. It explains what a masonry heater is (see scans). And I guess they have free pizza oven plans on their website - mha.com (see first scan with on-line address).Attachments

Last edited:

Seasoned Oak

Minister of Fire

You can buy the cores. Iv seen some offers to sell ready made cores from some small operations. After that regular masonry skills should let you finish the rest.

You can buy the cores. Iv seen some offers to sell ready made cores from some small operations. After that regular masonry skills should let you finish the rest.

Cores are too expensive in my opinion. They are easier to assemble (one day) but they are 5 to 10 times pricier than if you used firebrick. And firebrick will last longer. Building a core out of firebrick is more intimidating because of the more pieces one has to put together. But if you've got the extra $$ a pre-made core makes things easier.

Seasoned Oak

Minister of Fire

Dont you need some kind of hi-temp insulation around the firebrick as well. THe idea of the insulated core is for a rapid rise in temps. Too much masonry around it and you have the firebricks wicking off the heat from the fire not allowing the super high temps to develop or causing a long warmup phase.

Iv seen proto types that use a combination of a core and a steel barrel for a lot of quick heat ,not much storage but quick heat.

Iv seen proto types that use a combination of a core and a steel barrel for a lot of quick heat ,not much storage but quick heat.

Dont you need some kind of hi-temp insulation around the firebrick as well. THe idea of the insulated core is for a rapid rise in temps. Too much masonry around it and you have the firebricks wicking off the heat from the fire not allowing the super high temps to develop or causing a long warmup phase.

Iv seen proto types that use a combination of a core and a steel barrel for a lot of quick heat ,not much storage but quick heat.

You want the shell to wick heat from the core and its fire. The outer surface of the shell is where you get your heat. It gets warm/hot but won't burn a toddler or pet who touches it. They do insulate the pizza ovens, though. In this case, like you said you want to get the temp high ASAP and keep it high. I wonder how hot a masonry heater would get if you surrounded it's core with insulating firebrick? Probably greater than 2000 F. You'ld be turning it into an incinerator.

Seasoned Oak

Minister of Fire

From what iv read,thats what you want, is a 2000 deg incinerator.Thats where you get your clean burn and extract all available heat energy from the wood. Its the downstream masonry that extracts all the heat and leaves the final flue gasses near room temp. If you try to take the heat too early in the process you lower the burn temp and dont get the cleanest possible burn these stoves are known for. This is assumptions iv made from what iv read,of course i could be missing something.

From what iv read,thats what you want, is a 2000 deg incinerator.Thats where you get your clean burn and extract all available heat energy from the wood. Its the downstream masonry that extracts all the heat and leaves the final flue gasses near room temp. If you try to take the heat too early in the process you lower the burn temp and dont get the cleanest possible burn these stoves are known for. This is assumptions iv made from what iv read,of course i could be missing something.

There is quite a bit of thermal mass that the fire's heat must go through in a typical 2-hour burn.

First there are a couple of layers of firebrick in the core - note the little cardboard spacers in the corners. These give the inner part of the core room to expand. And there is no mortar between these 2 layers of firebrick so they can 'slide'.

,

Secondly, there are flue channels on each side of the finished core. So on the masonry heater's short sides the heat must travel through 2 layers of firebrick and than into these side flue channels before it hits a gap and the outer shell. Notice the white vertical line between the core and these flue channels. This is another expansion joint.

Thirdly, there is a jacket of fiberglass or cardboard wrapped around the finished core - this wrap delays the heat transfer from the hot inner core to the outer shell. So S.O. it acts like you said as an insulator. But it also acts as an expansion joint. You light the fire, it slowly expands the core, the core expands vertically and horizontally, & it pushes outward and encounters this little 1/4" gap. In the picture shown fiberglass is used. One layer of fiberglass on each end and 4 layers front and back - (the front and back is where the most heat is so more expansion occurs there.)

And as you can see in the above picture there is a 3" or 4" layer that goes around the core - in this case clay brick. So, in a 2 or 3 hour burn the heat has a lot of thermal mass layers and a small gap to pass through before it can heat everything up. This is enough resistance to cause the firebox to get very hot - up to 1800 F.

Anyone who is going to try and build a masonry heater needs to understand expansion and how to provide space within the masonry heater to allow for this. If a person was to use regular clay bricks in the core? I think they would start cracking after a few burns.

Last edited:

I'm still not sure if a masonry heater is going to provide enough BTUs for my needs. In the research I've done, most masonry heaters are putting out less than 30,000 BTUs. HOWEVER, how do I related that to the BTUs of a wood stove? Sadly, the wood stove industry is swamped with misleading and inaccurate BTU numbers. I know my old preEPA VC is supposed to be putting out at least that much and I am running it above normal temps to get enough heat.

Lots of people on this forum seem to change stoves every few years, some more often. A masonry heater is definitely not something you want to install and decide a month later that it's not putting out enough heat. Building a masonry heater and then keeping a wood stove seems insane to me, let alone too costly.

Here's another link with some good info: http://www.stovemaster.com/files/masonry.pdf

and this: http://www.tempcast.com/pdf/Planning Guide 2012_web_.pdf

Lots of people on this forum seem to change stoves every few years, some more often. A masonry heater is definitely not something you want to install and decide a month later that it's not putting out enough heat. Building a masonry heater and then keeping a wood stove seems insane to me, let alone too costly.

Here's another link with some good info: http://www.stovemaster.com/files/masonry.pdf

and this: http://www.tempcast.com/pdf/Planning Guide 2012_web_.pdf

I'm still not sure if a masonry heater is going to provide enough BTUs for my needs. In the research I've done, most masonry heaters are putting out less than 30,000 BTUs. HOWEVER, how do I related that to the BTUs of a wood stove? Sadly, the wood stove industry is swamped with misleading and inaccurate BTU numbers. I know my old preEPA VC is supposed to be putting out at least that much and I am running it above normal temps to get enough heat.

Lots of people on this forum seem to change stoves every few years, some more often. A masonry heater is definitely not something you want to install and decide a month later that it's not putting out enough heat. Building a masonry heater and then keeping a wood stove seems insane to me, let alone too costly.

Here's another link with some good info: http://www.stovemaster.com/files/masonry.pdf

and this: http://www.tempcast.com/pdf/Planning Guide 2012_web_.pdf

I was reading the temp-cast info provided and they mentioned building 2 heaters in a stack - that is one on top of the other, and each with a separate flue. Like one is in the basement and the other on the first floor. Or in a slab multi-story house, one on the first floor and the second on the second floor. Doug might this work in your house?

- Status

- Not open for further replies.

Similar threads

- Replies

- 71

- Views

- 3K

- Replies

- 20

- Views

- 1K

- Replies

- 4

- Views

- 659

- Replies

- 31

- Views

- 3K