Hey all,

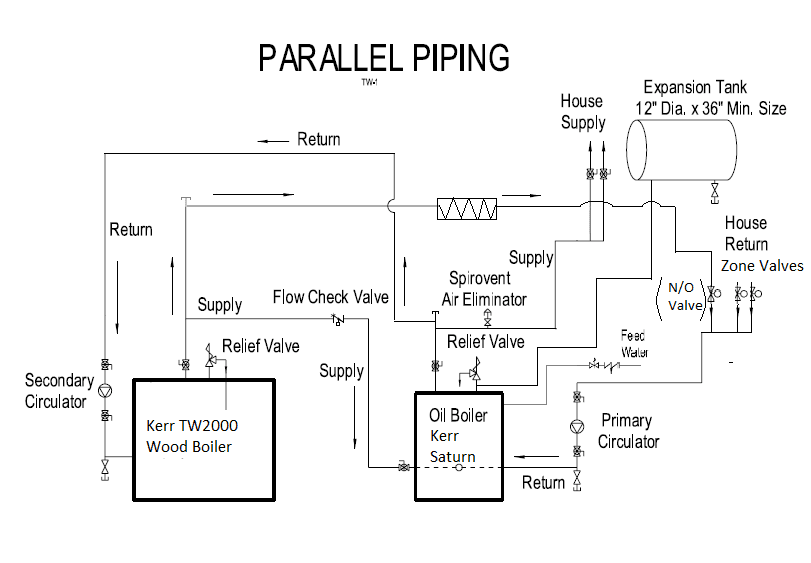

Recently finished connecting my Kerr Tw2000 wood boiler to my Kerr saturn oil fired boiler, Setup is in my garage and feeds to the house about 20 ft away. Went with supply on each to the return of the other, with a circ between the oil supply and wood return. Plan is to solely use wood unless I'm away for a day or two. Wood should keep the water in the oil boiler hot, and the oil boiler should behave normally, supplying the house with heat with it's own circ. Only wiring connecting the two is the end switch on the N/O valve to TT on oil boiler aquastat, and of course common power supply.

On the wood boiler:

Single acting aquastat controls that circ, have it set at 175°F.

Low setting on dual aquastat is at 180° to close the air damper

High is at 205° to open safety zone

On the oil Boiler

High is set at 190

Low is set at 170

Diff is 15

The problem I'm having is that the wood boiler gets to 180 and stays there...circ feeds to the oil boiler and takes a long time to rise water temp high enough to start the circ feeding the house...when it finally does, it runs for 2 minutes tops and shut down because water temp has dropped to 160°. Return pipe from house gets too hot to touch for more than a few seconds quickly.

My baseboard rads get warm, but only for a short time and are not heating the house. System works fine when I run just the oil fired boiler.

The temp in the wood boiler doesn't really change much, it may drop below the circ cutoff briefly near the end of the burn cycle, but it's taking roughly 25 minutes for the water temp in the oil boiler to recover.

I'll try attaching a piping schematic almost identical to my setup. All piping is 1-1/4", except for a short piece of 1" copper between wood supply and oil return(which I'm very suspicious of being the culprit of the slow rise)

Thanks

Recently finished connecting my Kerr Tw2000 wood boiler to my Kerr saturn oil fired boiler, Setup is in my garage and feeds to the house about 20 ft away. Went with supply on each to the return of the other, with a circ between the oil supply and wood return. Plan is to solely use wood unless I'm away for a day or two. Wood should keep the water in the oil boiler hot, and the oil boiler should behave normally, supplying the house with heat with it's own circ. Only wiring connecting the two is the end switch on the N/O valve to TT on oil boiler aquastat, and of course common power supply.

On the wood boiler:

Single acting aquastat controls that circ, have it set at 175°F.

Low setting on dual aquastat is at 180° to close the air damper

High is at 205° to open safety zone

On the oil Boiler

High is set at 190

Low is set at 170

Diff is 15

The problem I'm having is that the wood boiler gets to 180 and stays there...circ feeds to the oil boiler and takes a long time to rise water temp high enough to start the circ feeding the house...when it finally does, it runs for 2 minutes tops and shut down because water temp has dropped to 160°. Return pipe from house gets too hot to touch for more than a few seconds quickly.

My baseboard rads get warm, but only for a short time and are not heating the house. System works fine when I run just the oil fired boiler.

The temp in the wood boiler doesn't really change much, it may drop below the circ cutoff briefly near the end of the burn cycle, but it's taking roughly 25 minutes for the water temp in the oil boiler to recover.

I'll try attaching a piping schematic almost identical to my setup. All piping is 1-1/4", except for a short piece of 1" copper between wood supply and oil return(which I'm very suspicious of being the culprit of the slow rise)

Thanks