SO if you are pushing 4 gallons per minute through the 3/4 pex you are delivering 240 gallons per hour at 40,000 BTuH=2,400,000 per day per heating load making 4,800,000 in 24 hours theoretically.

The 4 GPM figure I used is for a "no water noise" in baseboard loops figure from the baseboard folks.

It is theoretically possible that the simple act of thermosyphoning may be enough to do this as you have 2,000 gallons of hot water in the garn and once it starts moving down hill with venting the line properly at the heating load using a boiler drain on the return line with a garden hose draped into a laundry sink you will not get all the air out on the first firing.

So a gallon of water weighs 8.34 pounds times 2,000 pounds is 16,680 pounds= (8 tons+680 pounds)

SO a single loop will have that water weight wanting to take advantage of the situation by simple gravity because water is lazy just like electricity it will go just about anywhere.

You seriously need to talk to a mechanical engineer about this and pay for an hour of his time and then you will have all your answers as a thermosyphon could work- remember water is pumped up hill and flows down hill naturally- our city water system has a very tall gravity drop and has worked this way for a hundred years now and it works very well.

Your looking at physics and head pressure at its finest hour with 2,000 gallons of water(8 plus tons) sitting above your heating load.

You have 2K (8 tons) of hot water at an altitude of 30 feet above the point of use

you have the $15 3/4" dual pex laying in the ground, you have 8 tons of water weight wanting to blow outof the garn tank creating pressure against the tank walls with one or two outlets not including the by boiler pass loop if you have one-you should just to make life easier and raduce cycling as your heating load(s) will stop calling for heat at one time or another.

Water pressure at sea level is 14.21 PSI depending- SO you have all that hot water with all its heat wanting to escape and waddle off someplace other than where it is.

So you have 3/4 Pex that can push more than 4 gallons per minute(more like 50) without batting an eye and the pressure is only regulated with the pex pipes inside diameter, the Pex pipe length, the back pressure created by the resistance in the pipe and the heating loops, and the return piping to the tank.

I want you to think of a marble as Dan would say, If it came to a Tee where would it go? How fast would it get there? How does gravity work in this case its all down hill like a bad day.

Hooking up one heating load and then a second in the same loop does a couple of things for you.

The first heating load strips heat out of the water and leaves the neighborhood for parts unknown(not really) the cooler water wanders over to the next house and the heating load in that house strips even more heat out of the water than the water waddles out for parts known only to you and the dual 3/4 pex back up hill to the garn barn and Viola the water is pushed back into the garn to be heated once more for the job of transferring 10,000 BTUh per gallon,

The gallon of water waddles down hill at a rate of 4 gallons per minute with its brothers and sisters and then creeps up hill to the garn at 240 gallons per hour 5,760 gallons per day in one loop that runs from one house to the next and back to the garn barn to be reheated so it can deliver 10,000 BTuH and the work continues

SO you have 8 plus tons of water pushing 33 pounds of water through the single loop(if its regulated) and its wanting to get out of the way for the rest of the water family to get through there.

I really want you to talk to a mechanical engineer as yoiu can take advantage of this with a really small circulator at the garn and the mechanical advantage you will have is in the 8 tons of hot water just sitting there.

Be the marble.

Do not forget that 1 GPM is 60 GPH and 1,440 gallons per day in the scheme of things and if you heat the garn to

180 high limit, gravity and a thermosyphon and the 8 tons of water weight in that tank are your friend.

The water is pushing from the garn to the first house then to the second house and then back to the garn.

Talk to a mechanical engineer and pay him for an hour of his time explaining your system, the altitude of the garn above the heating load and how you are examining pipe size for pex etc., and then go from there and you should have an answer to your issues. and you just may be able to thermosyphon to deliver heat to your heating loads.

Just think of how lazy the water family will be if 8K of additional hot water(33 tons+-) is pushing its family down hill in that 3/4 pex and wanting to get there, wherever there is.

Think like the marble, think of the garn as a simple platform scale with a pail of marbles that will slide down a pipe, think of a pipe loop as a horse shoe and the marble has to follow the inside loop of the horse shoe if you roll it in the inside and its slick enough the marbles will roll right up and jump back in the bucket.

Its not the most eloquent expalanation but I am tired so....................

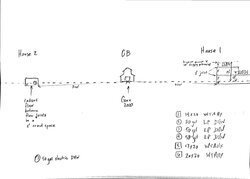

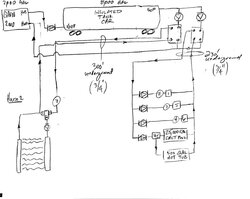

I will try to locate a mechanical engineer to discuss thermosyphoning in this context in more detail. I'd like to clarify that the Garn Barn (GB) slab is only 3' above house 1 and house 2 grades, not 30'. I was hoping 30' was a typo in your analysis, but please forgive me if that wasn't clear. I've attached a diagram attempting to illustrate this further. I tried to draw to scale as much as possible. I can draw the houses larger if my writing is too small to be clear. Also, the highest point in the system for house 1 is 5' above the floor of the attic that is above the 2nd floor (23' above the level of the Garn Barn slab) where the 4 and 5 ton LP furnace supply plenums (17x20 and 20x20 WTAHX) are 5' above that floor.

Don't get me wrong, I'd absolutely

LOVE to run the hot water from GB to house 1, and back past the GB all the way to house 2 prior to returning to the GB because house 2 only needs ~110F for radiant floor heating. This is how I originally though the system could be designed. I guess the downside to putting both homes in series, aside from the head loss issue, is that if one house is down, both houses likely would be down. Please correct me if I'm wrong, but I would think the most likely reason for the system to go down, assuming a leak-proof, pressure-checked, installation, would be a bad pump. That solution could be as simple as keeping 2 of each circulator/zone valve, one for backup if the corresponding operating unit fails.

Like maple1, I just can't see how to overcome this kind of head loss using small circulators and 1-1/4" or 1-1/2" logstor, much less 3/4" logstor. That's why I thought I'd need to break the install up into house 1 this year and house 2 next year. I guess I could possibly use larger circulators, but I was trying to use small ones if possible because I'm interested in minimizing power consumption in the event that I run the whole thing one day on solar.

As I understand, a reasonable estimate of head loss is:

Head loss = length of the longest loop * 1.5 (to account for resistance of fittings, HX's, bends in the pex, etc.) * 0.04 (all water with no glycol)

Head loss for house 1

560' * 1.5 * 0.04 =

34 feet of head (barn to highest and furthest points in house 1, and back to barn),

where 560' = [230' (GB to house 1) + 50' (distance from buried dualpex up into the attic and all the way over to the 17x20 and 20x20 WTAHX)]*2

Head loss for house 2

900' * 1.5 * 0.04 =

54 feet of head (GB to radiant supply manifolds, through any 300' loop, back to return manifold, and back to GB)

That is a rather large head loss for either circuit alone, much less combined:

34 + 54 =

88 feet of head

BTW, these head loss numbers seem to correlate with the Garn Design Manual. Referring to pages 13 and 14, a system designed with 20F dT's could flow hot water through 0.678" ID barrier pex (i.e. logstor 3/4") at 3GPM and 4.5GPM and deliver 30MBH (4 feet of head per 100') and 45MBH (6 feet of head per 100'), respectively.

At the 3GPM flow rate, a perfectly straight 560' pex pipe would see:

560' * (4FOH / 100') = 22.4 FOH

Similarly:

560' * (6FOH / 100') = 33.6 FOH

900' * (4FOH / 100') = 36 FOH

900' * (6FOH / 100') = 54 FOH

Add 50% of these values to themselves (the 1.5 figure in the calculations above) and you're in the same ballpark

As a side note, another reason I like your system description is that I don't plan to run glycol and the bypass allows for continual flow which would minimize any risk of lines freezing as long as there is no power outage. My planned LP backup generator for house 1 could provide that assurance because I'm running a 200 amp service from house 1 to the GB. The electrician can put all Garn and house 1 circulators, zone valves, etc. on that generator. House 2 already has a gasoline backup generator to do the same there.

Can you please provide some diagrams illustrating how a 3/4" system could be configured to do this?

!

!