Whitfield died?

- Thread starter Bugs

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mt Bob

Minister of Fire

Stovensen

Minister of Fire

Nice sharp pics. Working surfaces and bushing sure look worn, but nothing appears damaged.

This video has some useful info related to the inspection and upgrading from Oilite bronze to Nylatron bushing:

This video has some useful info related to the inspection and upgrading from Oilite bronze to Nylatron bushing:

Stovensen

Minister of Fire

Bugs, this kit is for sale very close to you. The kit contains both Nylatron bearing, endplate and gasket. The endplate is also an upgraded version with rubber bumper and pad, which should reduce auger noise.

https://www.ebay.com/itm/AUGER-BEAR...-STOVE-PP4010-12153900-13650072-/401052357998

Inspired by this thread, I checked the play on my auger shaft, and... there is some play. It is nine years, since I replaced the Nylatron bearing, so a replacement is needed. Unfortunately the seller on eBay does not ship to Denmark. Think I'll send them an email and ask if we can work out something.

https://www.ebay.com/itm/AUGER-BEAR...-STOVE-PP4010-12153900-13650072-/401052357998

Inspired by this thread, I checked the play on my auger shaft, and... there is some play. It is nine years, since I replaced the Nylatron bearing, so a replacement is needed. Unfortunately the seller on eBay does not ship to Denmark. Think I'll send them an email and ask if we can work out something.

Bugs, this kit is for sale very close to you. The kit contains both Nylatron bearing, endplate and gasket. The endplate is also an upgraded version with rubber bumper and pad, which should reduce auger noise.

https://www.ebay.com/itm/AUGER-BEAR...-STOVE-PP4010-12153900-13650072-/401052357998

Inspired by this thread, I checked the play on my auger shaft, and... there is some play. It is nine years, since I replaced the Nylatron bearing, so a replacement is needed. Unfortunately the seller on eBay does not ship to Denmark. Think I'll send them an email and ask if we can work out something.

Thanks, I did order one and it arrived today, I have amazon prime so freight was no charge and I got it the next day.

I’m going to install it today and try and solder a new triac in. I found my desoldering tool so I’ll give it a try, worse case is ruin my board.

Installed the new end plate, the old one was very sloppy, I could see a gap between the bushing and end plate. I am letting the stove run for awhile to see if the fuse blows with the auger running continuously. Not sure if it works that way with the triac already bad, but I would think if it overheated running in intermittent mode, it would overheat faster in continuous running (pretzel logic)

Well, that sucked last triac I had, got the center ribbon to hot started separating from the board but I was able to juryrig, it lasted 10 min and blew the fuse again, I’m so frustrated I could eat fried chicken.

Mt Bob

Minister of Fire

Did you add in the other fuses first?

No... I was so sure that the bad bushing was causing a major drag and overheating. I learned a big lesson maybe a very costly one, not sure this board can take the heat of another soldering job..already have a ribbon separating from the board that goes to the middle post on triac. Is there a way to check the resistance of the other components that might be the culprit? I’m just frustrated that the fuse isn’t protecting the triac, it made since what stovensen was saying.

Mt Bob

Minister of Fire

It could be the board itself,yes.Guy that posed here fixes them.If other fuses were there,you would have known.Might want to give this guy a call.No... I was so sure that the bad bushing was causing a major drag and overheating. I learned a big lesson maybe a very costly one, not sure this board can take the heat of another soldering job..already have a ribbon separating from the board that goes to the middle post on triac. Is there a way to check the resistance of the other components that might be the culprit? I’m just frustrated that the fuse isn’t protecting the triac, it made since what stovensen was saying.

(Heatwave Electronics. ([email protected] ) 530-820-3700

It could be the board itself,yes.Guy that posed here fixes them.If other fuses were there,you would have known.Might want to give this guy a call.

(Heatwave Electronics. ([email protected] ) 530-820-3700

Ya your right, I was being lazy, didn’t want to disconnect all the pipes and pull the stove out, and it may have cost me. Guess I was hoping for an easy fix. This thing was running perfectly until the first auger went out. Sometimes I thought I could hear it hanging up, so I ASSumed it was the bearing over heating the auger motor as mentioned. I’m not giving up on this stove yet.

Ssyko

Minister of Fire

Well, that sucked last triac I had, got the center ribbon to hot started separating from the board but I was able to juryrig, it lasted 10 min and blew the fuse again, I’m so frustrated I could eat fried chicken.

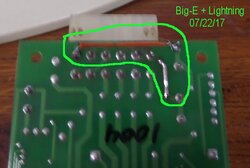

a small workaround for bad traces. cat5 cable single strand of copper wire (Orange Wire) for missing trace. or tin the trace with solder (trace that popped). see pic my old big e board before the Surge protector

Attachments

Mt Bob

Minister of Fire

Well.if you can fix board,put a fuse inline.You could try several things,pull auger motor,wire direct to outlet,run it,but I would not do it unless you add inline fuse,or,set motor on counter,hook ohm meter to one or both motor leads,one lead to motor/gearcase body,heat with hair dryer.Also,this is remote,as I do not know if the low limit is low or high voltage,unhook wires from low limit(leave in place),hook ohm meter to ground and one of terminals,heat with hair dryer,when snaps,see if grounding.Would be rare,but you do have a strange problem.

Ssyko

Minister of Fire

most limit switches are 115/220. but you can ck them for continuity with the hair drier/heat gun

Mt Bob

Minister of Fire

Yes,I know,but have you ever looked at an old whitfied wiring diagram?most limit switches are 115/220

Ssyko

Minister of Fire

Mt Bob

Minister of Fire

sometimes the snap switch goes into the control panel,lol,and lots of versions,quite a mess,here take a look. http://www.hearthtools.com/parts/whitfield_wire_diagrams.pdfMe no I have not. haven't had the need to

Ssyko

Minister of Fire

yes, i see what you mean. the relay was removed due to redundancy and the moved the limit switches to control board. is this control board multi layered? ok im not asking any more questions.. Bob I'll pick your brain in another thread.

Mt Bob

Minister of Fire

single layeryes, i see what you mean. the relay was removed due to redundancy and the moved the limit switches to control board. is this control board multi layered? ok im not asking any more questions.. Bob I'll pick your brain in another thread.

Ssyko

Minister of Fire

should be easy to repair then.if it isn't controled by a Prom. i would run in-line fuses to all the motors and leave them in line.

Ssyko

Minister of Fire

disregard! it is controlled by a prom. if higher voltage got past the triac going the wrong way (i don't see any diod's in line) it very likely disrupted the mechanical side of the prom.if it isn't controlled by a Prom

Mt Bob

Minister of Fire

LOL true,I doubt it flashed over unless took out traces.Almost everything has had prom's since the early 80'sdisregard! it is controlled by a prom. if higher voltage got past the triac going the wrong way (i don't see any diod's in line) it very likely disrupted the mechanical side of the prom.

Ssyko

Minister of Fire

Honestly I wouldn't do any more testing without in-line fuses. gotta find the culprit of the timed short.

Mt Bob

Minister of Fire

Ya he knows,especially if he wants to save that board,but it is due for the board upgrade----Honestly I wouldn't do any more testing without in-line fuses. gotta find the culprit of the timed short.

Ya he knows,especially if he wants to save that board,but it is due for the board upgrade----

And what is the board upgrade ? The trace is still there I had to solder it to the center post where it was originally everything is so small for my 60+ year eyes I’m not sure I have the talent required. I will need to order more triac and inline fuses any recommendations on inline fuses, I’ve used several kinds over the years for ham power.

Similar threads

- Replies

- 29

- Views

- 543

- Replies

- 4

- Views

- 660

- Replies

- 3

- Views

- 1K

- Replies

- 8

- Views

- 911