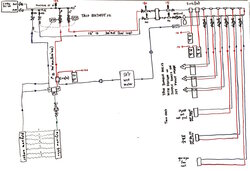

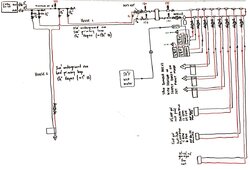

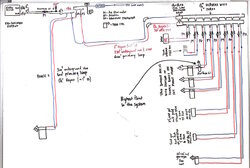

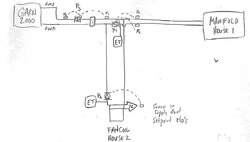

If you do the Logstor 1.5" you have a better situation than 1.5" Uponor. 1.5" logstor has an ID of 1.6" ID, better than the number I was using. if you do to and from the GB with 1.5" to house #1, you have a head loss of 11' at 600LF of pipe and 15 GPM.

that's way better.

house 2 at 600 feet would need lower flow rate most of the time, as the floor loops can mix the temp down to 100F probably.

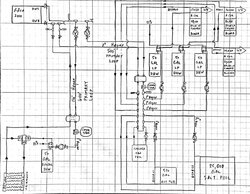

you won't use one pump to pump the entire 900 feet with house 2, you'd use one pump to move the 600' of 1.5" pipe, and do as maple suggested, connect a pair of closely spaced tees with another circulator pushing thru the floor loops when there is a heat call for any particular zone. or you use a flat plate heat exchanger in the building (could be either the GB or house 1) and run the heating loops pressurized. (as a contractor this is what I would do, because if there are air problems in the floor loops, I have to go back and fix it and that costs the price of a heat exchanger the first time I have to go back.)

on a separate topic, while you're waiting for Dan's books (and they're worth the wait, if nothing else, for the pickle story) read Caleffi's Idronics series. google them (they're free PDFs) and read them in order, and you'll have a really decent handle on what is going on in hydronics. the ones that deal with topics you don't particularly care about, just skim and look at the nice pictures.

cheers,

karl

.

.