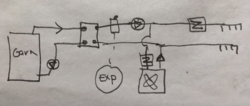

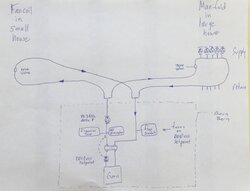

With three circulators as you suggest in the drawing your going to

have issues with the point of no pressure change even though you

do not have an air scoop and lots of air bubbles even though its an open system.

A little help from a B+G or TACO sales rep will solve this for you if you fax them a

drawing or drawings of your system.

Your trying to circumvent basic laws of hydraulics with your design and your going to lose circulators.

My drawing doesn't show air eliminators although I do have those planned for the closed side. The Garn-side of the FPHX is open, but I was under the impression that putting the circ down low would guard against cavitation.