Hey everyone.

I am looking for some feedback on my installation of a Supreme Volcano Plus fireplace insert. It ships with their new Circulating Chamber (see attachment) which is essentially a metal surround you are meant to fasten into your masonry.

What I am hoping to do is build out 12" from my wall to accommodate built bookshelves on either side. This of course brings the insert that far away from my existing fireplace and chimney. I will probably have to take a couple bricks out to allow the flex liner to run on a desired angle up into the exterior chimney.

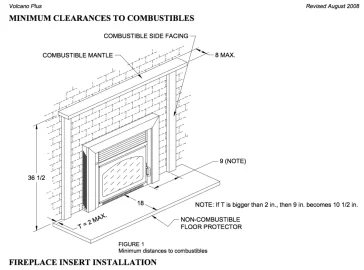

I will still be installing a fixing plate to seal the chimney, but my concern lies around the part of the firebox that will not be surrounded by brick. My first thought is to frame out a new wall 12" from the old one and the existing fireplace opening using metal studs around the fire area and fire-rated cement board, fasten the new circulating chamber to the metal studs.

Do I need to close in the area above (horizontal) the circulating chamber/insert with a couple layers of cement board and run that right into the brick? I could leave a gap for some roxul in there too. I don't want a lot of heat being transferred above the chamber because there will be a mantel going up and above that most likely a TV. (with clearances in mind) The volcano plus does have a couple blowers in it as well.

I haven't come across anyone installing a wood burning insert in anything but completely setback in a masonry fireplace. Is what I want to do even safe with this wood insert?

Manual is here if you are interested:

http://www.supremem.com/docs/Volcano Plus manual (english) Modified.pdf

Thanks in advance for your help and thoughts!

James

I am looking for some feedback on my installation of a Supreme Volcano Plus fireplace insert. It ships with their new Circulating Chamber (see attachment) which is essentially a metal surround you are meant to fasten into your masonry.

What I am hoping to do is build out 12" from my wall to accommodate built bookshelves on either side. This of course brings the insert that far away from my existing fireplace and chimney. I will probably have to take a couple bricks out to allow the flex liner to run on a desired angle up into the exterior chimney.

I will still be installing a fixing plate to seal the chimney, but my concern lies around the part of the firebox that will not be surrounded by brick. My first thought is to frame out a new wall 12" from the old one and the existing fireplace opening using metal studs around the fire area and fire-rated cement board, fasten the new circulating chamber to the metal studs.

Do I need to close in the area above (horizontal) the circulating chamber/insert with a couple layers of cement board and run that right into the brick? I could leave a gap for some roxul in there too. I don't want a lot of heat being transferred above the chamber because there will be a mantel going up and above that most likely a TV. (with clearances in mind) The volcano plus does have a couple blowers in it as well.

I haven't come across anyone installing a wood burning insert in anything but completely setback in a masonry fireplace. Is what I want to do even safe with this wood insert?

Manual is here if you are interested:

http://www.supremem.com/docs/Volcano Plus manual (english) Modified.pdf

Thanks in advance for your help and thoughts!

James