my auger failed, put a new one in started fire everything appeared to be working fine walked away herd a click like a fuse popping and the stove was dead.... no lights on control board. I have power to stove is there a fuse ? Or reset ? Or did I blow my board..

Whitfield died?

- Thread starter Bugs

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JRemington

Minister of Fire

heat seeker

Minister of Fire

Agree - there should be at least one fuse on the circuit board. Before powering the stove back up, look very carefully for wires that you may have pinched or otherwise damaged when changing the motor. I'd check the wiring for the room blower first, then everywhere else.

Agree - there should be at least one fuse on the circuit board. Before powering the stove back up, look very carefully for wires that you may have pinched or otherwise damaged when changing the motor. I'd check the wiring for the room blower first, then everywhere else.

Thank you for your replies it appears on doing some research there should be a fuse on the bottom of the controller,

I will check that fuse and the wiring as you suggested.

JRemington

Minister of Fire

Now I think about it we had a stove last year that was blowing fuses. I finally found it by unplugging the power to the low limit, high limit and vacuum switches. I also unhooked the power to the auger. I started the stove and reconnected everything one at a time. When I connected the auger the fuse blew. It ended up a "new" auger motor had a short in it.

Now I think about it we had a stove last year that was blowing fuses. I finally found it by unplugging the power to the low limit, high limit and vacuum switches. I also unhooked the power to the auger. I started the stove and reconnected everything one at a time. When I connected the auger the fuse blew. It ended up a "new" auger motor had a short in it.

Well.. I put a new fuse in, stove powers up but now the auger runs continuously even with auger power off..

Well.. I put a new fuse in, stove powers up but now the auger runs continuously even with auger power off..

And it just blew the fuse again :-( bad new auger ?

When I first put the new auger in it all appeared to be working fine, then it blew the fuse after about 15 min. And now auger runs continuously even without turning auger on? And then blows fuse.

Last edited:

Stovensen

Minister of Fire

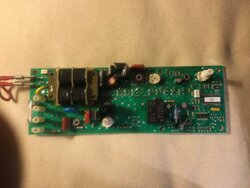

A surge on your power line could have "zapped" several components on the control board. Now, you don't inform us the exact stove model and year of making, but the newer Whitfield control boards do have minimal built in surge protection. The on board surge protecting component is a varistor ( aka VDR=voltage dependent resistor ). On this picture of a control board from a 1998 Whitfield Quest Plus you see the varistor ( red disk ) just below the mains transformer. Also, we see the main fuse at the leftmost side. The fuse is in series with the main power loop. In order to protect against overloads the fuse also has to be the very first component in the circuitry. Right after the fuse, the VDR is in parallel with the power line. This enables the VDR to shunt out any destructive high voltages. Unfortunately VDRs may turn into permanent shorts, if they have been exposed to several high voltage surges. Note: This condition will blow the fuse!

And another thing: The auger-triac on the board is most likely zapped as well, since the auger motor runs constantly.

Your control board needs some repair, but the components mentioned above are standard components available in most electronic shops.

Detailed picture of the control board in a 1998 Whitfield Quest Plus:

And another thing: The auger-triac on the board is most likely zapped as well, since the auger motor runs constantly.

Your control board needs some repair, but the components mentioned above are standard components available in most electronic shops.

Detailed picture of the control board in a 1998 Whitfield Quest Plus:

Last edited:

JRemington

Minister of Fire

Do you have the stove plugged into a good surge protector? Also, do you still have the old auger motor? If you do jump power to it and see if it runs constantly. The board controls the start up cycle and some stoves will run the auger continuously for a period during startup and fill the pot and then stop for a period. During startup you don't have control of the stove. I don't know the auger cycle for that stove. Have you looked for frayed or bad wires and made sure everything is connected properly?

Thanks for the reply

The stove is an advantage ll t manufacture date of 1991.

I had just replaced the auger motor it was working for several minutes then I heard the fuse pop.

Replaced the fuse the next day plugged it in everything looked good except auger was running continuously before I even started the auger. Runs continuously with auger on or off. Has the touch pad type controller.

The stove is an advantage ll t manufacture date of 1991.

I had just replaced the auger motor it was working for several minutes then I heard the fuse pop.

Replaced the fuse the next day plugged it in everything looked good except auger was running continuously before I even started the auger. Runs continuously with auger on or off. Has the touch pad type controller.

Last edited:

JRemington

Minister of Fire

That's an old stove. Are you saying the auger was running with the power turned off?

No, running with auger switch off.

Stovensen

Minister of Fire

The stove is an advantage ll t manufacture date of 1991.

Ok, so it has the newer touch pad control as opposed to the older boards with rotary knobs.

But we'll have to take a closer look inside your control board in order to locate and troubleshoot the components in question.

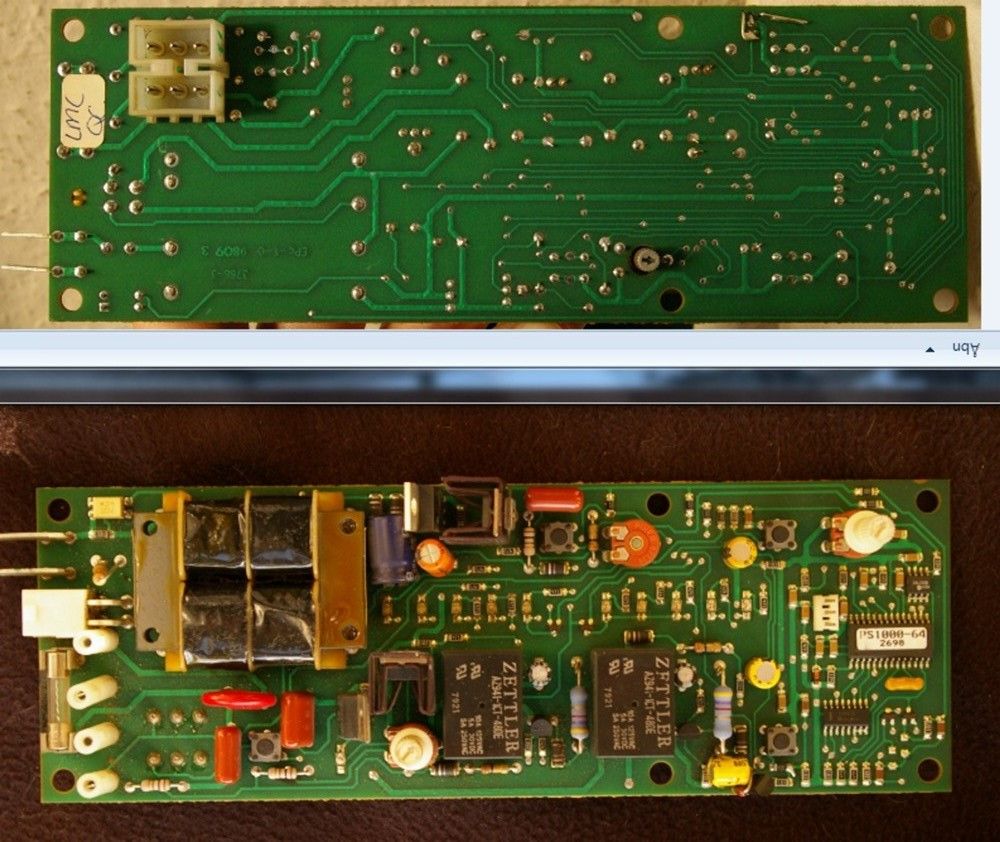

I searched the internet for a useful picture using different terms, and I found this picture of something that could be similar to your control board.

It is from an Advantage II, but we don't know the exact year, though.

Is the component layout on your control board similar to this?

I had just replaced the auger motor it was working for several minutes then I heard the fuse pop.

Replaced the fuse the next day plugged it in everything looked good except auger was running continuously before I even started the auger. Runs continuously with auger on or off.

This sequence of events has useful information. First we may conclude that the auger triac is fried ( = permanently shorted ), since the auger motor runs continously regardless of the toggle state of the control button.

Next conclusion is much more difficult.....we must figure out why the fuse popped and why it took several minutes before it popped.

My suspicion is still circling around the varistor ( the red disk below the transformer). In most cases, when they fail, they turn into permanent short circuits, but unstable intermediate states are possible, which could explain what happened with your stove.

Did you notice any smoke ( or smell of smoke ) from the control board in the minutes before the fuse popped?

Last edited:

You can get your control panel fixed by this person. E-mail him and tell him what happened. You would have to check that auger. Something blew the fuse and with you just replacing the auger.. something is up.

(Heatwave Electronics. ([email protected] ) 530-820-3700

(Heatwave Electronics. ([email protected] ) 530-820-3700

I will pull the back cover off and see if it is similar, I am concerned about the fuse blowing with the new auger though.

Just to check I plugged the old auger in and it ran continuously too. Not sure how to check the new auger for defects.

This stove has been working well for several weeks, until the auger malfunctioned.

Just to check I plugged the old auger in and it ran continuously too. Not sure how to check the new auger for defects.

This stove has been working well for several weeks, until the auger malfunctioned.

Stovensen

Minister of Fire

Here is a pic, mine is blue.

The blue varistor on your board is a 120VAC version and it could also be from another manufacturer, but the printed circuit boards on our stoves appear to be completely similar.

Mine is a 230 VAC version, so some components are different ( transformer, fuse, relays etc. ) Mine also came with factory installed igniter, which is why there's an extra relay. Your board has an empty space there.

The auger-triac is very close to the blue varistor. On mine the auger-triac is a MAC228 A6 from Motorola ( see picture ). Your line voltage is 120VAC, so another triac type could be used. Be sure to get the right type!

It's a bit difficult to unsolder components with more than two pins on a double sided circuit board. In this case the easiest way is to simply cut the pins with cutting pliers, and then unsolder the rest of the pins one at a time. A suction tool ( or solder wick ) is needed to clean the holes for any old tin before the new triac can be inserted and soldered. Take care not to overheat the ultrathin copper traces. This could destroy them.

Auger triac on my 1998 Quest Plus:

No apparent signs of hot spots

The varistor could be in an unstable intermediate state making short circuits, when it's in a bad mood. We just don't know. I suggest you unsolder it, and run the stove without it in the future. Instead you should buy an external surge protector. The better of these will protect your control board much more efficiently.

TrippLite IsoUltra:

To rule out any short circuits in the copper windings of the blower motors and auger motor you'll have to measure their respective copper resistances with an ohmmeter. The service manual will give you the exact details on how to do this. Link to service manual:

https://www.dropbox.com/s/sqla0k3x3...ntageII-T_AdvantageIII_TECH_TRAINING.pdf?dl=0

Good luck and take care. Keep us posted

Last edited:

My question, as a tech guy, who says the auger malfunctioned ? Did you test the old auger ?

I did not test it Per se but the motor was operating but it was not turning the gears. I could see that when it would run the armature Was pulling out an eight inch every time it ran, when I dis-assembled the gear box I could see the small motor gear was below the drive gear. The gears all looked good (no teeth missing). It was 25 years old I just figured it was tired. Here are pictures of the viristor and triac

Sounds like what happen to my original auger. The fiber washer on the back of the motor wore, and the motor slid back not making contact with the first gear. It would turn the gear some times, slip others. I just replaced the washer and it ran for another 5 years or so.

See what the guy at HeatWave says.. he fixes them all the time. Whatever powers the auger is shorted. You can run the new auger for some 5 min. They will get warm on straight runs. Just strange a new auger caused problems.. It somehow didn't short on something.

See what the guy at HeatWave says.. he fixes them all the time. Whatever powers the auger is shorted. You can run the new auger for some 5 min. They will get warm on straight runs. Just strange a new auger caused problems.. It somehow didn't short on something.

Sounds like what happen to my original auger. The fiber washer on the back of the motor wore, and the motor slid back not making contact with the first gear. It would turn the gear some times, slip others. I just replaced the washer and it ran for another 5 years or so.

See what the guy at HeatWave says.. he fixes them all the time. Whatever powers the auger is shorted. You can run the new auger for some 5 min. They will get warm on straight runs. Just strange a new auger caused problems.. It somehow didn't short on something.

That’s what is happening to mine...now it sounds like it shorted my board:-( not sure in my area where I can get replacement parts but I’ll start looking.. I have a good weller soldering iron just not sure how my skill level is. I’m an extra class ham but it’s been years..since I’ve worked on radios. I may fix the old auger to have a spare. Winter is here need to get this thing fixed. I paid 50.00 for the stove 30.00 for all the stainless stove pipe plus my time cleaning and installing. So I’m still in the black. Oh ya 110.00 for new auger.

Last edited:

Stovensen

Minister of Fire

I have a good weller soldering iron just not sure how my skill level is. I’m an extra class ham but it’s been years..since I’ve worked on radios.

This certainly is good news. I'm also a radio amateur ( call sign OZ7XRT ). Next step in troubleshooting your stove is to find out why the fuse popped, and why it took several minutes before it did. You know, we may be facing the worst nightmare of all technicians: A periodic failure! I'm still suspecting the varistor, but other things are in parallel: The primary winding of the transformer, the blower motors etc. Please check the service manual for the correct copper resistances of those electromagnetic field windings.

One question: Are you absolutely sure that the blown fuses had the correct ratings?

Good luck. Keep us posted

73 de OZ7XRT

Last edited:

This certainly is good news. I'm also a radio amateur ( call sign OZ7XRT ). Next step in troubleshooting your stove is to find out why the fuse popped, and why it took several minutes before it did. You know, we may be facing the worst nightmare of all technicians: A periodic failure! I'm still suspecting the varistor, but other things are in parallel: The primary winding of the transformer, the blower motors etc. Please check the service manual for the correct copper resistances of those electromagnetic field windings.

One question: Are you absolutely sure that the blown fuses had the correct ratings?

Good luck. Keep us posted

73 de OZ7XRT

Cool (call sign N7YZ) putting new varistor and triac. The stove had been working well until I put the new auger in.

Well, replaced the triac and veristor and it was working again yay ! 45 min. Then fuse blew again...this suks

Mt Bob

Minister of Fire

Similar threads

- Replies

- 29

- Views

- 548

- Replies

- 4

- Views

- 660

- Replies

- 3

- Views

- 1K

- Replies

- 8

- Views

- 912