First post... so sorry if this is in the wrong section.

Thought you guys might like to see what I came up with to heat my pool.

Started with a plain old 45gal barrel. Cut out a door.

Draft (although I screwed up the spacing)

Chimney and damper

Shelf

100' of 1/2" copper, in/out guages, garden hose fittings

In use

About average with stoking the fire every 30min-1hr or so.

The pool and how far away it is

Good results the 1st weekend. Got it up to 27C/83F from 22C/70F in 24 hrs.

Didn't stay shiney long!

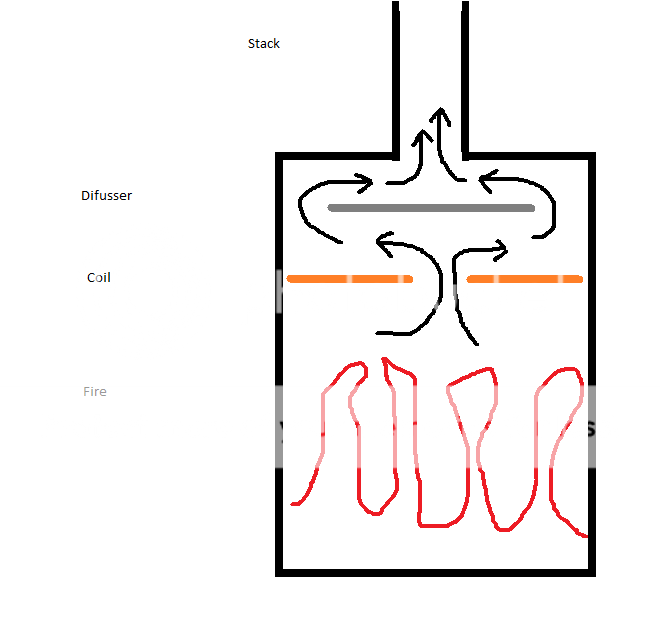

Built a damper to force the hot gases over the top of the coil before exiting. Made a significant difference.

Started playing with a waste oil burner

Cut out the center of the rotor and sat a 6" pipe on top.

Pre-heating with kerosene

introduced some waste oil

It did pick up more then this. Prob half way between this pic and the kerosene

Drip tube

Thought you guys might like to see what I came up with to heat my pool.

Started with a plain old 45gal barrel. Cut out a door.

Draft (although I screwed up the spacing)

Chimney and damper

Shelf

100' of 1/2" copper, in/out guages, garden hose fittings

In use

About average with stoking the fire every 30min-1hr or so.

The pool and how far away it is

Good results the 1st weekend. Got it up to 27C/83F from 22C/70F in 24 hrs.

Didn't stay shiney long!

Built a damper to force the hot gases over the top of the coil before exiting. Made a significant difference.

Started playing with a waste oil burner

Cut out the center of the rotor and sat a 6" pipe on top.

Pre-heating with kerosene

introduced some waste oil

It did pick up more then this. Prob half way between this pic and the kerosene

Drip tube